Product Description:

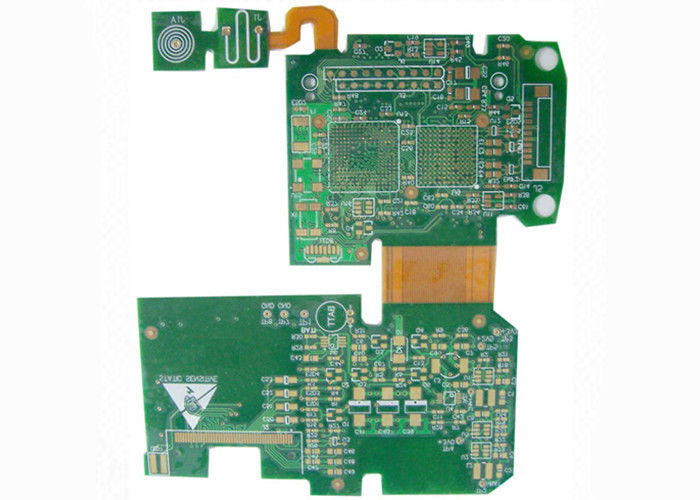

A Rigid Flex PCB, short for Rigid Flexible Printed Circuit Board, is a versatile product that combines the advantages of both rigid and flexible PCBs. Designed to meet the demands of modern electronics, Rigid Flex PCBs offer a unique solution for applications requiring a combination of flexibility and rigidness. One noteworthy product in this category is the Foldable Rigid Circuit Board, which provides added functionality and durability.

Key attributes of the Rigid Flex PCB product include a minimum line space of 8 mil, allowing for precise routing and spacing of components. This feature ensures reliable performance and signal integrity in complex electronic devices. With a maximum layer count of 52L, the Rigid Flex PCB offers ample design flexibility, accommodating intricate circuit layouts and dense component placement.

The solder mask color for this product is green, a standard choice that provides excellent visibility for component placement and soldering processes. The green solder mask also enhances the aesthetic appeal of the PCB, making it a popular option across various industries.

Finished with 1oz of copper, the Rigid Flex PCB boasts optimal conductivity and thermal performance. This copper thickness ensures efficient power distribution and signal transmission, contributing to the overall reliability and efficiency of the circuit board.

One of the standout features of the Rigid Flex PCB is its stiffener options, which include polyimide, FR4, and stainless steel. These stiffener materials provide crucial support and reinforcement to the flexible sections of the PCB, enhancing durability and resistance to mechanical stress. The choice of stiffener material can be tailored to specific application requirements, ensuring that the Rigid Flex PCB meets the desired performance criteria.

In summary, the Rigid Flex PCB product offers a comprehensive solution for applications that demand the unique combination of flexibility and rigidity. With its advanced design features, including a minimum line space of 8 mil, a maximum layer count of 52L, green solder mask color, 1oz finished copper, and multiple stiffener options, the Rigid Flex PCB is a versatile choice for a wide range of electronic devices. Whether used in Foldable Rigid Circuit Boards or other innovative applications, the Rigid Flex PCB delivers reliable performance and durability, making it an ideal choice for modern electronics design.

Features:

-

Product Name: Rigid Flex PCB

-

Surface Finishing: Lead Free HASL

-

Thickness: 0.6mm

-

Features: Gerber/PCB File Needed

-

Min. Line Width/Spacing: 0.075mm/0.075mm

-

Processing: Assembly

Technical Parameters:

|

Components

|

SMD, BGA, DIP, Etc.

|

|

Max Layer

|

52L

|

|

Layer Count

|

16 Layers

|

|

Features

|

Gerber/PCB File Needed

|

|

Surface Finishing

|

Lead Free HASL

|

|

Processing

|

Assembly

|

|

Min. Line Width/Spacing

|

0.075mm/0.075mm

|

|

Stiffener Options

|

Polyimide, FR4, Stainless Steel

|

|

Finished Copper

|

1OZ

|

|

Outer

|

Carton Box

|

Applications:

The Flex Rigid PCB is a versatile and advanced product that caters to a wide range of application occasions and scenarios due to its unique features and capabilities. With the requirement of Gerber/PCB file, this product is ideal for complex electronic devices and systems that demand high precision and reliability.

One of the key attributes of the Flex Rigid PCB is its impressive maximum layer count of 52L, which makes it suitable for intricate and dense circuit designs. Whether it's in aerospace, medical, automotive, or industrial applications, this product can accommodate the complex circuitry requirements of various industries.

Thanks to its flexibility and bendability, the Flex Rigid PCB is perfect for products that need to conform to non-planar surfaces or require a compact form factor. This makes it a preferred choice for wearable technology, IoT devices, and other compact electronic gadgets.

When it comes to packaging and transportation, the Flex Rigid PCB is delivered in a durable carton box, ensuring safe handling and protection during shipping. This packaging solution adds convenience and peace of mind to customers who value product integrity.

The surface treatment options of HASL Lead Free and Immersion Gold enhance the durability and performance of the Flex Rigid PCB, making it suitable for demanding environments and applications where corrosion resistance and signal integrity are crucial.

With a minimum line width and spacing of 0.075mm, the Flex Rigid PCB enables the design and production of highly intricate and compact circuits, pushing the boundaries of electronic engineering and innovation.

Overall, the Flex Rigid PCB is a cutting-edge solution that caters to a diverse range of industries and applications, offering flexibility, reliability, and high performance. Its adaptability to various scenarios and its advanced features make it a top choice for designers and engineers looking to push the boundaries of what's possible with flexible-bendable PCB technology.

Customization:

Product Customization Services for Rigid Flex Printed Wiring Board:

Surface Treatment: HASL Lead Free, Immersion Gold

Outer: Carton Box

Layer Count: 16 Layers

Min. Line Width/Spacing: 0.075mm/0.075mm

Size: 9*9cm

Product Attributes: Rigid Flex Printed Wiring Board, Flexible Rigid Circuit Board, Flex Rigid PCB

Support and Services:

Rigid Flex PCBs offer a unique solution for electronic products that require both rigid and flexible components. Our Product Technical Support team is dedicated to assisting customers with any inquiries regarding the design, manufacturing, and performance of Rigid Flex PCBs. Services include design consultation, material selection guidance, prototyping support, and troubleshooting assistance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!