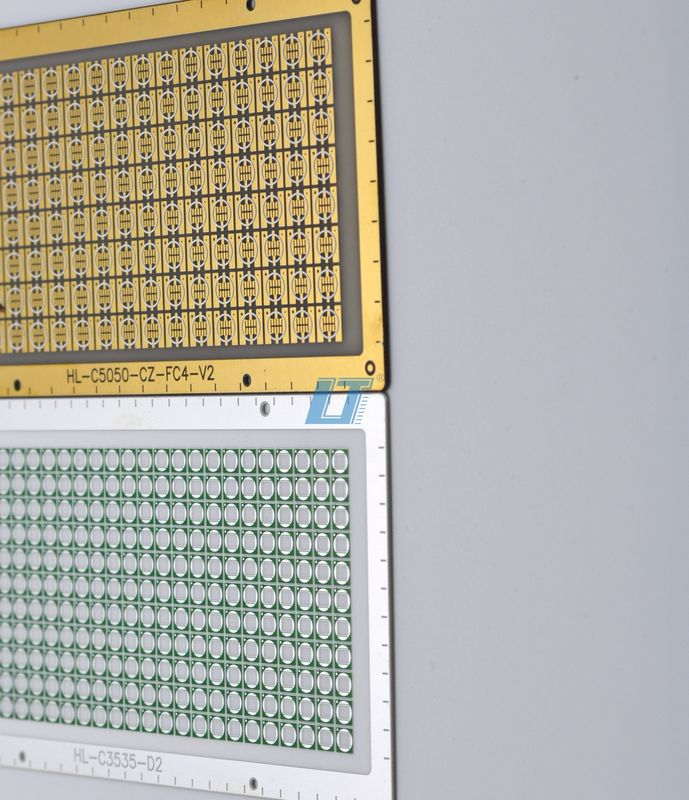

Advanced Ceramic PCB Board with Thermal Conductivity Immersion Gold Surface Finish Al2O3

Product Description:

The Ceramic PCB Board is a state-of-the-art printed circuit board (PCB) that stands at the forefront of modern electronics due to its exceptional thermal management capabilities and robust construction. This cutting-edge product is designed to meet the high demands of various applications, including but not limited to, high-frequency circuits, LED technology, and power electronics. The Ceramic PCB Board integrates advanced surface technics, such as Electroless Nickel Immersion Gold (ENIG) and nickel-palladium gold (GLOD), ensuring excellent surface finish and reliability.

One of the most notable features of the Ceramic PCB Board is its exceptional dielectric constant, which ranges from 6.0 to 10.0. This property makes it an ideal substrate for high-performance electronics that require stable and efficient signal propagation. The dielectric constant is a critical factor in determining the speed at which an electronic signal travels through the PCB, and with a higher dielectric constant, the Ceramic PCB Board is well-suited for high-speed applications.

In addition to its impressive dielectric properties, the Ceramic PCB Board boasts a surface finished with Immersion Gold and nickel-palladium GLOD. This surface finish not only provides a sleek and professional appearance but also offers superior conductivity and protection against oxidation. The Immersion Gold finish ensures a flat surface that is crucial for fine-pitch components, while the nickel-palladium GLOD provides a robust barrier layer that enhances the board's lifespan and performance.

The Ceramic PCB Board is engineered to provide a comprehensive one-stop service, catering to OEM and DFM (Design for Manufacturing) requirements. This service is tailored to streamline the manufacturing process and reduce time-to-market for products that incorporate the PCB. The one-stop service includes everything from design and prototyping to production and testing, making it an ideal choice for businesses looking to outsource their PCB needs to a reliable and experienced provider.

Available in configurations ranging from 1 to 8 layers, the Ceramic PCB Board offers flexibility in design and functionality. Its multilayer capability allows for complex circuits and higher component density, which is critical for sophisticated electronic devices. The ability to customize the number of layers according to specific project requirements makes the Ceramic PCB Board a versatile solution for a wide range of applications.

The Ceramic PCB Board is renowned for its Ceramic Thermal Management PCB capabilities, which are essential for high-power and high-temperature operations. Ceramic substrates are known for their high thermal conductivity, and the Ceramic PCB Board utilizes this feature to dissipate heat efficiently, thereby maintaining optimal performance and preventing overheating. High thermal conductivity Ceramic PCBs are crucial in applications where thermal management is a core concern, such as in LED lighting systems and power converters.

Furthermore, the board employs DBC (Direct Bond Copper), DPC (Direct Plated Copper), LTCC (Low-Temperature Co-fired Ceramic), and HTCC (High-Temperature Co-fired Ceramic) technologies. DBC and DPC are outstanding for their ability to handle high current loads and provide excellent thermal conductivity. On the other hand, LTCC and HTCC are techniques used to create multilayer ceramic PCBs with fine line resolution, which are suitable for high-density packaging and provide high levels of mechanical and thermal stability.

In conclusion, the Ceramic PCB Board is an innovative and reliable solution for any industry requiring advanced PCBs with superior thermal performance, high dielectric constant, and versatile layer configurations. With its robust surface technics, one-stop service, and ability to incorporate various advanced technologies like DBC, DPC, LTCC, and HTCC, it represents a top-tier option for designers and manufacturers seeking exceptional quality and performance in their electronic components.

