Product Description:

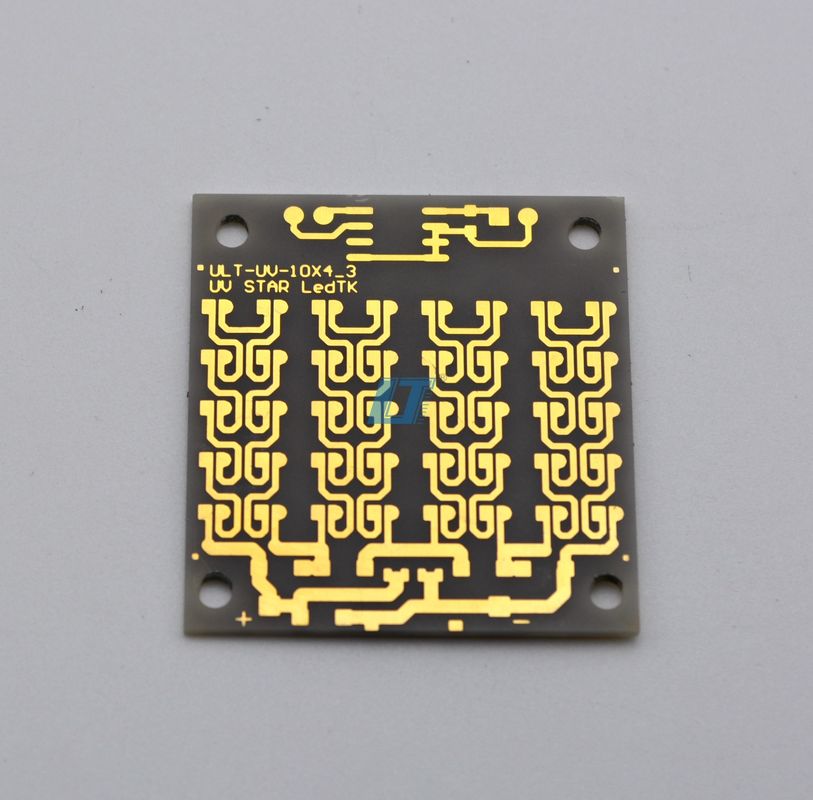

The Immersion Gold Ceramic PCB Board is a state-of-the-art printed circuit board (PCB) designed to meet the needs of high-performance electronics. This PCB leverages the unique properties of ceramic materials to ensure stability, reliability, and efficiency in a variety of applications. With dimensions of 22mm by 19mm, it is a compact solution that is capable of supporting sophisticated electronic designs. As a Ceramic Dielectric PCB, it boasts a dielectric constant of 6.0-10.0, which is indicative of its high signal integrity and reduced signal loss, making it ideal for high-frequency applications.

One of the key attributes of this ceramic PCB is its minimum line width and spacing of 0.1mm. This fine line technology enables the Immersion Gold Ceramic PCB Board to accommodate a higher density of circuits, which is critical for modern devices that require complex circuitry in a compact form factor. The high precision in line width and spacing ensures that the PCB can support intricate designs without compromising on the performance and reliability of the electronic device.

Furthermore, the Immersion Gold Ceramic PCB Board is not just a Ceramic Dielectric PCB, but also a Ceramic Thermal Management PCB. The inherent thermal properties of ceramic substrates provide superior heat dissipation compared to traditional FR-4 boards. This is particularly beneficial for power-intensive components and high-speed electronics where heat management is crucial. The efficient thermal management capability of the board ensures that the device operates within optimal temperature ranges, thereby extending the lifespan of the electronic components.

Another distinguishing feature of the Immersion Gold Ceramic PCB Board is its surface finish. The immersion gold process not only provides a flat surface that is ideal for fine-pitch components but also offers excellent solderability and corrosion resistance. This enhances the reliability of the PCB in harsh environments and ensures strong electrical connections between components. It is a Ceramic Hybrid PCB that combines the mechanical strength of ceramic materials with the conductive properties of immersion gold to deliver outstanding performance.

This PCB also comes with a comprehensive One-stop Service / OEM, DFM (Design for Manufacturability) service. Customers can benefit from a seamless experience, from design and prototyping to manufacturing and testing, all provided by experienced professionals who understand the nuances of working with ceramic materials. The DFM service ensures that the PCB is not only manufacturable at an optimal cost but also that it meets all the quality standards and functions as intended in the final product.

In conclusion, the Immersion Gold Ceramic PCB Board is an innovative solution that caters to the demanding needs of modern electronics. With its fine line width and spacing, excellent dielectric properties, superior thermal management, and robust surface finish, it is an ideal choice for applications requiring high reliability and performance. The one-stop service further enhances the value proposition of this product, making it a smart choice for OEMs looking for a high-quality Ceramic Hybrid PCB. Whether it's for advanced communication devices, medical equipment, or aerospace technology, this ceramic PCB stands out as a reliable foundation for cutting-edge electronic innovations.

