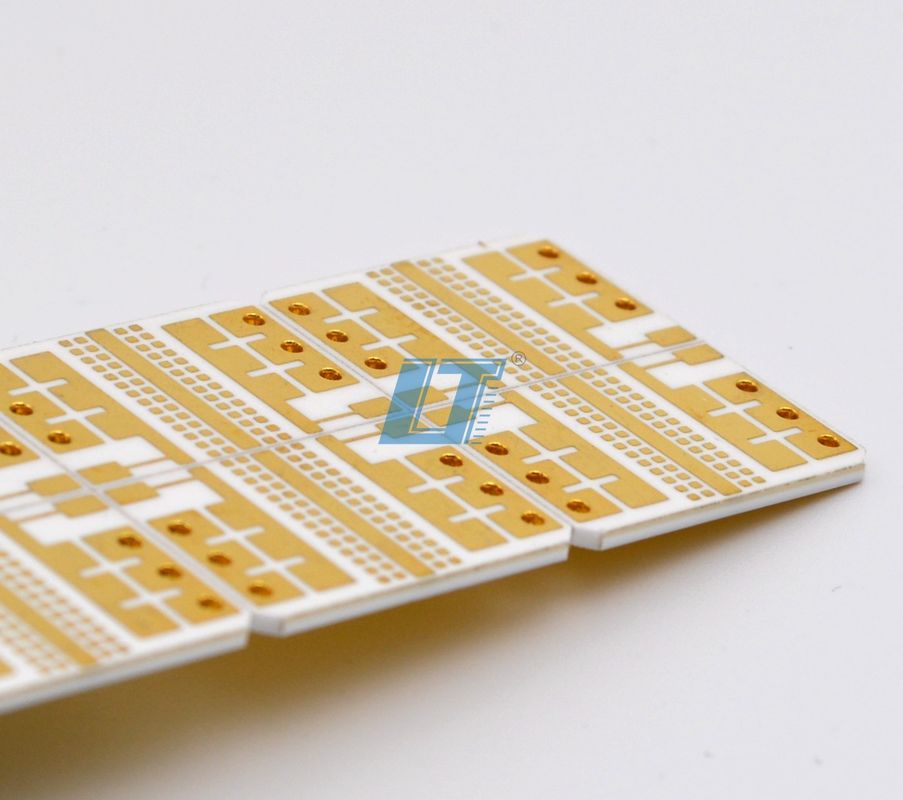

Al2O3/ALN Ceramic PCB Board 0.1mm Min Line Black Solder Mask 170 W/mK Thermal Conductivity

Product Description:

The Immersion Gold Ceramic PCB Board is a state-of-the-art solution for high-end electronics that demand exceptional thermal conductivity and electrical insulation. This product is meticulously designed to cater to sophisticated electronic applications where stability and reliability are paramount. The Ceramic PCB Board combines the durability of ceramics with the efficient conductivity of copper, resulting in a product that significantly outperforms traditional FR4 PCBs in high-temperature environments.

The use of Al2O3 and ALN materials in the fabrication of the Ceramic PCB Board ensures superior heat dissipation and thermal management. Al2O3, or Aluminum Oxide, is known for its excellent electrical insulation properties, high thermal conductivity, and chemical stability. ALN, or Aluminum Nitride, further enhances the board's performance with its exceptional ability to transfer heat, making it an ideal choice for applications requiring rapid heat dissipation. Together, these materials make the Ceramic Copper Clad PCB not just durable but also highly efficient in thermal management.

With a solder mask color of black, the Ceramic PCB Board offers a sleek and professional appearance, which is coupled with improved heat absorption. The black solder mask also provides excellent contrast for silkscreened labels and markings, facilitating easier component identification and board inspection. This aesthetic choice does not compromise the board's functionality but rather complements its high-quality performance.

The Ceramic Copper Clad PCB features an advanced Immersion Gold finish, providing a flat surface that is ideal for fine-pitch components. Immersion Gold, a method of depositing a thin layer of gold over the copper surface, offers exceptional oxidation resistance and provides a robust surface for soldering. This finishing technique ensures a high level of solderability, longevity, and electrical conductivity, making it a preferred choice for high-reliability applications.

Our company takes pride in offering a One-stop Service / OEM, DFM (Design for Manufacturing) service that caters to the entire lifecycle of the Ceramic PCB Board, from design to production. This comprehensive service ensures that our clients receive custom-tailored solutions that meet their specific needs while adhering to the highest standards of quality and performance.

The Immersion Gold Ceramic PCB Board boasts a minimum line width and spacing of 0.1mm, which allows for high-density component placement and ensures signal integrity. This precision in design is critical for modern electronics where space is at a premium, and every millimeter counts. The fine line and spacing capabilities are indicative of the board's suitability for advanced technologies, including those in the medical, aerospace, and telecommunications sectors.

Focusing on the growing demand for high-performance PCBs, the ALN Ceramic PCBs segment is rapidly expanding, owing to their superior thermal properties and electrical performance. The Immersion Gold Ceramic PCB Board is a prime example of this technological advancement, catering to applications that operate under extreme conditions or require high power densities.

In conclusion, the Immersion Gold Ceramic PCB Board represents the pinnacle of PCB technology, blending the thermal and electrical benefits of ceramic substrates with the reliability of copper conductive layers. This product is engineered with precision and manufactured to exceed the expectations of the most demanding electronic applications. With its elegant black solder mask, robust immersion gold surface finish, and precise minimum line width/spacing, this Ceramic PCB Board is the ultimate choice for professionals seeking unparalleled performance in their electronic devices.

