Product Description:

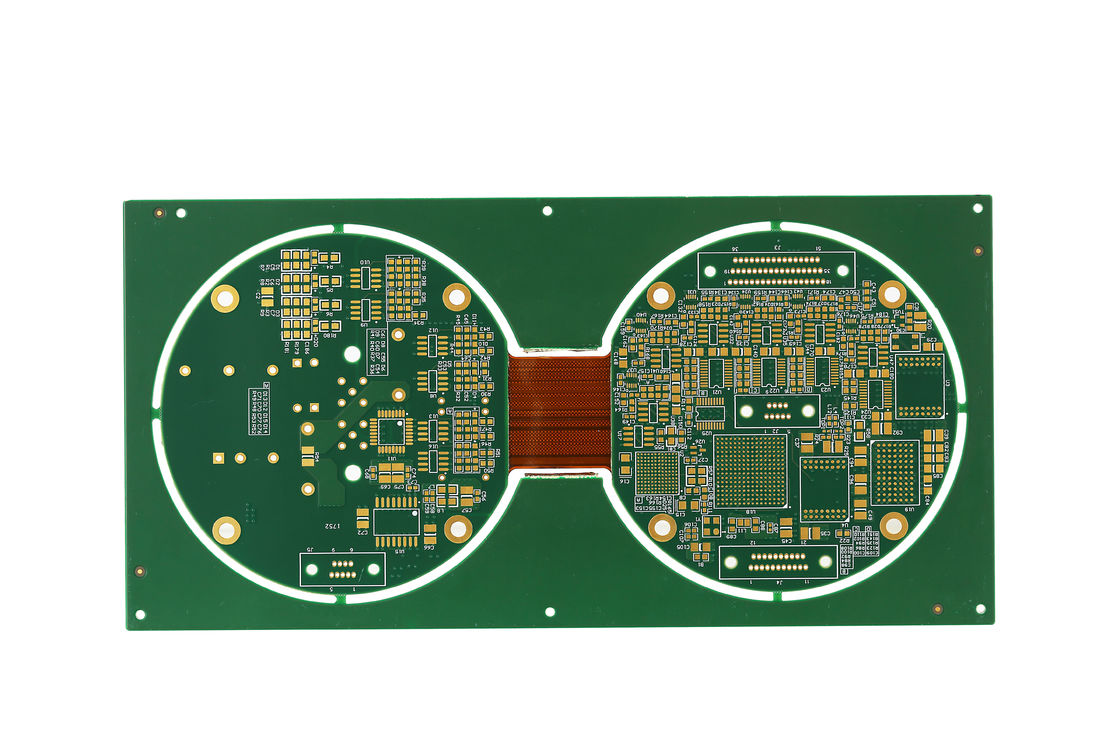

The Rigid Flex PCB is an innovative solution that encapsulates the benefits of both rigid and flexible circuit technologies into a single board. This hybrid technology is designed to meet the rigorous demands of modern electronic devices that require a flexible stiff circuit board capable of accommodating complex designs and ensuring high reliability. The Rigid Flex PCB is characterized by its unique ability to bend, fold, and flex, which is essential in applications where space is at a premium and the movement of the components is necessary.

One of the key attributes of this product is its bend radius, which ranges from a very tight 0.5mm up to a more generous 10mm. This allows for a significant degree of flexibility when designing the layout of electronic components, ensuring that the board can be folded or bent to fit into the desired configuration without compromising the integrity of the circuits. The flexibility of the board is rated from 1 to 8 times, which denotes the number of times the board can be flexed without failure. This range ensures that the Rigid Flex PCB can accommodate a variety of applications, from those requiring a single, gentle bend to those that need to withstand multiple flexing cycles.

As a product type, the Rigid Flex PCB falls under the PCB Assembly category, which signifies that it is not just a bare circuit board but a comprehensive assembly ready for the integration of electronic components. The board is engineered to seamlessly combine the mechanical stability of a rigid PCB with the adaptability of a flexible circuit, resulting in a foldable rigid circuit board that provides superior performance and durability.

The Rigid Flex PCB is proficiently crafted with a 4 layer design, which allows for a complex and multi-functional circuitry within a compact footprint. This multilayer construction is beneficial for high-density applications where space-saving is crucial. The layers are strategically designed to provide the necessary electrical performance while maintaining the board's flexibility.

Profiling punching is a vital process in the manufacturing of PCBs, and our Rigid Flex PCB employs several profiling techniques including routing, V-CUT, and beveling. Routing is used to create intricate shapes and designs, providing the flexibility to customize the board to fit specific requirements. V-CUT is utilized to score the board, facilitating easier breaking or bending at designated lines. Beveling, on the other hand, is used to create angled edges on the connectors to ensure a smooth insertion into the mating component. These profiling processes are meticulously executed to ensure that the Rigid Flex PCB meets the highest standards of precision and quality.

The Rigid Flex PCB is not only versatile in its application but is also recognized for its reliability and robustness. The combination of rigid and flexible layers results in a flexible rigid circuit board that can withstand the thermal and mechanical stresses encountered during the operation of electronic devices. It also provides improved signal integrity and reduces the need for multiple connectors, leading to a reduction in potential failure points within the system.

