Product Description:

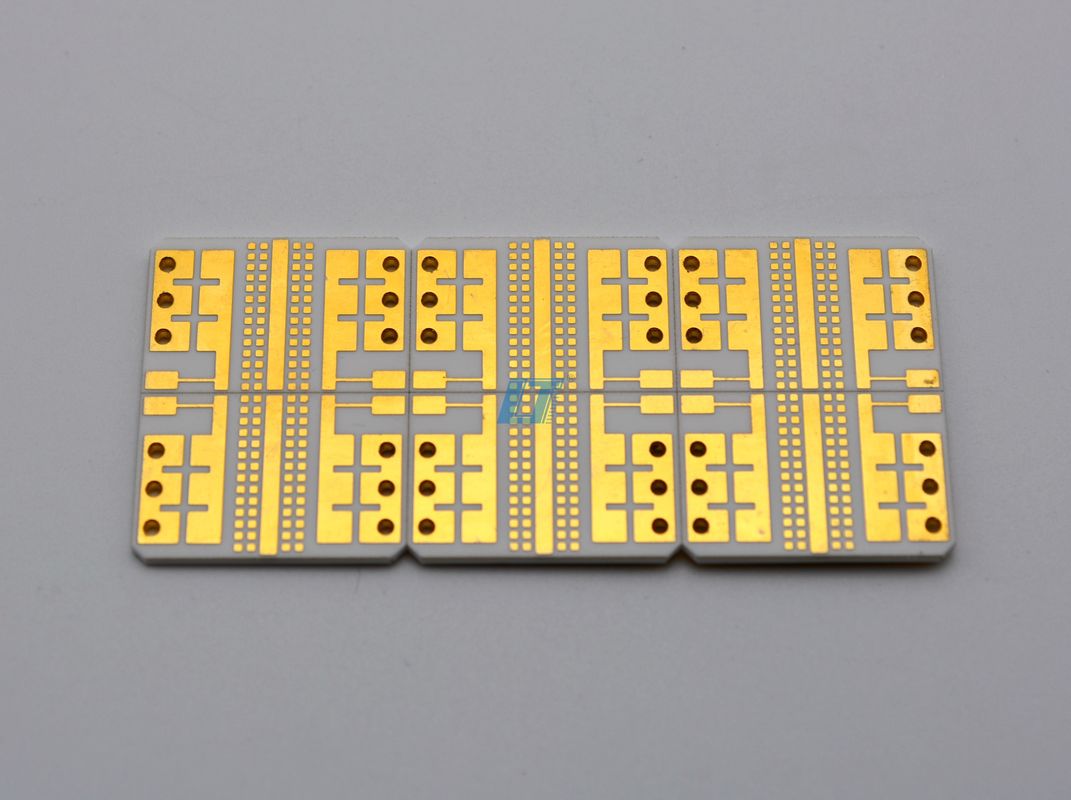

The Ceramic PCB Board is a state-of-the-art electronics component designed to meet the highest standards of efficiency, durability, and reliability in the most demanding applications. This product is a Ceramic Hybrid PCB, which means it combines the best of both worlds: the robustness and thermal management of ceramics with the versatility and convenience of traditional PCB technology. The board's dimensions are a compact 22mm by 19mm, making it suitable for a wide range of electronic devices where space is at a premium.

One of the most critical features of the Ceramic PCB Board is its material composition. It is crafted from high-quality ceramics such as Aluminum Oxide (Al2O3) and Aluminum Nitride (ALN). These materials are chosen for their exceptional properties, including high thermal conductivity, excellent electrical insulation, and resistance to chemical and mechanical wear. The Al2O3 offers a cost-effective solution with good performance, while the ALN variant provides even higher thermal conductivity for the most thermally challenging environments.

The PCB is characterized by a high dielectric constant, ranging from 6.0 to 10.0, which is indicative of its excellent ability to store and release electrical energy. This makes the Ceramic PCB Board an ideal platform for high-frequency applications where dielectric properties are crucial. It is also a perfect fit for LED technology, power electronics, and high-speed digital circuits, where the dielectric constant plays a significant role in the overall performance of the electronic system.

Another standout feature of this Ceramic PCB Board is its operating temperature range. The board is designed to function optimally in extreme conditions, from as low as -50°C to as high as 150°C. This vast temperature range ensures that the PCB can withstand the rigors of harsh environments, including automotive, aerospace, and industrial applications. Whether exposed to frigid or sweltering conditions, the Ceramic PCB Board maintains its integrity and performance.

In addition, the board comes with a high-quality solder mask in black. The black solder mask not only gives the board a sleek and professional appearance but also enhances its thermal properties. Black absorbs heat more efficiently, aiding in the rapid dissipation of heat from the components mounted on the board. This feature is particularly beneficial for high-power and LED applications, where managing heat is essential to the longevity and reliability of the electronic assembly.

As part of the Ceramic PCB Board's advanced design, it may incorporate different ceramic PCB technologies such as DBC (Direct Bond Copper), DPC (Direct Plated Copper), LTCC (Low Temperature Co-fired Ceramic), and HTCC (High Temperature Co-fired Ceramic). DBC and DPC are known for their excellent thermal management and are commonly used in power electronics, while LTCC and HTCC are suitable for complex, multi-layered PCB designs and are often employed in high-frequency applications.

The versatility of the Ceramic Dielectric PCB makes it a top choice for a diverse array of industries, including medical devices, telecommunications, military, and consumer electronics. Its robustness, coupled with superior thermal and electrical performance, ensures that any product equipped with the Ceramic PCB Board is set to benefit from increased reliability, enhanced performance, and prolonged operational life.

