Product Description:

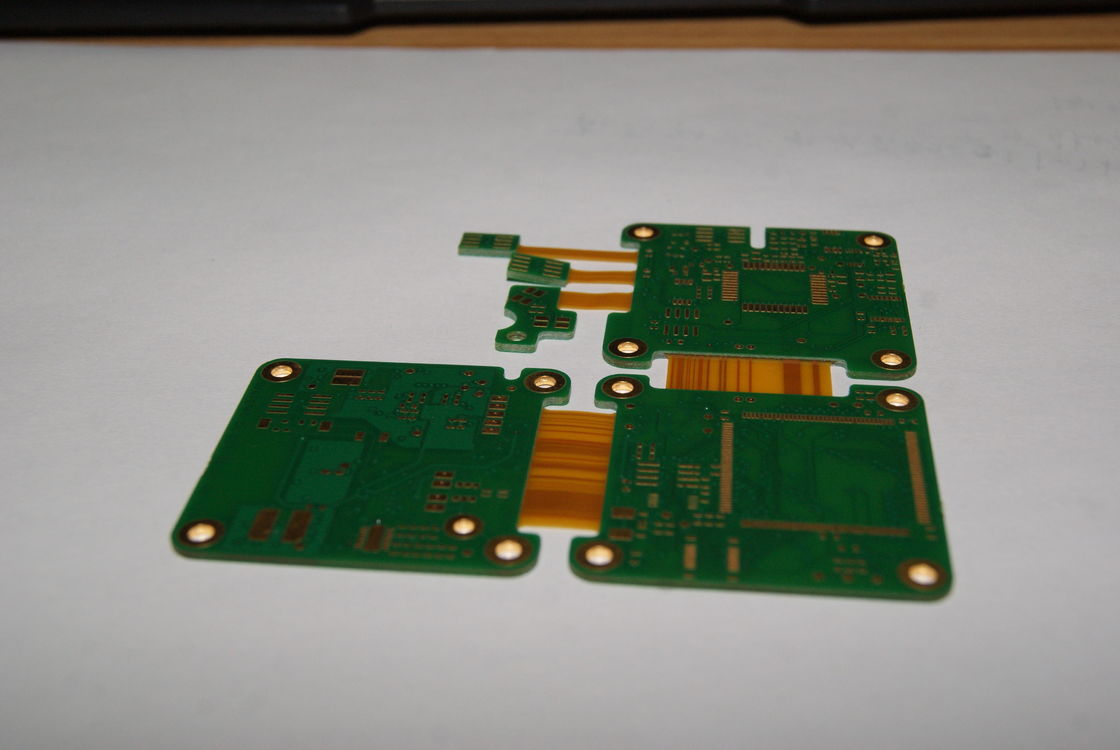

Welcome to our product summary for the Rigid Flex PCB, a cutting-edge solution that combines the best of both rigid and flexible circuit boards. This innovative product offers unparalleled versatility and reliability, making it ideal for a wide range of applications.

With a layer count of 16 layers, our Rigid Flex PCB provides ample space for complex designs and intricate circuitry. Whether you are working on a high-density electronic device or a sophisticated control system, this product can meet your requirements with ease.

One of the standout features of our Rigid Flex PCB is its flexible-bendable design, which allows it to be folded and shaped to fit into tight spaces or unconventional configurations. This flexibility opens up a world of possibilities for designers and engineers, enabling them to create compact and efficient electronic systems.

When it comes to stiffener options, our Rigid Flex PCB offers a choice of Polyimide, FR4, and Stainless Steel. These stiffener materials provide structural support and rigidity to the board, ensuring that it maintains its shape and integrity even under challenging conditions.

The surface finishing of our Rigid Flex PCB is Lead Free HASL, which offers excellent solderability and corrosion resistance. This high-quality finish ensures reliable performance and longevity, making our product suitable for demanding applications where durability is essential.

With a maximum layer count of 52L, our Rigid Flex PCB pushes the boundaries of what is possible in terms of complexity and functionality. Whether you need a simple single-layer design or a multi-layered circuit board with intricate routing, this product can accommodate your needs with precision and reliability.

Our Rigid Flex PCB supports a wide range of components, including SMD (Surface Mount Devices), BGA (Ball Grid Array), DIP (Dual In-line Package), and many more. This versatility makes it a versatile solution for diverse electronic applications, from consumer electronics to industrial control systems.

In conclusion, our Rigid Flex PCB is a state-of-the-art solution that combines the flexibility of a flexible circuit board with the rigidity of a traditional printed wiring board. With its foldable design, multiple layer options, and wide component compatibility, this product is the perfect choice for projects that require a high degree of customization and performance.

Features:

-

Product Name: Rigid Flex PCB

-

Max Layer: 52L

-

Outer: Carton Box

-

Min Line Space: 8mil

-

Thickness: 0.6mm

-

Features: Gerber/PCB File Needed

-

Key Attributes: Flexible-Bendable PCB, Flexible Rigid Circuit Board, Bendable Printed Circuit Board

Technical Parameters:

|

Features

|

Gerber/PCB File Needed

|

|

Size

|

9*9cm

|

|

Max Layer

|

52L

|

|

Surface Treatment

|

HASL Lead Free, Immersion Gold

|

|

Finished Copper

|

1OZ

|

|

Surface Finishing

|

Lead Free HASL

|

|

Stiffener Options

|

Polyimide, FR4, Stainless Steel

|

|

Components

|

SMD, BGA, DIP, Etc.

|

|

Processing

|

Assembly

|

|

Min Line Space

|

8mil

|

Applications:

The Min. Line Width/Spacing of 0.075mm/0.075mm ensures high precision and accuracy in electrical connections, making Rigid Flex PCBs ideal for intricate electronic devices. Whether it's a Flex Rigid PCB or a Flexible Stiff Circuit Board, these products can be customized to meet specific design requirements.

The Rigid Flex PCBs come packaged in durable Carton Boxes, providing protection during transportation and storage. The boards require Gerber/PCB files for manufacturing, ensuring seamless production processes and precise replication of designs.

These boards are suitable for a wide range of Product Application Occasions and Scenarios. They are commonly used in industries such as aerospace, medical devices, automotive, and consumer electronics. In aerospace applications, Rigid Flex PCBs are used in avionics systems, where reliability and performance are critical. In the medical field, these boards are utilized in medical imaging equipment and implantable devices.

In the automotive industry, Rigid Flex Printed Wiring Boards are integrated into advanced driver assistance systems and engine control units. For consumer electronics, these boards are found in smartphones, tablets, and wearables, where space optimization and reliability are essential.

Overall, Rigid Flex PCBs offer a reliable and efficient solution for complex electronic systems across various industries, making them a preferred choice for designers and engineers looking for high-performance circuit boards.

Customization:

Product Customization Services for Flex-Rigid Printed Circuit Board:

Outer: Carton Box

Components: SMD, BGA, DIP, Etc.

Stiffener Options: Polyimide, FR4, Stainless Steel

Solder Mask Colour: Green

Size: 9*9cm

Support and Services:

Our Product Technical Support and Services for the Rigid Flex PCB include:

- Expert assistance with design considerations and material selection

- Guidance on manufacturing processes and best practices

- Troubleshooting support for any issues encountered during production

- Customized solutions to meet specific project requirements

- Training and resources to help customers maximize the performance of Rigid Flex PCBs

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!