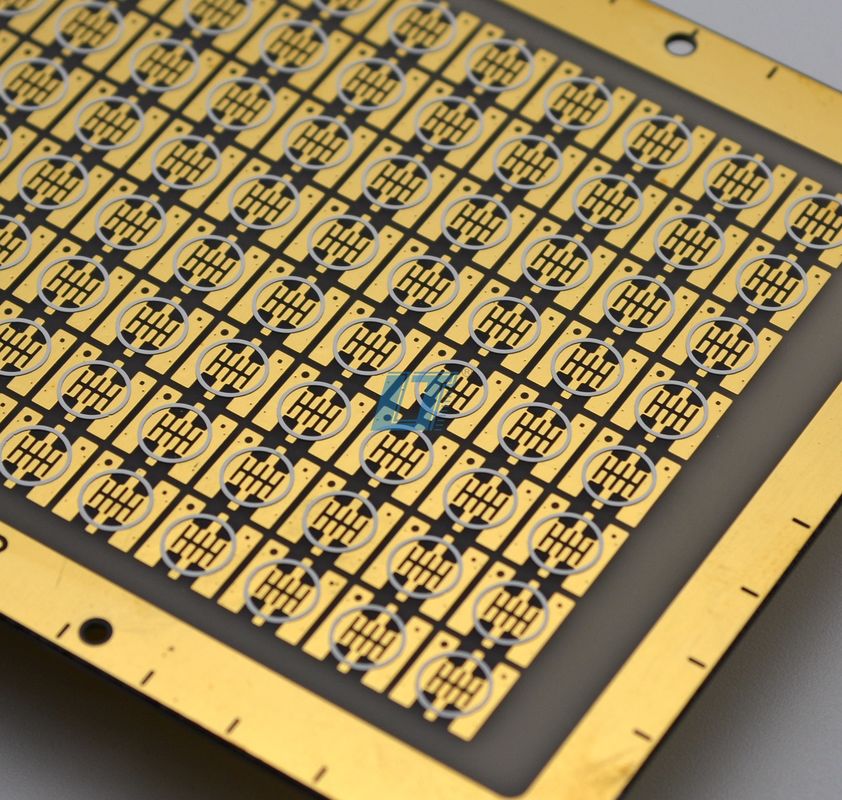

Thermal Conductivity Ceramic PCB Board Immersion Gold ENIG Coated -50u00b0C To 150u00b0C One stop Service

Product Description:

The Ceramic PCB Board stands as a paragon of the latest advancements in the field of electronic substrates, offering an unmatched combination of durability and high performance. Crafted with meticulous attention to detail, this board is designed to cater to the most demanding applications across various industries, from aerospace to medical devices. The essence of this product lies in its ability to operate seamlessly within a wide temperature range, specifically from -50°C to 150°C, making it an ideal choice for environments where thermal stability is paramount.

At the heart of the Ceramic PCB Board's superior performance is its construction material. Utilizing high-grade Aluminum Oxide (Al2O3) and Aluminum Nitride (ALN), these materials are renowned for their excellent thermal conductivity and electrical insulation properties. The Al2O3 variant offers a cost-effective solution while delivering reliable performance, whereas ALN Ceramic PCBs are tailored for applications requiring even higher thermal conductivity and electrical insulation. This choice of materials ensures that the board can withstand the rigors of extreme operating conditions while maintaining optimal functionality.

The Ceramic PCB Board boasts a state-of-the-art surface finish, employing Immersion Gold and nickel-palladium GLOD techniques. These surface finishes not only enhance the board's solderability and wire bondability but also significantly increase its durability. The Immersion Gold finish provides a flat and smooth surface that is critical for the assembly of intricate components, whereas the nickel-palladium GLOD finish adds an extra layer of protection against oxidation, ensuring a long-lasting and reliable interconnection.

The manufacturing process of the Ceramic Printed Circuit Board incorporates the most sophisticated surface technics available in the industry. Employing ENIG (Electroless Nickel Immersion Gold) and nickel-palladium GLOD, these technics ensure an impeccable surface finish that adheres to the highest standards of quality. ENIG provides a consistent layer of gold over the nickel, creating a robust barrier against corrosion and wear, which is indispensable for applications that require a prolonged lifecycle of the product.

Understanding the complexities involved in the design and deployment of advanced electronic systems, the Ceramic PCB Board is complemented by a comprehensive one-stop service. This service is designed to provide customers with end-to-end support, encompassing everything from design, manufacturing to final assembly. OEM (Original Equipment Manufacturer) services are also offered, enabling customization to meet specific requirements. Additionally, DFM (Design for Manufacturability) guidance is provided to ensure that the designs are optimized for manufacturing, thereby reducing costs and improving the overall efficiency of the production process.

One of the unique attributes of the Ceramic PCB Board is its classification as a Ceramic Insulated Metal Substrate (CIMS). This designation highlights the board's exceptional capability to manage thermal dissipation, which is critical for high-power electronic components. The Ceramic Insulated Metal Substrate construction ensures that heat is effectively conducted away from the components, thereby maintaining the integrity and performance of the entire electronic assembly.

