Product Description:

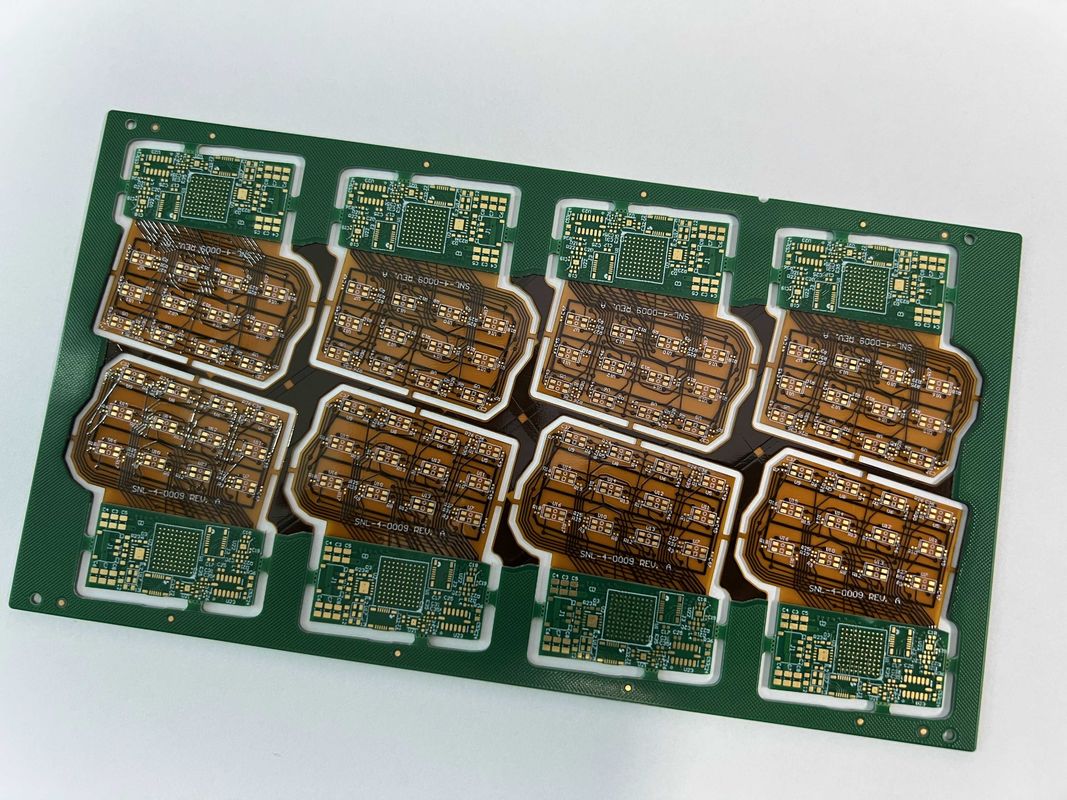

A Flex-Rigid Printed Circuit Board (PCB) is a specialized type of circuit board that combines flexibility and rigidity in one design, offering unique advantages for various applications. Our Rigid Flex PCB product is a high-quality solution that excels in performance and durability, making it ideal for demanding electronic projects.

One of the key features of our Rigid Flex PCB is the surface finishing with Lead Free HASL (Hot Air Solder Leveling). This surface finishing ensures excellent solderability and protection for the PCB, enhancing its overall reliability and longevity.

With a minimum line width and spacing of 0.075mm/0.075mm, our Flexible Rigid Circuit Board provides precise and efficient routing for intricate circuit designs. This fine line capability allows for dense component placement and intricate trace routing, making it suitable for advanced electronic applications that require high precision.

When it comes to processing, our Rigid Flex PCB is designed for assembly, allowing for seamless integration of electronic components onto the board. The assembly process is streamlined and efficient, ensuring that the final product meets the highest quality standards and performance requirements.

Our Rigid Flex PCB features a finished copper weight of 1oz, providing a reliable and stable conductive layer for the circuit traces. The 1oz copper ensures optimal electrical performance and thermal management, making the PCB suitable for a wide range of electronic devices and systems.