Features:

- Product Name: Ceramic PCB Board

- Operating Temperature: -50°C To 150°C

- Material: Al2O3, ALN

- Pcb Name: Immersion Gold Ceramic PCB Board

- Layers: 1-8 Layers

- Surface Technics: ENIG, nickel-palladium GLOD

- Ceramic Substrate PCB

- High thermal conductivity Ceramic PCBs

- 170W/m·K ALN Ceramic PCBs

Technical Parameters:

| Attribute |

Specification |

| Pcb Size |

22mm*19mm |

| Min Line Width/Spacing |

0.1mm |

| Thermal Conductivity |

170 W/mK |

| Dielectric Constant |

6.0-10.0 |

| Surface Finished |

Immersion Gold, nickel-palladium GLOD |

| Size |

2mm~200mm |

| Layers |

1-8 Layers |

| Pcb Name |

Immersion Gold Ceramic PCB Board |

| Product Type |

PCB&PCBAOEM, DFM |

| Operating Temperature |

-50°C To 150°C |

Applications:

The Ceramic PCB Board, featuring materials such as Al2O3 and ALN, caters to a variety of applications where its unique attributes are essential. With a dielectric constant ranging between 6.0 and 10.0, this type of PCB is ideal for scenarios where electrical insulation and thermal conductivity are crucial. The operating temperature range of -50°C to 150°C enables the Ceramic PCB Board to perform reliably in extreme conditions, making it a suitable choice for Ceramic High Temperature PCB applications.

One of the primary applications for Ceramic PCB Boards is in the realm of Direct Bond Copper (DBC) and Direct Plated Copper (DPC) technologies. These techniques are invaluable for high power circuits where efficient heat dissipation is a must. In DBC and DPC, the ceramic substrate acts as an excellent foundation due to its thermal properties and electrical insulation capabilities. This makes the Ceramic PCB Board a top contender for power electronics, automotive industries, and high-performance circuits.

In the field of electronics where miniaturization and high-density packaging are desired, Low-Temperature Co-fired Ceramic (LTCC) and High-Temperature Co-fired Ceramic (HTCC) technologies are commonplace. These methods benefit from the Ceramic PCB Board's material properties, including its ability to withstand high temperatures and maintain structural integrity. The minimal line width and spacing of 0.1mm further allow for complex circuit designs on a compact board, making it the PCB of choice for advanced microelectronics.

Another significant area of application is within the Ceramic Glass Composite PCB sector, where the blend of ceramic and glass materials results in PCBs that are robust and have excellent dielectric properties. Industries that require high-frequency performance often turn to these composite PCBs to take advantage of the low loss tangent and stable dielectric constant provided by the ceramic component.

The versatility of the Ceramic PCB Board is enhanced by the one-stop service/OEM, DFM (Design for Manufacturability) support offered by manufacturers. This customer-oriented service streamlines the process from design to production, ensuring that each Ceramic PCB Board meets the specific requirements of the application. Whether for aerospace, medical devices, or high-speed telecommunications, the Ceramic PCB Board stands as a reliable and efficient solution.

Customization:

Our Immersion Gold Ceramic PCB Board is designed with precision to cater to your specific needs in electronic applications. With a PCB size of 22mm*19mm, this board is compact yet powerful. It is perfect for those who require a high-quality Ceramic Hybrid PCB with a dielectric constant ranging from 6.0-10.0, ensuring superior electrical performance and stability.

This Al2O3 Ceramic PCBs product boasts a robust and reliable surface finish of Immersion Gold with an additional layer of nickel-palladium GLOD, providing excellent conductivity and corrosion resistance. As a leading provider of PCB&PCBAOEM,DFM services, we understand the importance of customization and are committed to delivering a Ceramic Dielectric PCB that meets your exact specifications.

Whether you are in need of a single prototype or mass production, our product customization services are here to offer you the best in class Immersion Gold Ceramic PCB Board designed for high-performance and durability. Contact us to learn how we can assist you in achieving optimal results with our tailored solutions.

Support and Services:

Our Ceramic PCB Board product comes with comprehensive technical support and services designed to ensure your satisfaction and success with our product. We offer a range of services to help you with any technical challenges you may face, including but not limited to:

Technical Consultation: Our team of experts is available to provide you with guidance on design considerations, material selection, and best practices for integrating our Ceramic PCB Board into your project.

Product Documentation: We supply thorough documentation covering specifications, handling instructions, and safety guidelines to help you understand and utilize the product effectively.

Troubleshooting Assistance: If you encounter any issues while using our Ceramic PCB Board, our technical support team is on hand to help diagnose and solve your problems, ensuring minimal downtime and continued productivity.

Quality Assurance: Our Ceramic PCB Boards undergo rigorous quality control procedures to guarantee high performance and reliability. If you have any concerns about the quality or performance of your product, we are prepared to address them promptly.

Updates and Upgrades: We keep our customers informed about any updates or upgrades available for their Ceramic PCB Boards, ensuring that your product remains at the cutting edge of technology.

Custom Support Solutions: Should you require specialized support, we are ready to work with you to develop custom solutions tailored to meet the unique needs of your application.

Our commitment to providing exceptional technical support and services is unwavering. We strive to ensure that your experience with our Ceramic PCB Board is as smooth and beneficial as possible. Please refer to your product documentation for specific details on how to access these support services.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!