Product Description:

The evolution of electronics has ushered in the need for high-performance materials to meet the rigorous demands of modern applications. At the forefront of this technological leap is the Ceramic Printed Circuit Board (Ceramic PCB), a board that promises exceptional thermal management, high electrical insulation, and robust mechanical properties. Ceramic PCBs are an ideal substrate for high-power circuits, light-emitting diodes (LEDs), and high-frequency applications, addressing the shortcomings of traditional PCB materials.

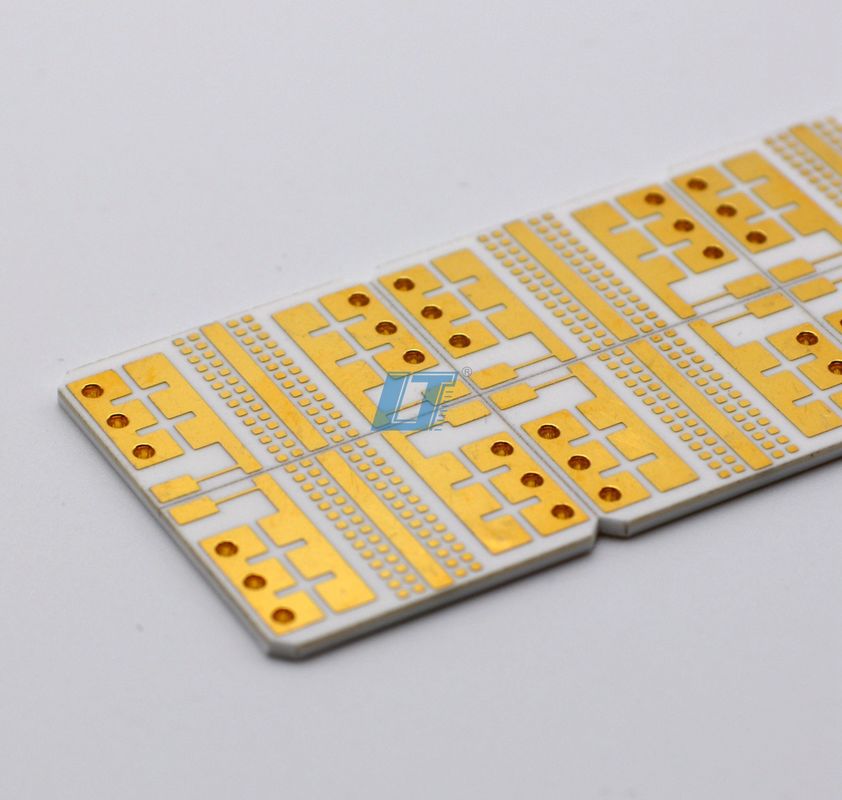

Our range of Ceramic PCBs includes options from 1 to 8 layers, catering to a diverse array of design requirements and complexities. The multi-layering capability allows for greater functionality and denser circuitry within a compact footprint, essential for advanced electronics where space is at a premium. With the ability to maintain a minimum line width/spacing of just 0.1mm, our Ceramic PCBs facilitate intricate designs and high-precision circuits, necessary for sophisticated devices and systems.

One of the key attributes of our Ceramic PCBs is the dielectric constant, which ranges from 6.0 to 10.0. This property is indicative of the material's capacity to store and release electrical energy, which is a critical parameter for high-frequency signal transmission applications. These boards exhibit stable dielectric constants, ensuring signal integrity and consistency in performance across a range of environmental conditions.

In terms of thermal management, our Ceramic PCBs excel with options such as 170W/m·K ALN (Aluminum Nitride) Ceramic PCBs. These boards offer outstanding thermal conductivity, ensuring heat dissipation is efficient and effective, thus preserving the lifespan and reliability of the components mounted on them. This particular characteristic is crucial for high-power LED applications and power converters that generate high levels of heat during operation.

For applications dealing with less extreme thermal management requirements, Al2O3 (Aluminum Oxide) Ceramic PCBs are available. These boards also provide excellent thermal performance, albeit at a lower thermal conductivity level, making them suitable for a broad range of electronic devices. Both ALN and Al2O3 Ceramic PCBs boast impressive thermal stability, withstanding operating temperatures ranging from -50°C to 150°C. This wide temperature range ensures that the Ceramic PCBs can operate reliably in harsh environments without degradation in performance.

Surface technics for our Ceramic PCBs include advanced finishes such as Electroless Nickel Immersion Gold (ENIG) and nickel-palladium gold (GLOD). ENIG provides a flat surface finish that not only aids in the assembly of components but also offers excellent oxidation resistance, ensuring a long-lasting and reliable electrical connection. The nickel-palladium gold finish is employed for its superior wire bondability and resistance to wear, which is particularly useful in high-wear applications.

The incorporation of such advanced finishes complements the inherent properties of the ceramic material, resulting in a PCB that is robust, reliable, and ready for the demands of next-generation electronics. Whether it's for aerospace, medical, automotive, or consumer electronics, our Ceramic PCBs are engineered to deliver performance and durability. With precision manufacturing and stringent quality control measures, we ensure that each Ceramic PCB meets the highest standards of quality and consistency.

In conclusion, our Ceramic PCB product line represents a significant advancement in circuit board technology. With features such as 1-8 layers, a minimum line width/spacing of 0.1mm, high dielectric constants, exceptional thermal management with 170W/m·K ALN Ceramic PCBs and Al2O3 Ceramic PCBs, and robust surface technics like ENIG and GLOD, these PCBs are designed to meet the ever-growing demands of today’s high-performance electronics. They provide engineers and designers with a reliable and efficient platform for developing cutting-edge products that can operate under extreme conditions without compromising on quality or functionality.

