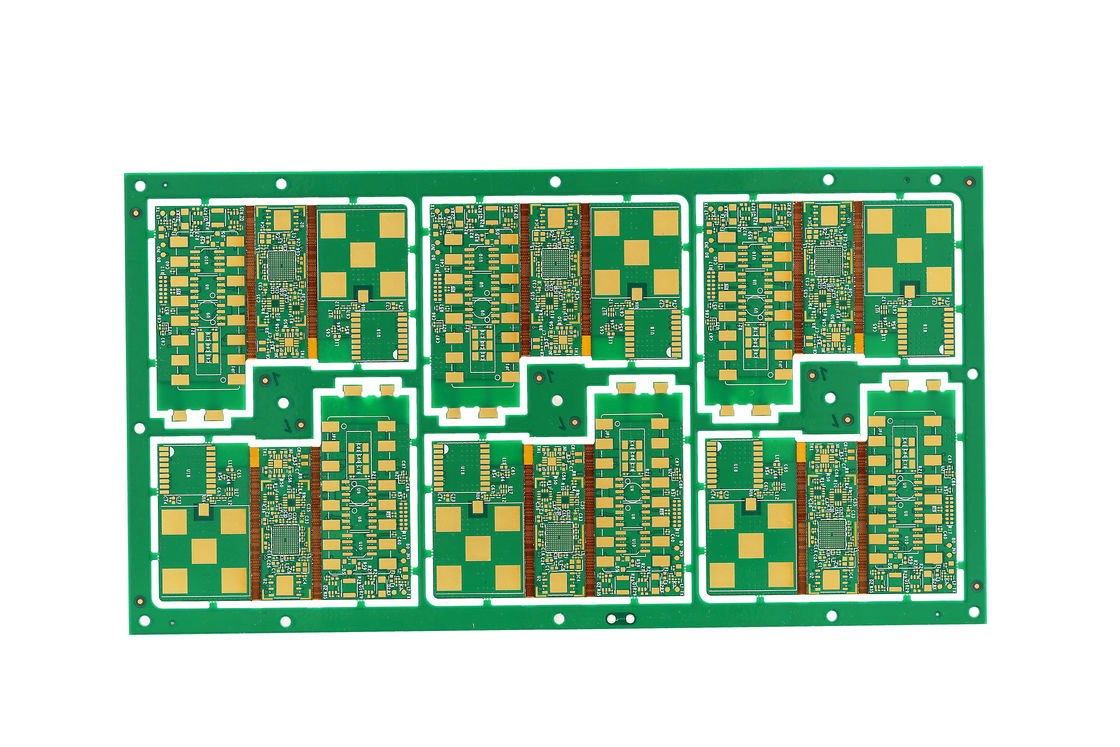

4 Layer Rigid Flex Pcb Assembly Enig Treatment 1-28Layers Profiling Punching 0.5-10Mm Bend Radius

Product Description:

The Rigid Flex PCB, also known as the Flex-Rigid Printed Circuit Board, represents a remarkable fusion of robustness and flexibility, designed to meet the stringent demands of modern electronics. This hybrid circuit board combines the best attributes of rigid printed circuit boards and flexible circuits to offer an unparalleled level of versatility and reliability. With the capability to bend and twist without compromising the integrity of the electrical connections, this Bendable Printed Circuit Board is an ideal solution for dynamic applications where space is at a premium and complex three-dimensional configurations are necessary.

One of the most critical specifications of any PCB is the precision of hole locations, and our Rigid Flex PCB boasts an impressive hole position deviation of ±0.05mm. This level of accuracy ensures that components fit perfectly, and the board operates as intended, even in the most complex assemblies. The precision in manufacturing extends to the overall dimensions of the board, which measures 41.55*131mm, making it suitable for a wide range of applications from medical devices to aerospace instrumentation.

The materials used in the construction of the Rigid Flex PCB are carefully selected to provide the best performance and durability. FR4 is a widely respected composite material known for its excellent flame resistance, electrical insulation properties, and mechanical strength. Polyimide is used for the flexible layers of the board due to its outstanding thermal stability, chemical resistance, and flexibility. Additionally, PET, known for its good balance of mechanical and electrical properties, is also utilized to enhance the board's performance. Together, these materials create a Flex-Rigid Printed Circuit Board that is not only bendable but also durable and capable of operating in challenging environments.

In terms of layering, the Rigid Flex PCB is truly remarkable, supporting configurations of up to 52L (Max Layer). This extraordinary layer count enables the integration of multiple circuits into a single, compact package, which is essential for high-density electronic applications. Whether it's for advanced communication equipment, sophisticated control systems, or cutting-edge medical technology, the ability to accommodate such a high number of layers makes this PCB a go-to choice for designers and engineers.

Surface treatment is another aspect where our Flex-Rigid Printed Circuit Board stands out. Customers can choose from a variety of finishes, including ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservatives), Immersion Gold, Immersion Tin, and Immersion Silver. Each of these treatments is applied to ensure the best possible surface for soldering, longevity, and protection against oxidation. ENIG offers excellent surface planarity and a long shelf life, making it ideal for fine-pitch components. OSP is a cost-effective and environmentally friendly choice that provides a flat surface and is suitable for lead-free soldering. Immersion Gold, Tin, and Silver all offer their unique benefits, from excellent conductivity to superior solderability.

In conclusion, the Rigid Flex PCB is a sophisticated, high-performance solution that bridges the gap between traditional rigid PCBs and flexible circuits. Its precision, material quality, high layer count, and versatile surface treatments make it a powerful choice for a multitude of applications. Whether you are looking to push the boundaries of electronic design or seeking a reliable and space-efficient circuit board, this Bendable Printed Circuit Board is engineered to go beyond the expectations of the most demanding projects.

