Product Description:

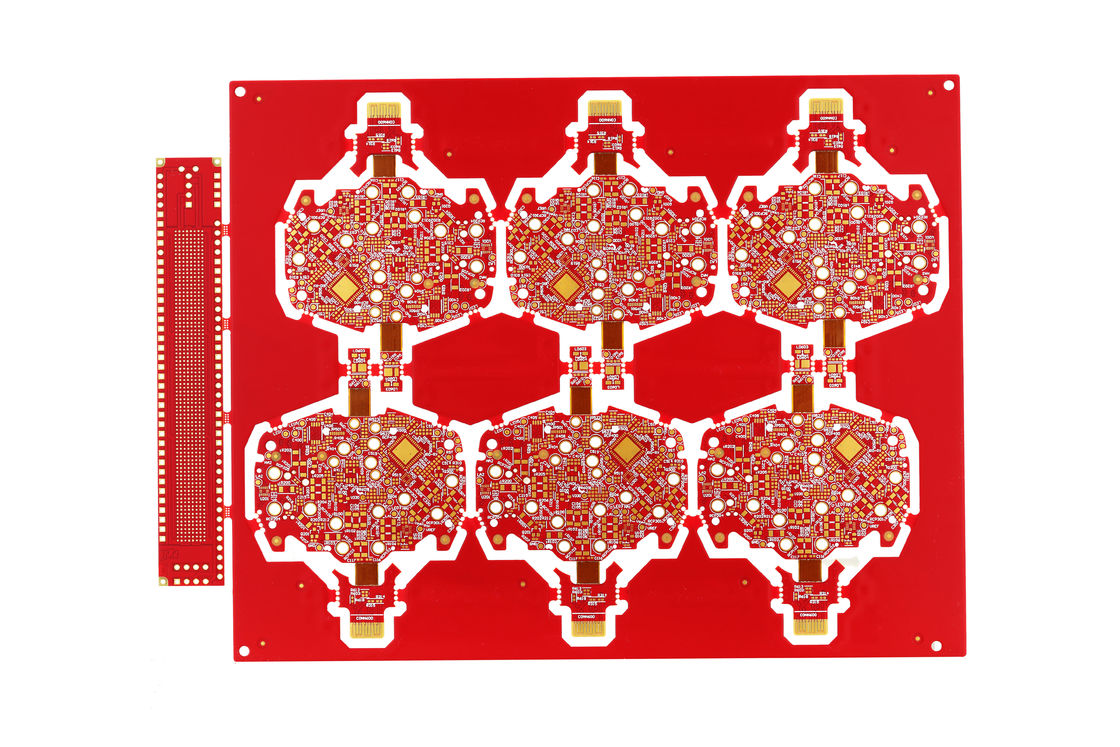

The Rigid Flex PCB product represents a remarkable fusion of the robustness offered by traditional rigid printed circuit boards (PCBs) and the versatile adaptability of flexible circuits. This hybrid technology incorporates elements from both rigid and flexible circuitry, creating a board that is both sturdy and bendable. It opens up new dimensions for electronic designers, offering the resilience needed for stable components alongside the malleability required for intricate electronic assemblies.

The Rigid Flex Printed Wiring Board is designed with a minimum trace/space specification of 0.1mm, ensuring high-density component placement and a compact, efficient design. With the ability to support a PCB layer count ranging from 1 to 28 layers, it is evident that these boards are crafted to accommodate a variety of complexities and functionalities, suitable for numerous applications across diverse industries.

As a product type classified under PCB Assembly, this Rigid Flex PCB is more than a bare board; it is a comprehensive solution that includes the integration of various components. The assembly process takes advantage of cutting-edge technology to place surface-mounted devices (SMDs), ball grid arrays (BGAs), dual in-line packages (DIPs), and other electronic components with precision and reliability. The inclusion of these components makes the product a ready-to-use electronic foundation for a myriad of applications that require both the stability of rigid areas and the flexibility of bendable segments.

The Flexible Stiff Circuit Board is fabricated with meticulous attention to detail, employing various profiling punching techniques such as routing, V-CUT, and beveling. These methods ensure that the board is shaped and contoured to exact specifications, facilitating seamless integration into the final product assembly. Routing is utilized for intricate cutouts and shapes, V-CUT for creating easy separation of multiple boards, and beveling for angled edges that enhance the ease of inserting PCBs into connectors.

With its hybrid construction, the Bendable Printed Circuit Board is an ideal solution for applications with spatial constraints or where movement and flexibility are essential. The rigid sections provide a durable base for heavy or heat-generating components, while the flexible tails can be bent or twisted to form the necessary connections without compromising the integrity of the electrical pathways. This dynamic feature of the Rigid Flex PCB enables it to be folded or twisted to fit into tight spaces, eliminating the need for multiple connectors and cables, thus reducing the overall size and weight of the product.

The Rigid Flex PCB's adaptability is not just limited to its physical form. Its electrical performance is equally impressive, with the ability to maintain a high level of signal integrity even in complex, high-speed designs. This makes the product an excellent choice for sophisticated electronic devices where performance and reliability are paramount.

Quality assurance is a central aspect of the manufacturing process for the Rigid Flex PCB. Every board is subjected to rigorous testing and inspection to guarantee that it meets the highest standards of reliability and functionality. This meticulous quality control ensures that each Rigid Flex Printed Wiring Board performs to its full potential, providing a dependable and long-lasting electronic foundation for any application it is designed for.

In summary, the Rigid Flex PCB product is an exceptional choice for designers who require the mechanical precision of a rigid board with the added advantage of flexibility. Its minimum trace/space of 0.1mm, capability to incorporate 1-28 layers, advanced assembly with SMD, BGA, DIP components, and the use of profiling punching techniques come together to create a versatile, high-performance product that stands at the forefront of PCB technology.