In conclusion, the Ceramic PCB Board embodies the perfect blend of modern PCB technology with the unparalleled properties of ceramic materials. It is an essential component for anyone looking to improve the performance and durability of their electronic products. With its compact size, high dielectric constant, expansive operating temperature range, and superior material composition, this PCB is a testament to the advancements in electronic component design and manufacturing.

Features:

- Product Name: Ceramic PCB Board

- Layers: 1-8 Layers

- Min Line Width/Spacing: 0.1mm

- Surface Technics: ENIG, nickel-palladium GLOD

- Thermal Conductivity: 170 W/mK

- Service: One-stop Service / OEM, DFM

- Product Type: Ceramic Substrate PCB

- Product Category: Ceramic Printed Circuit Board

- Special Feature: Ceramic High Temperature PCB

Technical Parameters:

| Product Type |

PCB&PCBAOEM,DFM |

| Material |

Al2O3,ALN |

| Surface Technics |

ENIG,nickel-palladium GOLD |

| Min Line Width/Spacing |

0.1mm |

| Service |

One-stop Service / OEM,DFM |

| Solder Mask Colour |

Black |

| Operating Temperature |

-50°C To 150°C |

| Dielectric Constant |

6.0-10.0 |

| Thermal Conductivity |

170 W/mK |

| Size |

2mm~200mm |

Applications:

The Ceramic PCB Board, specially designed for applications where high thermal conductivity and electrical insulation are paramount, comes in various sizes ranging from 2mm to 200mm. These boards are ideal for a multitude of occasions and scenarios, given their robust build and the flexibility offered by the one-stop service for OEM and DFM (Design for Manufacturability) support. The surface finish of Immersion Gold or nickel-palladium GLOD ensures a reliable and durable connection, vital for consistent performance in demanding environments.

One of the key application scenarios for High thermal conductivity Ceramic PCBs is in LED lighting systems. The superior thermal management capabilities of the ceramic substrate PCB allow for efficient heat dissipation, ensuring longevity and consistent operation of high-power LEDs. This makes them particularly suitable for automotive lighting, street lights, and high-brightness indoor lighting fixtures where reliability is crucial.

Moreover, ALN (Aluminum Nitride) Ceramic PCBs are extensively used in the electronics industry, especially in high-frequency circuits and RF applications. Their exceptional thermal performance coupled with minimal thermal expansion makes them ideal for use in sensitive electronics that require stable operation over a wide temperature range. Applications in telecommunications, aerospace, and defense industries often utilize ALN Ceramic PCBs for their stability and high-frequency performance.

Another scenario where these Ceramic PCB Boards are indispensable is within the medical field. Equipment such as scanners, X-ray machines, and other diagnostic tools benefit greatly from the ceramic PCB's ability to operate reliably under high-temperature conditions while ensuring patient safety through effective electrical insulation.

In the realm of power electronics, the minimal line width/spacing of 0.1mm on these PCBs allows for high-density designs, which is essential for compact power converters, inverters, and other power control modules. The robust nature of the ceramic substrate PCB also makes it suitable for industrial applications that require a high degree of precision and durability, such as in robotics, automation systems, and harsh environmental conditions.

In conclusion, Ceramic PCB Boards, particularly those with high thermal conductivity, are versatile components that find their use in a wide array of products and scenarios. With the provision of one-stop OEM and DFM services, they offer manufacturers the flexibility to design and produce high-quality electronic devices that meet stringent requirements and operate reliably under a variety of conditions.

Customization:

Our Immersion Gold Ceramic PCB Board offers premium product customization services to meet your specific requirements. With advanced capabilities, we can achieve a Min Line Width/Spacing as fine as 0.1mm , ensuring precision and high-quality circuit delineation.

Our boards come in a variety of sizes, ranging from 2mm to 200mm , to accommodate various applications. The particular Pcb Size for this model is 22mm*19mm , perfectly suited for compact designs that demand high-performance materials.

We specialize in Ceramic Insulated Metal Substrate technology, providing boards with exceptional thermal conductivity. Our 170W/m·K ALN Ceramic PCBs are ideal for high-power circuits, ensuring efficient heat dissipation.

Our ceramic PCBs are available in different technology types, including DBC (Direct Bond Copper) , DPC (Direct Plated Copper) , LTCC (Low-Temperature Co-fired Ceramic) , and HTCC (High-Temperature Co-fired Ceramic) , to match your thermal and electrical performance needs.

The Dielectric Constant of our ceramic PCBs ranges from 6.0-10.0 , accommodating a variety of applications from high-frequency to high-power electronics.

Support and Services:

Our Product Technical Support and Services for the Ceramic PCB Board are dedicated to providing our customers with comprehensive assistance to ensure optimal performance and longevity of their product. Our services include:

Technical Consultation: Our team of experts is available to provide guidance on design considerations, material selection, and layout optimization for your Ceramic PCB Board applications.

Troubleshooting Support: If you encounter any issues with your Ceramic PCB Board, our technical support team is here to help diagnose and resolve problems quickly and efficiently.

Product Documentation: We provide detailed documentation, including specifications, installation guides, and maintenance instructions to facilitate a smooth experience with your Ceramic PCB Board.

Firmware and Software Updates: To ensure your Ceramic PCB Board remains up-to-date and performs at its best, we offer regular firmware and software updates.

Quality Assurance: Our Ceramic PCB Boards undergo rigorous testing to meet high-quality standards. In the unlikely event of a defect, we will provide the necessary support to rectify the issue promptly.

Repair Services: Should your Ceramic PCB Board require repairs, we offer professional repair services to restore your product to its optimal working condition.

We are committed to delivering exceptional support and services to enhance your experience with our Ceramic PCB Board. For any technical inquiries or support needs, please reach out to our customer service team (contact information excluded).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!