Features:

- Product Name: Rigid Flex PCB

- Bend Radius: 0.5-10mm

- Hole Position Deviation: ±0.05mm

- Flexibility: 1-8 Times

- Pcb Layer: 1-28 layers

- Max Layer: 52L

- Type: Rigid Flexible Printed Circuit Board

- Design: Flex-Rigid Printed Circuit Board

- Structure: Rigid Flex Printed Wiring Board

Technical Parameters:

| Technical Parameter |

Description |

| No Of Layers |

4 Layer |

| Dimension |

41.55*131mm |

| Max Layer |

52L |

| Sanforized |

Local High Density, Back Drill |

| Hole Position Deviation |

±0.05mm |

| Profiling Punching |

Routing, V-CUT, Beveling |

| Components |

SMD, BGA, DIP, Etc. |

| Material |

FR4, Polyimide, PET |

| Treatment |

ENIG/OSP/Immersion Gold/Tin/Silver |

| Bend Radius |

0.5-10mm |

Applications:

The Rigid Flex PCB, a hybrid construction of Rigid Flexible Printed Circuit Boards, offers a unique solution to complex electronic challenges. With a dimension of 41.55*131mm, this product is specifically designed to cater to applications that require the perfect blend of flexibility and rigidity. The utilization of high-quality materials such as FR4, Polyimide, and PET ensures durability and long-term reliability, while the Surface Finishing with HASL LF provides excellent solderability and environmental protection.

One of the primary applications for this Rigid Flexible Printed Circuit Board is in wearable technology. The flexibility allows for ergonomic designs that can conform to various shapes and contours of wearable devices. Moreover, the slim profile and lightweight nature of the board make it an ideal choice for compact spaces and devices that require a minimalistic design approach without compromising on functionality.

Medical devices also benefit greatly from the use of Rigid Flexible Printed Circuit Boards. The ability to create complex three-dimensional structures makes it suitable for intricate medical instruments where reliability and precision are paramount. The board's treatment options, including ENIG, OSP, Immersion Gold/Tin/Silver, ensure excellent conductivity and resistance to oxidation, which are essential attributes in medical environments.

In the aerospace industry, the Flexible Stiff Circuit Board finds its purpose in the production of sophisticated electronics that need to withstand extreme conditions while maintaining a high level of precision. The board's profiling punching options, such as Routing, V-CUT, and Beveling, allow for a seamless integration into various aerospace components, offering enhanced performance and reducing the risk of mechanical stress.

Furthermore, the defense sector utilizes the robustness of the Rigid Flexible Printed Circuit Board for communication devices and advanced control systems. The combination of flexible and rigid areas within a single circuit board provides the necessary resilience and adaptability needed in the field, where equipment is expected to endure rugged conditions without failure.

Consumer electronics manufacturers also incorporate these boards into devices like smartphones, cameras, and other handheld gadgets. The compact and versatile nature of the Rigid Flex PCB allows for innovative design possibilities, enabling slimmer profiles and more complex functionalities packed into smaller form factors.

In summary, the Rigid Flex PCB product with its substantial attributes is a quintessential component for applications demanding high reliability, precision, and design flexibility, making it a valuable asset in a multitude of high-tech industries.

Customization:

Our Rigid Flex PCB product offers comprehensive Product Customization Services to meet your specific needs. With a maximum layer count of up to 52L, our PCB Assembly services provide versatility for even the most complex designs. Whether you need a 4 Layer board or more, we can accommodate your requirements.

Our Bendable Printed Circuit Board technology ensures that you can have the flexibility where you need it, while maintaining the stability of a Rigid Printed Wiring Board. With a minimum trace and space of 0.1mm, we ensure high-density interconnectivity for your device’s functionality.

The standard dimension of our Flex Rigid PCB is 41.55*131mm, which provides ample space for a variety of components and complex circuit designs while still being able to fit into your compact device. Custom sizes are also available upon request to meet your specific design constraints.

Choose our Rigid Flex PCB services for a Bendable Rigid Printed Wiring Board solution that combines reliability with the dynamic capabilities of a flex circuit. Contact us today to get started on your custom PCB project.

Support and Services:

Rigid Flex PCBs are advanced circuit boards that combine the best of both rigid boards and flexible circuits. Our product technical support and services for Rigid Flex PCBs provide comprehensive assistance to ensure the highest quality and performance of your circuitry needs. We offer design guideline consultations to help you optimize your layout for manufacturing efficiency and reliability. Our engineering team is available to support you with any questions related to material selection, stack-up options, and electrical performance requirements.

We also provide detailed documentation for assembly and handling instructions, ensuring that your team can appropriately manage and assemble the Rigid Flex PCBs without compromising their integrity. Our testing services include electrical testing to guarantee that each PCB meets the stringent quality standards before being shipped. We utilize advanced inspection techniques, including Automated Optical Inspection (AOI), X-ray inspection, and flying probe tests, to detect any potential issues early in the production process.

For any troubleshooting or technical issues that may arise, our dedicated support team is prepared to provide prompt solutions. We offer guidance through potential challenges such as flex cracking, delamination, or conductor integrity problems. Our goal is to help you mitigate these issues and extend the lifespan of your Rigid Flex PCBs.

In the event of product updates or revisions, we ensure seamless transition support, helping you adapt to new versions with minimal disruption. Our commitment to customer satisfaction means that we are constantly striving to provide you with the resources and expertise you need to succeed with Rigid Flex PCB technology.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!