Product Description:

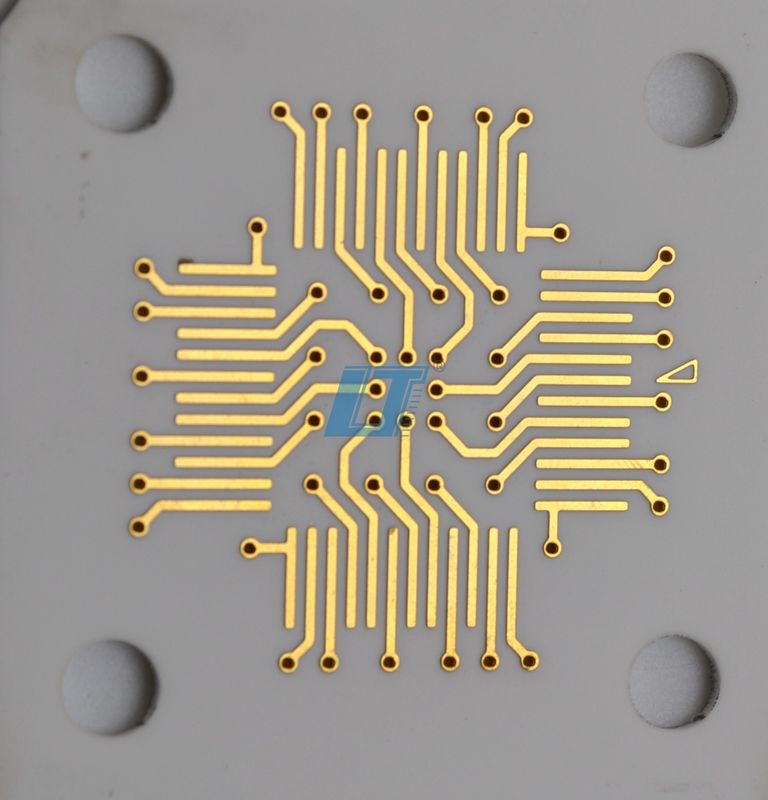

The Immersion Gold Ceramic PCB Board represents a significant leap in PCB technology, combining the robustness of ceramic materials with advanced surface technics to deliver a product that stands out in the realm of electronics manufacturing. With a PCB size of 22mm*19mm, this product is designed to fit a variety of applications requiring compact and efficient circuitry. The surface of the PCB is finished with ENIG (Electroless Nickel Immersion Gold), which is complemented by a nickel-palladium gold (GLOD) layer, ensuring excellent conductivity and a long-lasting, corrosion-resistant surface.

As a premium product type in the PCB&PCBAOEM,DFM category, this ceramic PCB board boasts superior thermal conductivity and electrical insulation, thanks to its advanced ceramic base material. One of the most significant advantages of using Al2O3 (Aluminum Oxide) Ceramic PCBs is their ability to withstand high temperatures and harsh environments, making them an ideal choice for high-power circuits, LED lighting, and automotive applications.

The Immersion Gold Ceramic PCB Board employs various ceramic PCB technologies such as DBC (Direct Bond Copper), DPC (Direct Plated Copper), LTCC (Low Temperature Co-fired Ceramic), and HTCC (High Temperature Co-fired Ceramic). DBC and DPC are both well-suited for high power applications due to their excellent thermal management properties. LTCC and HTCC, on the other hand, offer multi-layer capabilities and are perfect for complex circuits that require a high level of integration and performance.

One of the most striking features of this Ceramic PCB Board is its meticulous attention to detail when it comes to the min line width/spacing, which is an impressive 0.1mm. This allows for high-density circuit designs, enabling more components to be placed on the board and ultimately leading to miniaturization of the end product without compromising performance.

The Ceramic Board with Copper Clad Laminate incorporates a thin layer of copper, which is directly bonded to the ceramic substrate, providing excellent electrical performance and superior heat dissipation. The use of copper clad laminate is particularly beneficial in applications that require a high degree of thermal management and stability, such as power converters, RF amplifiers, and high-speed digital circuitry.

In summary, the Immersion Gold Ceramic PCB Board is a state-of-the-art solution for various applications that demand high reliability, great thermal performance, and precise signal integrity. Whether for industrial, automotive, or consumer electronics, this ceramic PCB board delivers unparalleled performance, thanks to its cutting-edge construction and meticulous manufacturing process. Its robustness, coupled with the advanced surface technics of ENIG and nickel-palladium GLOD, ensures that it meets the stringent requirements of modern electronic devices, providing engineers and designers with a versatile platform for innovation and development.

