Product Description:

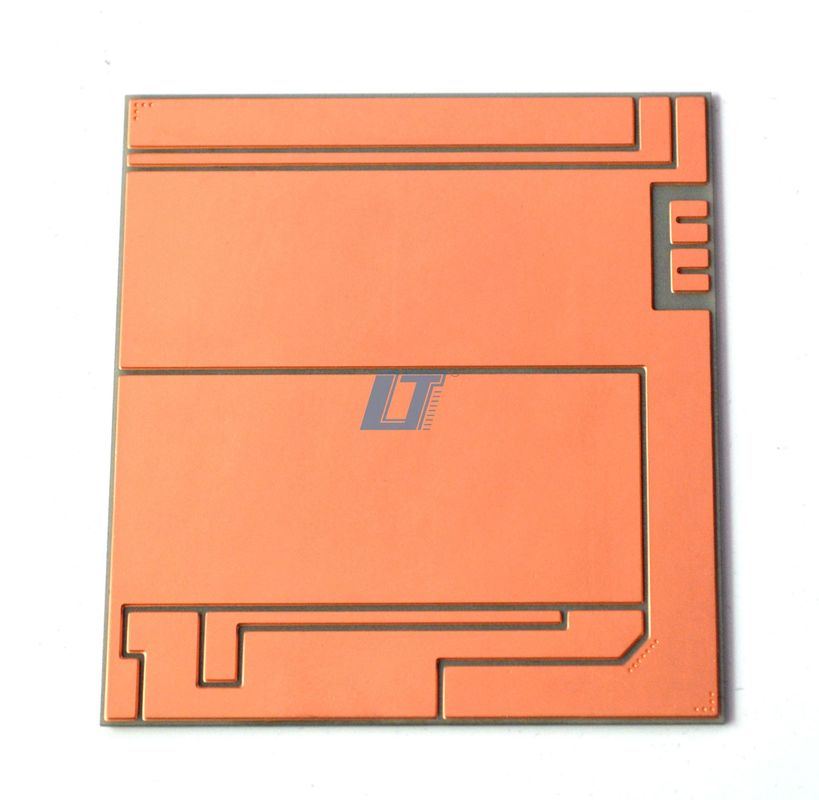

The Immersion Gold Ceramic PCB Board represents a significant advancement in PCB&PCBAOEM, DFM technologies, offering cutting-edge solutions to meet the high demands of modern electronics. This product is meticulously crafted to serve a wide range of applications, ranging from high-power circuits to sensitive RF equipment, where material stability under heat and precise signal integrity are paramount.

At the core of the Immersion Gold Ceramic PCB Board's exceptional performance is the use of Ceramic Board with Copper Clad Laminate. This material choice not only ensures high thermal conductivity but also provides excellent electrical insulation, making it ideal for high-temperature applications. The Ceramic High Temperature PCB is designed to withstand extreme environmental conditions, thus ensuring reliability and longevity of the electronic components mounted on it.

The board's surface technics feature an Electroless Nickel Immersion Gold (ENIG) coating, which is widely recognized for its excellent surface planarity, solderability, and resistance to oxidation. The nickel-palladium GLOD is an additional layer that reinforces the PCB's robustness against harsh conditions, further enhancing its durability. The combination of these technics results in a high-quality surface finish that not only protects the board but also optimizes the performance of the final product.

With a versatile size range from 2mm to 200mm, the Immersion Gold Ceramic PCB Board can be tailored to fit specific requirements, ensuring compatibility with a broad spectrum of devices and applications. This adaptability makes it an ideal substrate for both prototypes and mass-produced electronics, providing designers with a reliable base for their innovative circuits.

The surface finish of the Immersion Gold, complemented by the nickel-palladium GLOD, not only adds a layer of protection against corrosion but also significantly improves the board's wettability. This ensures a strong bond between the PCB and the solder, which is crucial for creating durable and long-lasting electronic assemblies. The Immersion Gold surface finish also provides a flat and uniform surface which is conducive to fine-pitch components, facilitating the assembly of densely populated boards.

Ceramic Copper Clad PCBs are gaining popularity due to their superior thermal management capabilities. The Immersion Gold Ceramic PCB Board is no exception, as it effectively dissipates heat away from critical components, ensuring that the device operates within safe temperature limits. This is especially important for high-power electronics where overheating can lead to performance degradation or even failure.

In summary, the Immersion Gold Ceramic PCB Board is designed to meet the highest standards of quality and performance. Its use of Ceramic Board with Copper Clad Laminate ensures excellent thermal and electrical characteristics, while the ENIG and nickel-palladium GLOD surface technics provide a robust and reliable finish. Available in a wide range of sizes and with a surface finish designed for optimal electrical performance, this Ceramic High Temperature PCB is an ideal choice for anyone looking to enhance the durability and functionality of their electronic products.