Features:

- Product Name: Rigid Flex PCB

- Hole Position Deviation: ±0.05mm

- Bend Radius: 0.5-10mm

- Components: SMD, BGA, DIP, Etc.

- Minimum Trace/Space: 0.1mm

- Flexibility: 1-8 Times

- Bendable Printed Circuit Board

- Bendable Rigid Printed Wiring Board

- Flexible-Bendable PCB

Technical Parameters:

| Technical Parameter |

Specification |

| Sanforized |

Local High Density, Back Drill |

| Max Layer |

32L |

| Bend Radius |

0.5-10mm |

| Surface Finishing |

HASL LF |

| Pcb Layer |

1-28layers |

| Dimension |

41.55*131mm |

| Flexibility |

1-8 Times |

| Components |

SMD, BGA, DIP, Etc. |

| Product Type |

PCB Assembly |

| No Of Layers |

4 Layer |

Applications:

The Rigid Flex PCB, or Bendable Rigid Printed Wiring Board, is a marvel in the electronic components industry, amalgamating the best attributes of rigid and flexible circuit boards. Designed for versatility, this product caters to an extensive array of applications, suitable for various occasions and scenarios where traditional PCBs might not suffice. With a layer count ranging from 1 to 28 layers, it provides ample complexity and connectivity for sophisticated electronic systems.

One of the most prominent features of this Flex-Rigid Printed Circuit Board is its flexibility, which can be utilized from 1 to 8 times. This attribute makes it ideal for applications where the board must conform to a certain shape or fit into irregular spaces. The flexibility also allows for dynamic applications where the board may need to bend during use, accommodating mechanical movements within the device without sacrificing performance or reliability.

Moreover, the bend radius of these boards is quite accommodating, ranging from a tight 0.5mm to a more generous 10mm. This range ensures that whether the application requires sharp bends or gentle curves, the Bendable Printed Circuit Board can handle the stress without compromising its structural integrity or electrical functionality. The dimensions of these boards are precisely 41.55 by 131mm, which speaks to their adaptability in size-restricted environments.

The concept of sanforization also applies to these PCBs, with local high-density areas and back drilling techniques employed to enhance signal integrity and reduce noise. This feature is particularly beneficial in applications where high-speed signals are a norm, and maintaining signal clarity is paramount. These areas of high density allow for more components to be placed in a smaller area while the back drilling helps in reducing the parasitic capacitance and inductance.

Applications for the Rigid Flex PCB are wide-ranging, finding a place in the medical industry for wearable monitors and imaging equipment, in aerospace for cockpit controls and instrumentation, and in the military for rugged, reliable communication devices. Consumer electronics also benefit from this technology, with foldable smartphones, smartwatches, and sophisticated cameras utilizing the tailor-made solutions that these PCBs offer. Additionally, automotive applications, where space is at a premium and reliability under stress is crucial, are perfect scenarios for implementing Rigid Flex PCB technology.

In summary, the Rigid Flex PCB product is an exemplary solution for scenarios demanding high-density packaging, exceptional reliability, and the unique ability to interface between static and dynamic components. Its attributes of multi-layering, flexibility, variable bend radius, and precise dimensioning, combined with sanforization, make it a go-to choice for cutting-edge electronic innovations across a multitude of industries.

Customization:

At our company, we specialize in providing top-tier Product Customization Services for the Rigid Flex PCB product, which ingeniously combines the benefits of both flexibility and rigidity in one solution. Our Flexible Stiff Circuit Board options come with a diverse range of customizable features to meet your specific needs.

We offer a comprehensive range of PCB Layers, from 1-28 layers, ensuring that whether your project is simple or complex, we have the capability to deliver the exact Rigid Flex PCB configuration you require.

Understanding the importance of flexibility in certain applications, our Flexible Rigid Circuit Board can be designed to withstand 1-8 Times of bending without compromising the integrity of the electrical connections. This feature makes our products a perfect fit for dynamic applications where movement is a factor.

When it comes to materials, we provide a selection that includes FR4, Polyimide, and PET, allowing you to choose the ideal substrate based on your product’s thermal, chemical, and mechanical requirements. This material versatility ensures that your Bendable Rigid Printed Wiring Board will be perfectly attuned to your specific operational environment.

Our component placement service is capable of accommodating various types of components such as SMD, BGA, DIP, etc., ensuring that your Rigid Flex PCB is populated with precision and tailored to your circuitry needs.

We are also meticulous about the accuracy of our hole positioning, maintaining a Hole Position Deviation of ±0.05mm, which underscores our commitment to high precision and quality in every Rigid Flex PCB we produce.

Support and Services:

Our Rigid Flex PCB products come with comprehensive technical support and services designed to ensure smooth integration and maintenance throughout their lifecycle. Our support includes detailed product documentation, an extensive knowledge base, and access to a range of technical resources. Customers can benefit from our expert guidance on design considerations, material selection, and layout recommendations to optimize performance and reliability.

We also offer advanced troubleshooting assistance to address any operational issues that may arise. Our support services aim to provide quick and effective solutions to maintain the continuous operation of your Rigid Flex PCB applications. Additionally, we provide updates and upgrades information to keep your product up-to-date with the latest advancements in PCB technology.

Training services are available to help your team get up to speed on the best practices for handling and working with Rigid Flex PCBs. From design engineers to assembly staff, our training modules are tailored to meet the needs of various roles within your organization.

Please note that our product technical support and services are available during standard business hours and we strive to provide prompt responses to all inquiries. We are committed to delivering exceptional service and support to ensure the success of your projects involving Rigid Flex PCBs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!