Product Description:

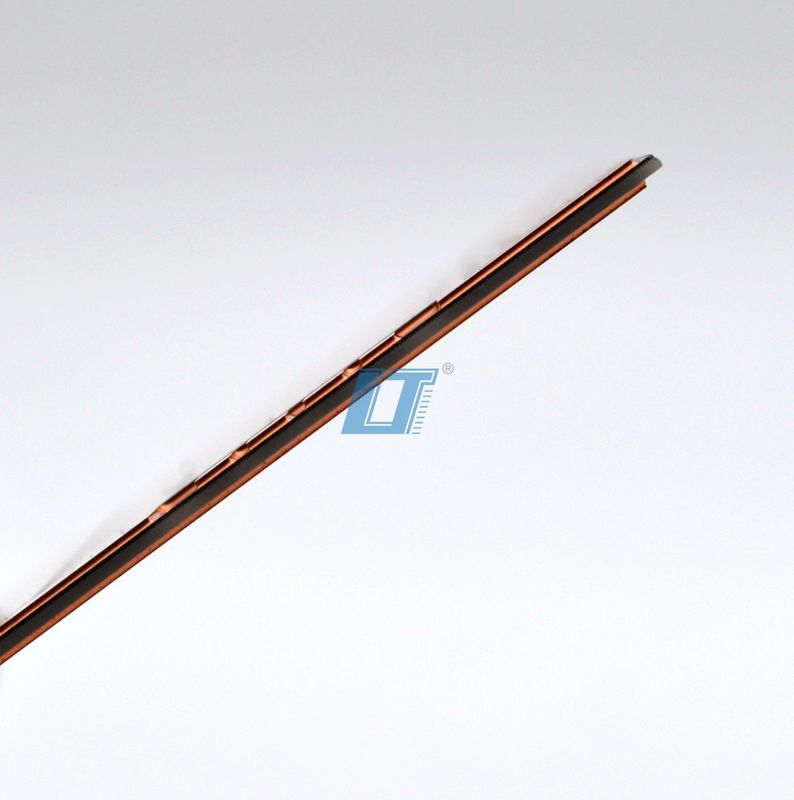

The Immersion Gold Ceramic PCB Board, specifically designed to meet the high standards of today's electronics industry, is a remarkable feat of engineering combining durability with high-performance capabilities. This PCB is meticulously crafted using Al2O3 Ceramic PCBs technology, which provides exceptional thermal conductivity and electrical insulation, making it an ideal choice for applications that require robust environmental resistance and high operational temperatures.

With surface technics that include Electroless Nickel Immersion Gold (ENIG) and nickel-palladium gold (GLOD), the Ceramic Printed Circuit Board boasts a surface finish that not only enhances the solderability of the board but also provides a level of protection against corrosion. The ENIG finish ensures a flat surface which is vital for the mounting of precision components, while the nickel-palladium gold layer adds a touch of excellence in terms of durability and connectivity.

Our Ceramic Substrate PCB is tailored to meet the specific needs of our clients, offering a one-stop service that includes Original Equipment Manufacturer (OEM) support and Design For Manufacturability (DFM) analysis. This comprehensive approach ensures that the final product is not only of high quality but also optimized for manufacturing efficiency and cost-effectiveness. The one-stop service simplifies the process for clients, providing them with a hassle-free experience from design to delivery.

The PCB size of this particular model stands at a compact 22mm*19mm, making it incredibly versatile for a range of applications while still offering the high-performance characteristics of larger boards. The small footprint allows for greater freedom in device design, enabling innovation and creativity in the development of new electronics.

Available in configurations ranging from 1 to 8 layers, the versatility of the Immersion Gold Ceramic PCB Board is unparalleled. Each layer is carefully constructed to ensure signal integrity and mechanical stability, providing the backbone for complex circuits that require multiple layers for signal routing and power distribution. The multi-layer capability also allows for the incorporation of advanced features such as impedance control, embedded capacitors, or resistors, further enhancing the functionality of the board.

Al2O3 Ceramic PCBs are renowned for their high dielectric strength and excellent heat dissipation properties. This makes them particularly suitable for high-power LED applications, power converters, and other high-temperature environments where traditional PCB materials might fail. The use of ceramic material also contributes to a significant reduction in thermal expansion issues, which can lead to improved reliability and longer product life cycles.

The Ceramic Substrate PCB is constructed with precision and attention to detail, ensuring that each board meets the exacting specifications required for high-performance applications. The use of high-quality materials, combined with state-of-the-art manufacturing processes, results in a PCB that is not only efficient in its function but also robust against physical and thermal stresses.

In conclusion, the Immersion Gold Ceramic PCB Board is a testament to the advancements in PCB technology, offering a combination of high thermal conductivity, excellent electrical insulation, and superior mechanical properties. With its ENIG and nickel-palladium GLOD surface technics, one-stop OEM and DFM services, compact size, and multi-layer capabilities, it stands as a prime choice for designers and engineers looking for a reliable and efficient solution in the realm of Ceramic Printed Circuit Boards.