Features:

- Product Name: Ceramic PCB Board

- Product Type: PCB&PCBAOEM,DFM

- Operating Temperature: -50°C To 150°C

- Service: One-stop Service / OEM,DFM

- Size: 2mm~200mm

- Dielectric Constant: 6.0-10.0

- Keywords: Ceramic Printed Circuit Board

- Keywords: Ceramic Dielectric PCB

- Keywords: High thermal conductivity Ceramic PCBs

Technical Parameters:

| Attribute |

Details |

| Dielectric Constant |

6.0-10.0 |

| Surface Finished |

Immersion Gold, nickel-palladium GOLD |

| Material |

Al2O3, ALN |

| Min Line Width/Spacing |

0.1mm |

| Layers |

1-8 Layers |

| Thermal Conductivity |

170 W/mK |

| Surface Technics |

ENIG, nickel-palladium GOLD |

| Pcb Name |

Immersion Gold Ceramic PCB Board |

| Size |

2mm~200mm |

| Product Type |

PCB&PCBA OEM, DFM |

Applications:

The Ceramic PCB Board, boasting an impressive thermal conductivity of 170 W/mK, is designed to meet the needs of high-performance electronics where efficient heat dissipation is paramount. Typical application occasions and scenarios for this product range from aerospace engineering to high-power LED lighting systems, where maintaining a lower operating temperature is crucial for reliability and longevity.

One of the primary scenarios where these PCBs are utilized is in the automotive industry. With the advancement of electric vehicles (EVs) and autonomous driving technology, the Ceramic Board with Copper Clad Laminate is increasingly sought after. This is due to its ability to handle the high temperature and power density that automotive electronics demand, ensuring that components such as power inverters and sensors operate within safe temperature ranges, from -50°C to 150°C.

Another critical application of the 170W/m·K ALN Ceramic PCBs is in high-power computing, including servers and high-performance CPUs. The superior thermal management capabilities of these PCBs help in dealing with the immense heat generated by these devices, thereby improving performance and preventing thermal throttling. The surface finished with Immersion Gold and nickel-palladium GLOD, along with surface technics like ENIG, enhance the PCB's durability and conductivity, which is essential for such demanding environments.

Additionally, these PCBs are also perfect for use in the medical field, especially in equipment where precision and reliability are non-negotiable. The high thermal conductivity allows for quicker heat dissipation in critical devices such as MRI machines and CT scanners. The ALN Ceramic PCBs' robustness and the ability to withstand high operating temperatures ensure that medical devices function accurately and without interruption.

For the aerospace industry, the Ceramic PCB Board can be a game-changer. Spacecraft and satellites require components that can survive extreme temperatures and conditions, and the Ceramic PCB Board's high thermal conductivity and wide operating temperature range make it an ideal choice. The one-stop service/OEM,DFM services associated with these PCBs streamline the integration of these high-quality boards into complex aerospace systems.

In summary, the Ceramic PCB Board is a versatile and high-performing solution for any industry requiring excellent thermal management and reliability. Its application in various scenarios is a testament to its durability, efficiency, and adaptability, making it an indispensable component in the advancement of modern electronics.

Customization:

We offer specialized Product Customization Services for the Immersion Gold Ceramic PCB Board . This high-performance board is designed to cater to the most demanding applications, featuring exceptional thermal conductivity of 170 W/mK , making it one of the top-performing 170W/m·K ALN Ceramic PCBs on the market. Its robustness is evident in its wide operating temperature range from -50°C to 150°C , ensuring stability and reliability under extreme conditions.

The precise dimensions of the PCB are 22mm*19mm , accommodating compact and efficient designs. Our boards are crafted from a high-grade Ceramic Glass Composite PCB material, offering a dielectric constant range of 6.0-10.0 to meet your specific insulation requirements.

Further enhancing the performance of our Ceramic PCB Board is the Copper Clad Laminate, which provides an excellent foundation for a variety of electronic components. The Ceramic Board with Copper Clad Laminate is tailored to deliver top-notch efficiency and durability for your electronic projects.

Support and Services:

Our Ceramic PCB Board comes with comprehensive product technical support and services, designed to provide our customers with an exceptional experience. Our support includes access to a wealth of online resources such as detailed product documentation, frequently asked questions (FAQs), and technical guides that cover everything from initial setup to advanced use cases.

In addition to online resources, we offer a suite of services to ensure your Ceramic PCB Board operates at peak performance. This includes troubleshooting assistance to help diagnose and resolve any issues you may encounter. Our dedicated team of technical experts is committed to providing timely and effective solutions to keep your operations running smoothly.

We also provide guidance on best practices for installation, maintenance, and handling of the Ceramic PCB Board to maximize its lifespan and reliability. For ongoing support, we offer updates and upgrades to ensure your product stays current with the latest technological advancements and industry standards.

Please note that while we strive to provide comprehensive support, our services do not include on-site assistance. However, our remote support is thorough and will be sufficient for most concerns and inquiries regarding the Ceramic PCB Board.

For any additional questions or specialized support needs, our customer service team is available to assist you. We are dedicated to ensuring you have all the necessary resources to effectively integrate and utilize your Ceramic PCB Board in your projects and products.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!