For enhanced aesthetics and protection, the solder mask color of our Rigid Flex PCB is green. The green solder mask not only gives the PCB a professional look but also provides insulation and protection for the circuit traces, preventing short circuits and environmental damage.

In conclusion, our Rigid Flex PCB product offers a premium solution for projects that require a combination of flexibility and rigidity. With its Lead Free HASL surface finishing, fine line width and spacing, assembly processing, 1oz copper weight, and green solder mask color, this Flexible Rigid Circuit Board is a reliable and high-performance option for a wide range of electronic applications.

Features:

-

Product Name: Rigid Flex PCB

-

Processing: Assembly

-

Surface Treatment: HASL Lead Free , Immersion Gold

-

Size: 9*9cm

-

Outer: Carton Box

-

Surface Finishing: Lead Free HASL

Technical Parameters:

|

Min. Line Width/Spacing

|

0.075mm/0.075mm

|

|

Outer

|

Carton Box

|

|

Max Layer

|

52L

|

|

Stiffener Options

|

Polyimide, FR4, Stainless Steel

|

|

Surface Finishing

|

Lead Free HASL

|

|

Size

|

9*9cm

|

|

Layer Count

|

16 Layers

|

|

Thickness

|

0.6mm

|

|

Components

|

SMD, BGA, DIP, Etc.

|

|

Surface Treatment

|

HASL Lead Free, Immersion Gold

|

Applications:

A Flex Rigid PCB, also known as a Foldable Rigid Circuit Board, offers a versatile solution for various applications due to its unique design combining flexible and rigid areas. The product is designed for specific Processing needs, particularly Assembly processes, making it suitable for a wide range of industries and scenarios.

With a Thickness of 0.6mm, the Flex Rigid PCB strikes a balance between flexibility and durability, making it ideal for applications where space is limited or where bending is required. The compact Size of 9*9cm further enhances its suitability for small-scale electronic devices or systems.

One of the key advantages of the Flex Rigid PCB is its ability to accommodate different Components, including Surface Mount Devices (SMD), Ball Grid Arrays (BGA), Dual In-line Packages (DIP), and more. This versatility in component compatibility makes it a preferred choice for complex electronic assemblies requiring multiple types of components.

With a Layer Count of 16 Layers, the Flex Rigid PCB offers ample space for intricate circuit designs and routing, making it suitable for high-density applications where signal integrity and reliability are crucial.

The product is well-suited for various Product Application Occasions and Scenarios, including but not limited to:

- Aerospace and Defense: The Flex Rigid PCB can be used in aerospace applications where lightweight, compact, and reliable circuit boards are essential for communication, navigation, and control systems.

- Medical Devices: The product is suitable for medical devices that require flexible yet durable circuitry, such as wearable health monitors, diagnostic equipment, and implantable devices.

- Automotive Electronics: In the automotive industry, the Flex Rigid PCB can be utilized in advanced driver-assistance systems, infotainment systems, and engine control units, where space optimization and robust performance are critical.

- Industrial Automation: For industrial automation applications, the Flex Rigid PCB can be integrated into robotics, control systems, and sensors, providing a reliable and compact solution for complex machinery and equipment.

Overall, the Flex Rigid PCB's combination of flexibility, durability, and component compatibility makes it a versatile choice for a wide range of industries and applications, offering reliability and performance in demanding environments.

Customization:

Product Customization Services for the Foldable Rigid Circuit Board:

Solder Mask Colour: Green

Layer Count: 16 Layers

Thickness: 0.6mm

Surface Finishing: Lead Free HASL

Features: Gerber/PCB File Needed

Support and Services:

Rigid Flex PCB product technical support and services include:

- Expert assistance in design and layout of rigid flex circuits

- Guidance on material selection and manufacturing processes

- Testing and quality assurance to ensure reliability

- Troubleshooting and problem-solving for any issues that arise

- Continuous support throughout the product lifecycle

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!