Features:

- Product Name: Ceramic PCB Board

- Thermal Conductivity: 170 W/mK

- Operating Temperature: -50°C To 150°C

- Surface Technics: ENIG, nickel-palladium GLOD

- Min Line Width/Spacing: 0.1mm

- Pcb Size: 22mm*19mm

- Keywords:

- Ceramic Board with Copper Clad Laminate

- Ceramic Copper Clad PCB

- Ceramic Printed Circuit Board

Technical Parameters:

| Parameter |

Specification |

| Surface Technics |

ENIG, nickel-palladium GLOD |

| Min Line Width/Spacing |

0.1mm |

| Pcb Name |

Immersion Gold Ceramic PCB Board |

| Layers |

1-8 Layers |

| Service |

One-stop Service / OEM, DFM |

| Pcb Size |

22mm*19mm |

| Product Type |

PCB&PCBA OEM, DFM |

| Surface Finished |

Immersion Gold, nickel-palladium GLOD |

| Thermal Conductivity |

170 W/mK |

| Dielectric Constant |

6.0-10.0 |

Applications:

The Ceramic PCB Board, with its exceptional attributes, is a specialized product that finds its application in a multitude of scenarios, particularly where PCB&PCBAOEM and DFM (Design for Manufacturability) are essential. This type of PCB, fashioned out of a ceramic substrate, offers a robust platform for electronic components, ensuring reliability and performance in various applications.

One of the standout features of the Ceramic PCB Board is its surface finish. With an Immersion Gold and nickel-palladium GLOD finish, the product not only exemplifies excellent electrical conductivity but also provides a surface that is less prone to oxidation. This ensures longevity and consistent performance, making it an ideal choice for high-reliability electronics.

The remarkable thermal conductivity of 170 W/mK makes the Ceramic PCB Board a pillar of Ceramic Thermal Management PCB technology. This feature is particularly crucial in high-power applications where effective heat dissipation is imperative. The use of ceramic as a substrate material provides superior thermal management compared to traditional FR4 PCBs, making it an optimal solution for LED lighting systems, power converters, and high-speed electronics where thermal efficiency is a critical factor.

Precision is key in modern electronics, and the Ceramic PCB Board does not disappoint with its minimum line width and spacing of 0.1mm. This precision allows for high-density component placement, which is quintessential for today's compact electronic devices. The PCB Size of 22mm*19mm is also indicative of its suitability for applications where space is at a premium, such as in wearable technologies, medical devices, and aerospace electronics.

Furthermore, the Ceramic Hybrid PCB design integrates the best of both worlds by combining ceramic and traditional PCB materials, offering enhanced performance for applications that require the high-frequency operation. This hybrid approach is beneficial in telecommunications equipment, advanced sensors, and automotive electronics, where the integration of multiple technologies is necessary for optimal functionality.

In summary, the Ceramic Substrate PCB is a versatile product that excels in scenarios demanding high thermal performance, precise component placement, and superior surface finish. Its use extends across various industries, encompassing everything from consumer electronics to specialized industrial equipment, solidifying its role as a pivotal component in the advancement of electronic technology.

Customization:

We provide comprehensive Product Customization Services for Ceramic PCB Board products, ensuring a one-stop service experience tailored to your unique requirements. Our expertise in OEM and DFM practices allows us to deliver high-quality Ceramic Substrate PCBs that meet your specific needs.

With a variety of customization options, we can create Ceramic Hybrid PCBs with a sleek black solder mask colour that not only looks professional but also provides excellent contrast for easy inspection.

Whether you need a simple single-layer board or a complex 8-layer design, our services cover 1-8 Layers for your Ceramic Substrate PCB, offering versatility for a wide range of applications.

The PCB size can be precisely tailored to fit your product, with a standard dimension of 22mm*19mm. However, we can accommodate a range of sizes from 2mm up to 200mm, ensuring that your Ceramic Hybrid PCB is the perfect fit for your device.

Support and Services:

Our Ceramic PCB Board is designed to provide outstanding performance and reliability for a wide range of applications. To ensure you get the most out of your product, we offer a comprehensive suite of technical support and services.

Product Installation Guidance: Our team can provide you with step-by-step instructions to ensure your Ceramic PCB Board is installed correctly for optimal functionality.

Technical Consultation: If you have any questions or need advice regarding the integration of the Ceramic PCB Board into your system, our technical experts are on hand to assist you.

Troubleshooting Assistance: In the unlikely event that you encounter an issue with your Ceramic PCB Board, we offer troubleshooting support to help diagnose and resolve problems quickly and efficiently.

Firmware Updates: To keep your Ceramic PCB Board performing at its best, we provide timely firmware updates that enhance its functionality and add new features.

Repair Services: Should your Ceramic PCB Board require repairs, our skilled technicians are equipped to handle all levels of service, from minor fixes to major overhauls, ensuring a quick turnaround time.

Product Training: We offer training sessions to help you and your team understand the full capabilities of the Ceramic PCB Board and how to utilize it to its fullest potential.

End-of-Life Management: When it's time to upgrade or dispose of your Ceramic PCB Board, we can provide guidance on recycling and proper disposal in accordance with environmental regulations.

Our commitment to excellence is reflected in our support services, and we are dedicated to providing you with the assistance you need to ensure your Ceramic PCB Board continues to meet your needs effectively and efficiently.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!