Features:

- Product Name: Ceramic PCB Board

- Solder Mask Colour: Black

- Thermal Conductivity: 170 W/mK

- Size: 2mm~200mm

- Operating Temperature: -50°C To 150°C

- Min Line Width/Spacing: 0.1mm

- ALN Ceramic PCBs

- Ceramic Copper Clad PCB

- 170W/m·K ALN Ceramic PCBs

Technical Parameters:

| Technical Parameter |

Specification |

| Service |

One-stop Service / OEM,DFM |

| Operating Temperature |

-50°C To 150°C |

| Solder Mask Colour |

Black |

| Dielectric Constant |

6.0-10.0 |

| Product Type |

PCB&PCBAOEM,DFM |

| Pcb Name |

Immersion Gold Ceramic PCB Board |

| Thermal Conductivity |

170 W/mK |

| Min Line Width/Spacing |

0.1mm |

| Layers |

1-8 Layers |

| Surface Technics |

ENIG, nickel-palladium GLOD |

Applications:

The Immersion Gold Ceramic PCB Board, known for its exceptional characteristics, is a product tailored for a wide range of applications and scenarios. This PCB is designed with 1-8 layers and a compact size of 22mm*19mm, making it suitable for diverse electronic requirements. The board offers a one-stop service that includes Original Equipment Manufacturer (OEM) and Design for Manufacturability (DFM) options, ensuring that the end product is both efficiently designed and easy to manufacture while being tailored to customer specifications.

High thermal conductivity Ceramic PCBs such as the Immersion Gold Ceramic PCB Board are ideal for applications where thermal management is critical. The high thermal conductivity feature allows for efficient heat dissipation, making these PCBs highly sought after in industries where electronic components are subjected to high temperatures. This makes them particularly suitable for use in LED lighting systems, automotive electronics, high power transistors, and laser technology where maintaining a certain temperature is crucial for performance and longevity.

One of the most significant advantages of the Immersion Gold Ceramic PCB Board is its robustness in terms of thermal performance. The Ceramic Insulated Metal Substrate used in this type of PCB provides an excellent foundation for high-power circuits and applications in harsh environments. The ceramic substrate acts as a superior electrical insulator while also conducting heat away from critical components, thereby reducing thermal stress and enhancing product reliability.

Given the high demand for electronics that can withstand demanding conditions, the Immersion Gold Ceramic PCB Board finds its applications in aerospace, defense, and telecommunication sectors. These sectors benefit from the board's ability to operate efficiently under extreme temperatures and environments, where traditional PCBs might fail. Furthermore, the immersion gold surface finish ensures excellent surface planarity and provides a reliable surface for fine-pitch components or complex IC packages, thereby enhancing signal integrity.

In the medical industry, High thermal conductivity Ceramic PCBs are used in high-frequency equipment and devices that require precise temperature control. The Immersion Gold Ceramic PCB Board, with its superior thermal properties, is an excellent choice for medical imaging devices, diagnostic equipment, and other sensitive instrumentation that demand consistent performance and reliability.

Lastly, the Immersion Gold Ceramic PCB Board is also perfectly suited for consumer electronics where space is at a premium and effective heat dissipation is necessary to prevent overheating. This includes high-performance computers, gaming systems, and portable electronic devices. The OEM and DFM services offered ensure that these boards are customized to fit the unique needs of each product, offering manufacturers the flexibility and quality they need to create cutting-edge electronic devices.

Customization:

We offer comprehensive Product Customization Services for our Immersion Gold Ceramic PCB Board , tailored to meet the needs of diverse applications. Our expertise in PCB&PCBAOEM,DFM ensures high-quality and reliable circuit boards that align with your specific requirements.

Our Ceramic Hybrid PCB leverages advanced technology for superior performance. With a thermal conductivity of 170 W/mK , it is designed to handle rigorous thermal demands, ensuring optimal operation from -50°C to 150°C . The robust solder mask colour in black not only adds a sleek finish but also provides additional protection.

We understand the importance of durability and efficiency in circuit design, which is why our ALN Ceramic PCBs are a popular choice for high-temperature applications. As a leading provider of Ceramic Printed Circuit Boards , we are committed to delivering products that exceed industry standards and your expectations.

Support and Services:

Our Ceramic PCB Board comes with comprehensive technical support and services designed to ensure the optimal performance and longevity of your product. Our support includes access to a range of resources and services, including:

Technical Documentation: We provide detailed technical documentation to help you understand the specifications and features of your Ceramic PCB Board. This includes material data sheets, user manuals, and installation guides.

Product Troubleshooting: If you encounter any issues with your Ceramic PCB Board, our team is ready to assist you with troubleshooting steps to identify and resolve the problem quickly and efficiently.

Firmware Updates: To keep your Ceramic PCB Board up-to-date with the latest features and security patches, we offer firmware updates that can be easily downloaded and installed.

Repair Services: In the event that your Ceramic PCB Board requires repair, we offer professional repair services to restore your product to its optimal condition. Our skilled technicians use only genuine parts for all repairs.

Technical Training: For customers looking to gain a deeper understanding of our Ceramic PCB Boards, we offer technical training sessions that cover product features, installation, and maintenance procedures.

We are committed to providing exceptional support to ensure that you can fully leverage the capabilities of your Ceramic PCB Board. Our team of experts is here to help you maximize the performance and reliability of your product throughout its lifecycle.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!