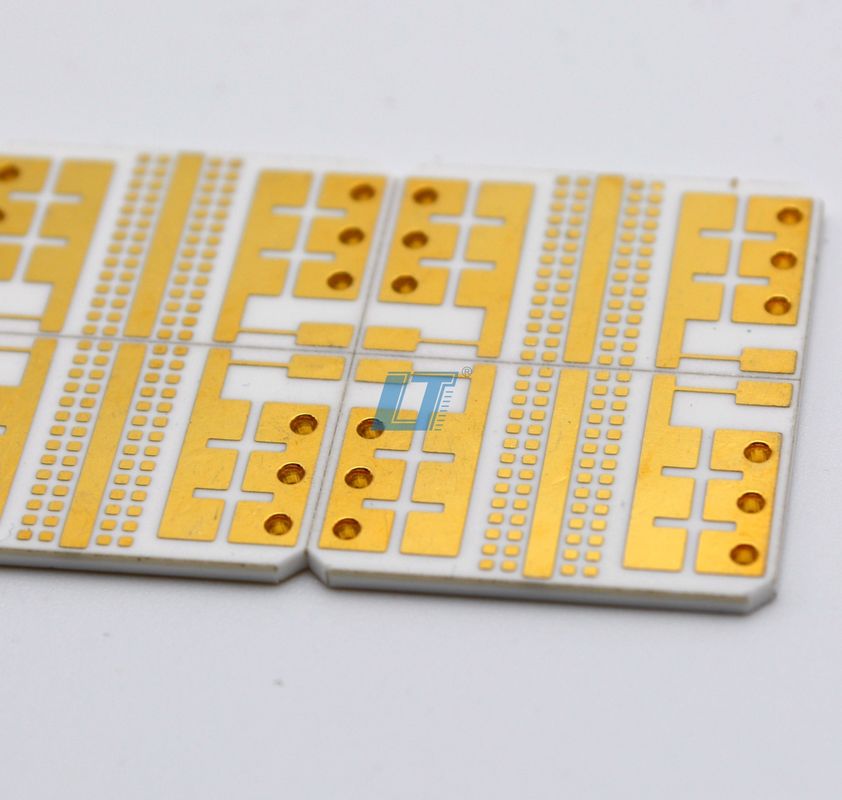

1-8 Layer Immersion Gold Ceramic PCB Board Al2O3/ALN Dielectric Constant for PCB/PCBAOEM

Product Description:

The Ceramic PCB Board is a high-performance platform designed for advanced electronic applications where robustness and high thermal management capabilities are essential. This product falls under the category of PCB&PCBAOEM, DFM, ensuring that it is not only a printed circuit board but also includes the option for Original Equipment Manufacturer services and Design for Manufacturability. This ensures that each board is tailored to meet the specific requirements of the customer's application, providing an optimized solution that can withstand demanding environments.

One of the standout features of the Ceramic PCB Board is its impressive operating temperature range of -50°C to 150°C. This wide range makes it suitable for use in extreme conditions, where traditional PCB materials might fail. Whether operating in the chilly confines of aerospace applications or the heated interior of automotive electronics, the Ceramic PCB Board maintains its structural integrity and electrical performance.

The board is available in configurations ranging from 1 to 8 layers, offering flexibility in its applications. With multiple layers, the board can accommodate more complex circuits, making it ideal for sophisticated electronic systems. The multilayer capability also allows for better optimization of space and the potential for a more compact overall design.

With a dielectric constant ranging from 6.0 to 10.0, the Ceramic PCB Board is well-suited for high-frequency applications. The dielectric constant is a measure of a material's ability to store electrical energy in an electric field. A higher dielectric constant indicates that the material can store more energy, making it an ideal choice for high-speed electronics where signal integrity is paramount.

Moreover, the Ceramic PCB Board boasts an exceptional thermal conductivity of 170 W/mK, which is significantly higher than that of traditional FR-4 PCBs. This high thermal conductivity is crucial for dissipating heat away from critical components, thereby minimizing the risk of thermal hotspots and improving the overall lifespan of the electronic device. It is particularly beneficial in power electronics, LED applications, and high-power transistors, where efficient thermal management is critical.

The Ceramic PCB Board employs various technologies, such as Direct Bonded Copper (DBC), Direct Plated Copper (DPC), Low-Temperature Co-fired Ceramic (LTCC), and High-Temperature Co-fired Ceramic (HTCC). These methods provide excellent adhesion between the ceramic substrate and the copper conductive layers, ensuring high reliability and performance. DBC and DPC are well-known for their ability to handle high current loads, while LTCC and HTCC are prized for their high-density packaging and robustness in extreme environments.

The combination of these technologies results in the Ceramic Dielectric PCB, a type of PCB that uses ceramic materials for its dielectric substrate. This gives the board superior electrical insulation properties, along with outstanding thermal stability. The Ceramic Copper Clad PCB, another variant, involves a ceramic base with copper cladding, which is ideal for applications requiring excellent electrical conductivity and heat dissipation.