Features:

- Product Name: Ceramic PCB Board

- Thermal Conductivity: 170 W/mK

- Solder Mask Colour: Black

- Size: 2mm~200mm

- Surface Finished: Immersion Gold, nickel-palladium GLOD

- Min Line Width/Spacing: 0.1mm

- Ceramic Insulated Metal Substrate

- Ceramic Board with Copper Clad Laminate

- Ceramic High Temperature PCB

Technical Parameters:

| Parameter |

Specification |

| Pcb Name |

Immersion Gold Ceramic PCB Board |

| Thermal Conductivity |

170 W/mK |

| Size |

2mm~200mm |

| Layers |

1-8 Layers |

| Operating Temperature |

-50°C To 150°C |

| Service |

One-stop Service / OEM,DFM |

| Dielectric Constant |

6.0-10.0 |

| Min Line Width/Spacing |

0.1mm |

| Solder Mask Colour |

Black |

| Surface Technics |

ENIG, nickel-palladium GLOD |

Applications:

The Immersion Gold Ceramic PCB Board, with its 1-8 layers configuration, is a premium choice for applications demanding high thermal conductivity and excellent electrical insulation. The PCB size of 22mm*19mm makes it a versatile component for a wide range of electronic devices. The minimum line width and spacing of 0.1mm ensure high-density interconnects for complex circuit designs. Constructed from high-quality materials such as Al2O3 and ALN, this PCB is engineered to meet the rigorous demands of advanced electronic applications.

One of the key applications of the Immersion Gold Ceramic PCB Board lies in its use as a Ceramic Dielectric PCB. The exceptional dielectric properties of ceramic materials make this PCB an ideal choice for RF and microwave circuits where low signal loss and high frequency performance are critical. This makes it suitable for telecommunications equipment, radar systems, and satellite communication systems where signal integrity cannot be compromised.

In addition to its use in high-frequency applications, the ALN Ceramic PCBs are particularly advantageous in high-temperature environments. Aluminum Nitride (ALN) has superior thermal conductivity, which is essential for heat dissipation in power electronics. Thus, this type of PCB is often found in LED lighting systems, high-power transistors, and semiconductor refrigeration devices. Its ability to handle thermal stresses ensures reliability and longevity in such applications.

Furthermore, the Immersion Gold Ceramic PCB Board is a perfect candidate for medical devices. The biocompatibility of ceramic materials, along with the precision offered by the board's minuscule line width and spacing, allows for the creation of intricate devices such as sensors and imaging equipment. The ceramic dielectric also provides excellent isolation, which is crucial for sensitive measurements and patient safety.

Lastly, in the field of aerospace and defense, the robustness of Ceramic Dielectric PCBs is particularly valued. These boards can withstand extreme conditions such as rapid temperature changes, high levels of vibration, and exposure to chemicals or radiation. The small size of the PCB also aids in the miniaturization of devices, which is a significant factor in aerospace applications where space and weight are at a premium.

Overall, the Immersion Gold Ceramic PCB Board is a high-performance solution for a multitude of scenarios where reliability, precision, and efficiency are paramount. Its adaptability to various layers, coupled with the choice of Al2O3 and ALN materials, positions it as a preferred choice for cutting-edge electronic applications across various industries.

Customization:

Our Ceramic PCB Board product offers a range of customization services to meet the specific needs of your project. With advanced Surface Technics options such as ENIG (Electroless Nickel Immersion Gold), nickel-palladium, and GLOD (Gold Layer Over Dielectric), we ensure high-quality finishes for superior performance. Our Ceramic Board with Copper Clad Laminate boasts an impressive Thermal Conductivity of 170 W/mK, making it an ideal choice for applications requiring efficient heat dissipation.

We cater to a variety of sizes, ranging from 2mm to 200mm, with a standard Pcb Size of 22mm*19mm to fit your design specifications. Whether you are looking for a Ceramic Hybrid PCB with multiple functionality or a simple Ceramic Printed Circuit Board, we can accommodate 1-8 Layers to suit the complexity of your electronic assembly. Customize your Ceramic PCB with us and leverage the advantages of high-quality materials and precision engineering for your electronic projects.

Support and Services:

Our Ceramic PCB Board product comes with a comprehensive suite of technical support and services to ensure your satisfaction and the optimal performance of the product. Our technical support includes a detailed user manual with instructions for proper installation, use, and maintenance of the PCB. Additionally, we offer an extensive FAQ section on our website where you can find answers to common questions and troubleshoot minor issues.

For more complex technical inquiries or issues, we have a dedicated team of experienced engineers who can provide guidance and support. They are well-versed in all aspects of Ceramic PCB technology and can assist you with design considerations, performance optimization, and other technical challenges you may encounter.

We also provide services for custom design solutions tailored to your specific needs. Our team can help with the design, prototyping, and testing of custom Ceramic PCBs to ensure they meet your application requirements.

Additionally, we offer a warranty for our Ceramic PCB Boards that covers defects in materials and workmanship. During the warranty period, we will repair or replace any defective boards at no additional cost to the customer.

We are committed to continuous improvement and customer feedback is invaluable to us. We encourage you to contact our support team with any suggestions or comments you have about our product or services.

Our goal is to provide you with the highest level of support to ensure that our Ceramic PCB Board exceeds your expectations and contributes to the success of your projects.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!