In summary, the Ceramic PCB Board is a testament to the relentless pursuit of excellence in the field of electronic substrates. Offering an impressive operating temperature range, robust materials such as Al2O3 and ALN, advanced surface finishes like Immersion Gold, and cutting-edge surface technics such as ENIG, this product is poised to meet the stringent requirements of the modern electronics industry. Supported by a comprehensive one-stop service, including OEM and DFM, the Ceramic PCB Board is not just a component; it's a gateway to unparalleled performance and reliability.

Features:

- Product Name: Ceramic PCB Board

- Product Type: PCB&PCBAOEM, DFM

- Pcb Name: Immersion Gold Ceramic PCB Board

- Service: One-stop Service / OEM, DFM

- Material: Al2O3, ALN

- Solder Mask Colour: Black

- Keyword: Ceramic Printed Circuit Board

- Keyword: Ceramic High Temperature PCB

- Keyword: 170W/m·K ALN Ceramic PCBs

Technical Parameters:

| Parameter |

Specification |

| Thermal Conductivity |

170 W/mK |

| Pcb Name |

Immersion Gold Ceramic PCB Board |

| Product Type |

PCB&PCBAOEM,DFM |

| Min Line Width/Spacing |

0.1mm |

| Solder Mask Colour |

Black |

| Size |

2mm~200mm |

| Surface Finished |

Immersion Gold, nickel-palladium GLOD |

| Material |

Al2O3,ALN |

| Service |

One-stop Service / OEM,DFM |

| Dielectric Constant |

6.0-10.0 |

Applications:

The Immersion Gold Ceramic PCB Board is a high-quality ceramic printed circuit board (Ceramic PCB) designed for a variety of applications where superior thermal management and reliability are essential. This PCB is notable for its surface finish, which includes Immersion Gold and nickel-palladium GLOD, applied using advanced surface technics such as ENIG and nickel-palladium GLOD coating methods. With a compact size of 22mm*19mm, the PCB can be easily integrated into a multitude of devices where space is at a premium.

The impressive thermal conductivity of 170 W/mK makes the Immersion Gold Ceramic PCB Board an ideal choice for use in high power density applications where heat dissipation is a critical concern. This feature ensures that the board can handle high temperatures without compromising performance, making it an excellent Ceramic High Temperature PCB option. As such, it is frequently used in power converters, LED lighting, and high-speed electronics where maintaining a low operational temperature is crucial.

One of the most common scenarios for the Immersion Gold Ceramic PCB Board is in the aerospace industry. The Ceramic High Temperature PCB properties allow it to withstand the extreme conditions found in aerospace applications, including rapid temperature changes and high levels of vibration. Similarly, the automotive industry benefits from the use of ceramic PCBs for engine control units and sensors that require high thermal conductivity and reliability under harsh conditions.

Additionally, the medical industry utilizes these ceramic PCBs for their high reliability and biocompatibility. Medical devices such as scanners and imaging equipment often employ the Immersion Gold Ceramic PCB Board for its ability to operate consistently at elevated temperatures. The telecommunications industry is another area where these PCBs are valued, particularly in high-frequency applications where signal integrity must be maintained despite thermal challenges.

Overall, the Immersion Gold Ceramic PCB Board serves as a robust platform for a variety of high-performance electronics, especially where thermal efficiency and stability are paramount. Its superior surface finish, along with its high thermal conductivity, make it a preferred choice in industries that demand the highest levels of reliability and performance in the face of challenging operating conditions.

Customization:

Our ALN Ceramic PCBs offer a wide range of customization options to meet your specific design needs. With capabilities ranging from 1 to 8 layers, we can accommodate the complexity of your circuit. Our Ceramic Dielectric PCBs feature exceptional thermal conductivity at 170 W/mK, ensuring efficient heat dissipation for high-performance applications.

We provide a sleek black solder mask color for a professional and aesthetic finish on your PCB. The standard PCB size we offer is 22mm*19mm, ideal for compact electronic devices. Moreover, our ALN Ceramic PCBs are designed to endure extreme conditions with an operating temperature range of -50°C to 150°C, guaranteeing reliability and stability in your applications.

Support and Services:

Our Ceramic PCB Board comes with a comprehensive range of technical support and services to ensure the highest level of satisfaction and performance for our customers. Our offerings include:

Product Documentation: We provide detailed documentation, including product specifications, installation guides, and user manuals, to facilitate easy understanding and handling of our Ceramic PCB Board.

Technical Consultation: Our team of experienced engineers is available to provide expert advice on design considerations, material selection, and layout optimization to help you get the most out of your Ceramic PCB Board.

Design Support: We offer design support services to assist with the integration of our Ceramic PCB Board into your specific application. This includes CAD files, reference designs, and technical drawings.

Testing and Quality Assurance: Our Ceramic PCB Boards undergo rigorous testing and quality assurance processes to ensure reliability and performance consistency. We adhere to industry-standard certifications and inspections.

After-Sales Service: We are committed to your satisfaction even after purchase. If you encounter any issues or have questions regarding the product, our after-sales service team is here to provide prompt assistance.

Warranty Services: Our Ceramic PCB Board comes with a standard warranty period. During this time, any defects or malfunctions due to manufacturing errors will be addressed through repair or replacement services.

Training and Workshops: We offer training sessions and workshops to help your team become proficient in the use of Ceramic PCB Boards and stay updated on the latest advancements and best practices.

Our goal is to provide exceptional support and services to ensure that you can leverage the full potential of our Ceramic PCB Board in your applications. For any additional information or support needs, please refer to our contact page or customer service portal.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!