In summary, the Ceramic PCB Board is an exceptional choice for applications that demand high thermal performance, stability across a wide range of temperatures, and the ability to withstand harsh environments. Its versatility in terms of layering, high dielectric constant, and superior thermal conductivity, coupled with the use of advanced DBC, DPC, LTCC, and HTCC technologies, make it an unparalleled solution for a wide range of high-demand electronic applications. The product's adherence to OEM and DFM principles further ensures that each board can be customized to meet the exact needs of the customer, providing a reliable and high-quality foundation for any electronic device.

Features:

- Product Name: Ceramic PCB Board

- Operating Temperature: -50°C To 150°C

- Product Type: PCB&PCBAOEM, DFM

- Surface Technics: ENIG, nickel-palladium GLOD

- Service: One-stop Service / OEM, DFM

- Dielectric Constant: 6.0-10.0

- Keywords: Ceramic High Temperature PCB

- Keywords: ALN Ceramic PCBs

- Keywords: Ceramic Dielectric PCB

Technical Parameters:

| Attribute |

Detail |

| Service |

One-stop Service / OEM,DFM |

| Material |

Al2O3,ALN |

| Pcb Name |

Immersion Gold Ceramic PCB Board |

| Operating Temperature |

-50°C To 150°C |

| Thermal Conductivity |

170 W/mK |

| Min Line Width/Spacing |

0.1mm |

| Surface Technics |

ENIG,nickel-palladium GLOD |

| Solder Mask Colour |

Black |

| Dielectric Constant |

6.0-10.0 |

| Layers |

1-8 Layers |

Applications:

The Immersion Gold Ceramic PCB Board, which features advanced surface technics such as Electroless Nickel Immersion Gold (ENIG) and nickel-palladium gold (GLOD), is an exceptional choice for applications requiring high reliability and endurance. With a minimum line width/spacing of 0.1mm, these ceramic printed circuit boards (PCBs) are designed to accommodate intricate circuit designs while maintaining high precision and performance.

Equipped with a remarkable thermal conductivity of 170 W/mK, the Al2O3 Ceramic PCBs are particularly suitable for scenarios where efficient heat dissipation is critical. This high thermal conductivity ensures that these boards can sustain optimal performance even under high temperature operating conditions, making them ideal for use in ceramic high temperature PCB applications.

The versatility of these PCBs, ranging from 1 to 8 layers, allows for their use in a wide array of electronic devices and systems. They can be deployed in LED lighting solutions, where managing heat is essential to preserve the lifespan and efficiency of the LEDs. In power electronics, such as high-power transistors and converters, the ceramic PCB’s ability to handle substantial thermal loads without performance degradation is invaluable.

Furthermore, aerospace and automotive industries benefit from the use of Immersion Gold Ceramic PCB Boards due to their resilience to extreme temperatures and conditions. These industries require components that can withstand the rigors of high-speed travel and fluctuations in environmental conditions without failure.

Medical devices also make extensive use of ceramic PCBs. The high thermal conductivity and reliability of the Immersion Gold Ceramic PCB Board make it a preferred choice for medical diagnostic equipment, where stable and precise temperature control is necessary for accurate readings and patient safety.

In summary, the Immersion Gold Ceramic PCB Board is a versatile and robust solution well-suited for a variety of demanding applications, including high temperature environments and scenarios that require precise thermal management and high-density circuit designs. Their ENIG and nickel-palladium gold surface technics further enhance their durability and connectivity, solidifying their position as a premium choice for advanced electronic applications.

Customization:

Our Ceramic Substrate PCB customization service offers a range of product attributes tailored to your specific needs. With a Dielectric Constant ranging from 6.0-10.0, our Ceramic Dielectric PCB ensures optimal electrical performance for your applications. Our Ceramic Printed Circuit Boards are designed to withstand Operating Temperatures from -50°C to 150°C, making them suitable for a variety of challenging environments.

We specialize in PCB&PCBA OEM and DFM solutions, providing you with a high-quality Ceramic PCB Board that meets your exact requirements. Our standard Pcb Size is 22mm*19mm, but we can customize dimensions to fit your unique specifications. Additionally, with a Thermal Conductivity of 170 W/mK, our Ceramic PCBs ensure efficient heat dissipation for your electronic components, enhancing their longevity and reliability.

Support and Services:

Our Ceramic PCB Board is a high-quality product designed to meet the stringent requirements of various electronic applications. We are committed to providing exceptional technical support and services to ensure the optimal performance of your Ceramic PCB Board. Our support includes:

Product Consultation: Our team of experts is available to provide advice on the best Ceramic PCB Board for your specific application, taking into account factors such as thermal conductivity, electrical requirements, and mechanical strength.

Technical Assistance: Should you encounter any issues or have questions regarding the functionality or integration of our Ceramic PCB Boards, our technical support team is on standby to provide you with the necessary guidance and troubleshooting tips.

Quality Assurance: All of our Ceramic PCB Boards undergo rigorous testing and quality checks to ensure they meet industry standards and our own high benchmarks for performance and reliability.

Documentation: We provide comprehensive documentation, including detailed specifications, installation guides, and maintenance procedures to help you make the most of your Ceramic PCB Board.

After-Sales Services: Our commitment to your satisfaction extends beyond the purchase. We offer after-sales support to address any concerns or questions that may arise during the lifetime of the product.

Our goal is to ensure that you have all the resources and support you need for a successful experience with our Ceramic PCB Board. We take pride in the quality of our products and services and look forward to assisting you.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!