Features:

- Product Name: Ceramic PCB Board

- Surface Finished: Immersion Gold, Nickel-Palladium GLOD

- Size: 2mm~200mm

- Thermal Conductivity: 170 W/mK

- Min Line Width/Spacing: 0.1mm

- Surface Technics: ENIG, Nickel-Palladium GLOD

- Keywords:

- Ceramic Dielectric PCB

- High thermal conductivity Ceramic PCBs

- Al2O3 Ceramic PCBs

Technical Parameters:

| Parameter |

Details |

| Thermal Conductivity |

170 W/mK |

| Solder Mask Colour |

Black |

| Surface Technics |

ENIG, nickel-palladium GLOD |

| Pcb Size |

22mm*19mm |

| Operating Temperature |

-50°C To 150°C |

| Service |

One-stop Service / OEM, DFM |

| Material |

Al2O3, ALN |

| Surface Finished |

Immersion Gold, nickel-palladium GLOD |

| Pcb Name |

Immersion Gold Ceramic PCB Board |

| Min Line Width/Spacing |

0.1mm |

Applications:

The Ceramic PCB Board is a highly versatile and durable product designed to meet the demands of various applications that require excellent thermal conductivity, high insulation resistance, and robust performance under extreme conditions. Suitable for operating temperatures ranging from -50°C to 150°C, these boards are perfect for use in environments where thermal management is critical.

With sizes ranging from 2mm to 200mm and the ability to support 1-8 layers, Ceramic PCB Boards can be tailored to fit a wide array of product designs. The surface technics employed, such as Electroless Nickel Immersion Gold (ENIG) and nickel-palladium gold (GLOD), ensure a high-quality finish that is both conductive and resistant to oxidation. As a product type that includes PCB & PCBA OEM and DFM, these boards are designed for seamless integration into a variety of electronic assemblies.

One of the key attributes of the Ceramic PCB Board is the Ceramic Insulated Metal Substrate (CIMS), which provides excellent thermal performance. This makes them an ideal choice for LED lighting applications, power electronics, and high-power transistor modules where heat dissipation is crucial. The use of Direct Bond Copper (DBC) and Direct Plated Copper (DPC) technologies further enhances the thermal management capabilities of these boards, making them suitable for high-power circuits that generate significant amounts of heat.

The advanced manufacturing processes used to create these boards include both Low Temperature Co-fired Ceramic (LTCC) and High Temperature Co-fired Ceramic (HTCC) techniques. LTCC is particularly suited for applications that require a combination of fine feature resolution, embedded components, and a high degree of three-dimensional formability. HTCC, on the other hand, is used for applications that need to withstand extremely high temperatures and harsh conditions.

Overall, the Ceramic PCB Board is an ideal solution for industries such as aerospace, automotive, and industrial electronics where reliability and performance in extreme conditions are non-negotiable. The robust nature of the Ceramic Insulated Metal Substrate, combined with the precision of DBC and DPC technics, makes these boards a preferred choice for engineers and designers seeking high-performance and long-lasting electronic components.

Customization:

Welcome to our Product Customization Services where we specialize in Ceramic Copper Clad PCBs tailored to your specific needs. Whether you are looking for PCB&PCBAOEM,DFM solutions, our expertise is at your disposal.

Our Ceramic PCB Board options are crafted from high-quality materials such as Al2O3 and ALN, ensuring that your product is built on a strong and reliable foundation. With a dielectric constant ranging from 6.0-10.0, our Al2O3 Ceramic PCBs are designed to meet the rigorous demands of your applications.

We understand that versatility is key, which is why we offer a range of layers from 1-8 Layers to accommodate various complexities in circuit design. This flexibility ensures that our Ceramic Board with Copper Clad Laminate can be adapted to suit your precise requirements.

Moreover, our Ceramic PCBs boast an impressive thermal conductivity of up to 170 W/mK, making them an excellent choice for high-performance electronics that require efficient heat dissipation.

Let us help you bring your projects to life with our customizable Ceramic PCB solutions that are engineered for excellence.

Support and Services:

Our Ceramic PCB Board comes with comprehensive technical support and services to ensure your satisfaction and the optimal performance of the product. Our team of expert engineers is available to assist you with any technical inquiries or issues you may encounter. The services include:

Product Consultation: Detailed guidance on selecting the right Ceramic PCB Board for your application, considering factors such as thermal conductivity, board thickness, and layout requirements.

Design Support: Assistance with PCB design, including layout optimization, material selection, and design for manufacturability to ensure the best performance and longevity of your product.

Technical Troubleshooting: Rapid response to any technical problems that arise during the use of our Ceramic PCB Board, including thermal management issues, electrical performance, and mechanical stability.

Assembly Guidance: Advice on the best practices for assembling components onto the Ceramic PCB Board to minimize defects and ensure a high yield rate.

Quality Assurance: Our Ceramic PCB Boards undergo strict quality control procedures to meet high standards of reliability and performance. If you experience any deviation from these standards, our team will work with you to address the issue promptly.

Maintenance Tips: Tips on how to maintain your Ceramic PCB Board to extend its service life, including cleaning recommendations, storage guidelines, and periodic inspection procedures.

Updates and Upgrades: Information on the latest improvements to our Ceramic PCB Boards, as well as upgrade options to enhance the functionality and performance of your existing boards.

We are committed to providing exceptional support and services for our Ceramic PCB Board to ensure that you can leverage its full potential in your applications. If you require additional assistance or have any questions, please reach out to our technical support team for expert help.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!