In summary, the Rigid Flex PCB is a remarkable product that offers the best of both worlds in circuit board technology. With its variable bend radius, multiple profiling punching options, 4 layer design, and rated flexibility, this PCB assembly stands out as an ideal solution for advanced electronic applications. Its ability to serve as a flexible stiff circuit board, a foldable rigid circuit board, and a flexible rigid circuit board makes it an indispensable component in the realm of electronics manufacturing.

Features:

- Product Name: Rigid Flex PCB

- Flexibility: 1-8 Times

- Product Type: PCB Assembly

- Sanforized: Local High Density, Back Drill

- Profiling Punching: Routing, V-CUT, Beveling

- Components: SMD, BGA, DIP, Etc.

- Keywords:

- Foldable Rigid Circuit Board

- Flexible-Bendable PCB

- Foldable Rigid Circuit Board

Technical Parameters:

| Technical Parameter |

Specification |

| Surface Finishing |

HASL LF |

| Flexibility |

1-8 Times |

| Profiling Punching |

Routing, V-CUT, Beveling |

| Hole Position Deviation |

±0.05mm |

| No Of Layers |

4 Layer |

| Treatment |

ENIG/OSP/Immersion Gold/Tin/Silver |

| Pcb Layer |

1-28layers |

| Sanforized |

Local High Density, Back Drill |

| Dimension |

41.55*131mm |

| Product Type |

PCB Assembly |

Applications:

The Rigid Flex PCB, with its advanced Surface Finishing of HASL LF (Hot Air Solder Leveling Lead-Free), represents a remarkable fusion of rigid and flexible circuit technologies. A Rigid Flexible Printed Circuit Board (RFPCB) combines the durability of rigid PCBs with the adaptability of flexible circuits, allowing for a dynamic range of applications across various industries. With a maximum layer count of 52L (52 layers), this product is at the forefront of multi-layered PCB capabilities, providing exceptional electrical performance and high-density interconnection for complex designs.

Given its impressive dimensions of 41.55*131mm, the Rigid Flex PCB is designed to fit into compact spaces without sacrificing functionality. It accommodates a vast array of components including SMD (Surface Mount Devices), BGA (Ball Grid Array), DIP (Dual In-line Package), etc., making it suitable for intricate electronic assemblies where space and reliability are at a premium. The Rigid Flexible Printed Circuit Board can be found in high-end applications such as aerospace, military, and medical devices, where the combination of flexibility and robustness is crucial.

One of the key attributes of this product is its Flexible-Bendable PCB feature, which allows it to be bent or folded to conform to small or irregularly shaped spaces without damaging the circuitry. This makes it ideal for wearable technology, foldable screens, and devices where the PCB must navigate around mechanical parts or fit within curved surfaces. The RFPCB's profiling punching capabilities, including Routing, V-CUT, and Beveling, enable precise board outlines and easy assembly of the boards into housings or fixtures, further enhancing its versatility.

Applications for the Rigid Flex PCB are vast, ranging from consumer electronics where the Flexible-Bendable PCB trait is leveraged for devices like smartphones and cameras, to automotive industry applications where the ability to withstand harsh environments and vibrations is paramount. In the field of telecommunications, these boards are essential for ensuring high-speed signal transmission and mechanical stability within the compact frameworks of communication devices. Additionally, industrial equipment that requires reliable and durable circuitry under strenuous conditions can greatly benefit from the robust nature of the Rigid Flexible Printed Circuit Board.

In summary, the Rigid Flex PCB product is a state-of-the-art solution designed to meet the ever-increasing demands for electronic devices that require a combination of flexibility, space efficiency, and durability. Its comprehensive features, including HASL LF finishing, up to 52L of layering, and sophisticated profiling punching techniques, render it an invaluable component for a multitude of cutting-edge applications.

Customization:

Our Rigid Flex PCB product offers a range of customization services to meet your exact requirements. With a 4 Layer configuration, our Rigid Flex Printed Wiring Board provides a robust structure for your applications. We ensure precise Hole Position Deviation of ±0.05mm, allowing for high-precision component placement. The Flex Rigid PCB can accommodate Bend Radius specifications from 0.5-10mm, offering versatility for Foldable Rigid Circuit Board designs. The Surface Finishing is HASL LF, ensuring reliable solderability and protection for your circuits. We utilize top-grade materials such as FR4, Polyimide, and PET to fabricate a PCB that meets your specific needs.

Support and Services:

The Rigid Flex PCB combines the best of both rigid boards and flexible circuits integrated into one unit, allowing for a more versatile range of applications. Our technical support and services ensure that all our clients receive comprehensive assistance throughout the lifecycle of their product. Our support includes design guidance, material selection advice, and troubleshooting assistance to ensure that your Rigid Flex PCB performs to its full potential. We also provide detailed documentation and resources to help you understand the best practices for handling and integration of our PCBs into your projects. Additionally, our service team is dedicated to providing timely and effective solutions to any technical challenges that may arise, ensuring your operations run smoothly and efficiently.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!