Features:

- Product Name: Ceramic PCB Board

- Solder Mask Colour: Black

- Product Type: PCB&PCBAOEM,DFM

- Size: 2mm~200mm

- Service: One-stop Service / OEM,DFM

- Surface Finished: Immersion Gold, nickel-palladium GLOD

- Feature: Ceramic High Temperature PCB

- Conductivity: 170W/m·K ALN Ceramic PCBs

- Base Material: Ceramic Substrate PCB

Technical Parameters:

| Attribute |

Value |

| Pcb Name |

Immersion Gold Ceramic PCB Board |

| Product Type |

PCB&PCBAOEM, DFM |

| Min Line Width/Spacing |

0.1mm |

| Surface Technics |

ENIG, nickel-palladium GOLD |

| Layers |

1-8 Layers |

| Material |

Al2O3, ALN |

| Service |

One-stop Service / OEM, DFM |

| Operating Temperature |

-50°C To 150°C |

| Solder Mask Colour |

Black |

| Surface Finished |

Immersion Gold, nickel-palladium GOLD |

Applications:

The Ceramic PCB Board, featuring Copper Clad Laminate technology, is a high-performance solution designed to meet the diverse needs of modern electronics. This board is ideal for applications where extreme temperatures are a concern, as it operates effectively in a wide temperature range from -50°C to 150°C. With its robust service offerings, including one-stop service and OEM, as well as Design for Manufacturability (DFM) support, the Ceramic PCB Board is a versatile option for various application occasions and scenarios.

One of the primary application scenarios for the Ceramic PCB Board is in high-power devices. The board's excellent thermal conductivity makes it suitable for power converters, solid-state relays, and LED applications where heat dissipation is critical. The black solder mask not only provides a distinctive appearance but also enhances heat radiation, ensuring the longevity and reliability of the components mounted on it.

Moreover, the Ceramic PCB Board is an excellent choice for the aerospace and automotive industries, where devices often face extreme temperature fluctuations. Utilizing technologies such as Direct Bonded Copper (DBC) and Direct Plated Copper (DPC), the board guarantees high mechanical strength and superior electrical insulation, necessary for the rigorous demands of these industries.

In the field of telecommunications, the Ceramic PCB Board serves as a backbone for high-frequency equipment. With a dielectric constant ranging from 6.0-10.0, the board is engineered for minimal signal loss, thus ensuring high-speed signal transmission. The compact size options, ranging from 2mm to 200mm, allow for integration into various device form factors, from small sensors to larger communication modules.

Additionally, the Ceramic PCB Board is well-suited for medical devices, especially those requiring high-precision and stable performance. Advanced ceramics technologies like Low Temperature Co-fired Ceramic (LTCC) and High-Temperature Co-fired Ceramic (HTCC) are employed to cater to the stringent standards of the medical industry, including devices like implantable gadgets and diagnostic equipment.

In conclusion, the Ceramic PCB Board with its range of advanced features and technologies such as DBC, DPC, LTCC, and HTCC, is not only a testament to modern engineering but also a flexible solution for a multitude of high-performance applications. Whether it's for automotive, aerospace, telecommunication, medical, or high-power electronics, this ceramic board stands as a reliable platform for innovation and technological advancement.

Customization:

Our Ceramic Printed Circuit Board customization services cater to a variety of specifications to meet your unique requirements. With a minimum line width/spacing of 0.1mm, our boards are designed for precision and high-density applications. The thermal conductivity is exceptional, rated at 170 W/mK, ensuring efficient heat dissipation for high-power and high-temperature operations.

Designed to withstand extreme conditions, our Ceramic PCBs operate comfortably within a temperature range of -50°C to 150°C, making them suitable for Ceramic High Temperature PCB applications. Furthermore, the dielectric constant of our boards lies between 6.0-10.0, accommodating a range of electrical properties for your circuit design needs.

We offer a selection of materials, including Al2O3 and ALN, to match the performance and thermal management requirements of your project. Whether you’re looking for DBC (Direct Bond Copper) or DPC (Direct Plated Copper) technologies, or the advanced LTCC (Low Temperature Co-fired Ceramic) and HTCC (High Temperature Co-fired Ceramic) processes, we have the capabilities to deliver high-quality, customized ceramic PCB solutions.

Support and Services:

Our Ceramic PCB Board product is supported by a comprehensive technical support and service package designed to provide you with the assistance and guidance you need to maximize the performance and reliability of your product. Our services include:

Technical Assistance: Our team of experts is available to provide you with answers to your technical questions, troubleshooting tips, and advice on best practices for using and maintaining your Ceramic PCB Board.

Product Documentation: We offer a complete set of documentation including detailed product specifications, installation guides, and user manuals to help you understand the features and functionalities of the Ceramic PCB Board.

Firmware and Software Updates: To ensure your Ceramic PCB Board remains up-to-date and secure, we provide regular firmware and software updates. These updates are designed to enhance the product's capabilities, improve performance, and address any known issues.

Service and Maintenance: Our service programs are tailored to keep your Ceramic PCB Board in optimal condition. We offer maintenance services that can be scheduled at your convenience to minimize downtime and ensure your operations run smoothly.

Training: We offer training sessions for individuals and groups to help you understand how to effectively use the Ceramic PCB Board. Training can be customized to your specific needs and can be conducted onsite or online, depending on your preference.

Warranty Support: Our Ceramic PCB Board comes with a standard warranty that covers defects in materials and workmanship. For additional peace of mind, we offer extended warranty options to provide you with longer coverage.

Quality Assurance: Quality is our top priority. Our Ceramic PCB Boards undergo rigorous testing and quality control procedures to ensure that you receive a product that meets the highest standards of performance and reliability.

We are committed to providing you with exceptional support and services for our Ceramic PCB Board product. If you have any questions or require assistance, please do not hesitate to reach out to our technical support team for expert help.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!