Product Description:

The Ceramic PCB Board is a pinnacle of modern engineering in the realm of printed circuit boards, boasting a fusion of high-performance materials and cutting-edge manufacturing techniques. This board is primarily constructed from premium ceramics such as aluminum oxide (Al2O3) and aluminum nitride (ALN), which are renowned for their exceptional thermal properties and electrical insulation capabilities. The significance of using these materials cannot be overstated as they provide a robust base that ensures the PCB can handle high power densities and extreme temperatures without compromising on performance.

One of the standout features of this Ceramic PCB Board is its impressive thermal conductivity, rated at 170 W/mK. This specification ensures that heat dissipation is managed with utmost efficiency, safeguarding electronic components from the perils of thermal degradation. The high thermal conductivity also plays a pivotal role in extending the lifespan of the PCB by maintaining a controlled thermal environment, which is critical for the long-term reliability and stability of sensitive electronic circuits. Such a feature is indispensable in industries where precision and durability are paramount.

Our Ceramic PCB Board is not just a product but a comprehensive solution, as it comes with the promise of one-stop service. We provide Original Equipment Manufacturer (OEM) and Design for Manufacturability (DFM) services, ensuring that every aspect of the PCB manufacturing process is meticulously catered to your specific needs. Whether it's the initial design phase, material selection, or the final production run, our team of experts will guide you through each step, ensuring a seamless integration of the PCB into your product.

With a size range of 2mm to 200mm, the Ceramic PCB Board is versatile enough to meet diverse application requirements. Whether you need a compact board for a handheld device or a larger substrate for industrial-grade equipment, this PCB can be tailored to fit the form factor and specifications required. This flexibility is a testament to our commitment to providing solutions that are as unique as the challenges our clients face.

The Ceramic PCB Board falls under the umbrella of PCB&PCBA (Printed Circuit Board & Printed Circuit Board Assembly) OEM and DFM services, which means that not only do we manufacture the bare boards, but we also offer full assembly services. This includes sourcing components, surface mount technology (SMT) assembly, through-hole assembly, and rigorous testing processes. Our end-to-end service ensures that the boards are not only fabricated to the highest standards but are also fully equipped to be integrated into the final product.

In the domain of high thermal performance, the Ceramic Insulated Metal Substrate (CIMS) variant of our Ceramic PCB Board is a noteworthy mention. The CIMS technology combines the superior thermal attributes of ceramics with the mechanical strength of a metal base, delivering a PCB that is both thermally efficient and mechanically robust. This hybrid construction is ideal for applications that demand high thermal conductivity without sacrificing structural integrity.

Another innovation in our product lineup is the Ceramic Glass Composite PCB, which is designed for applications requiring a balance of electrical performance, thermal management, and mechanical strength. The composite structure offers an excellent dielectric constant, low loss tangent, and a coefficient of thermal expansion (CTE) that is closely matched to that of the ceramic components, ensuring minimal stress on the solder joints during thermal cycling.

Specifically, our Al2O3 Ceramic PCBs are tailored for industries where electrical insulation and thermal management are critical. The high purity Al2O3 material provides exceptional electrical insulation properties, making these PCBs ideal for high voltage applications, while also delivering impressive thermal conductivity to maintain component temperatures within safe operating limits.

In conclusion, the Ceramic PCB Board represents the synergy of material innovation and manufacturing excellence. Its extraordinary thermal performance, coupled with our comprehensive OEM and DFM services, make it an invaluable asset for any high-reliability application. Whether you are operating in the aerospace, medical, automotive, or consumer electronics industries, our Ceramic PCB Board is engineered to exceed expectations and deliver unparalleled performance.

Features:

- Product Name: Ceramic PCB Board

- Min Line Width/Spacing: 0.1mm

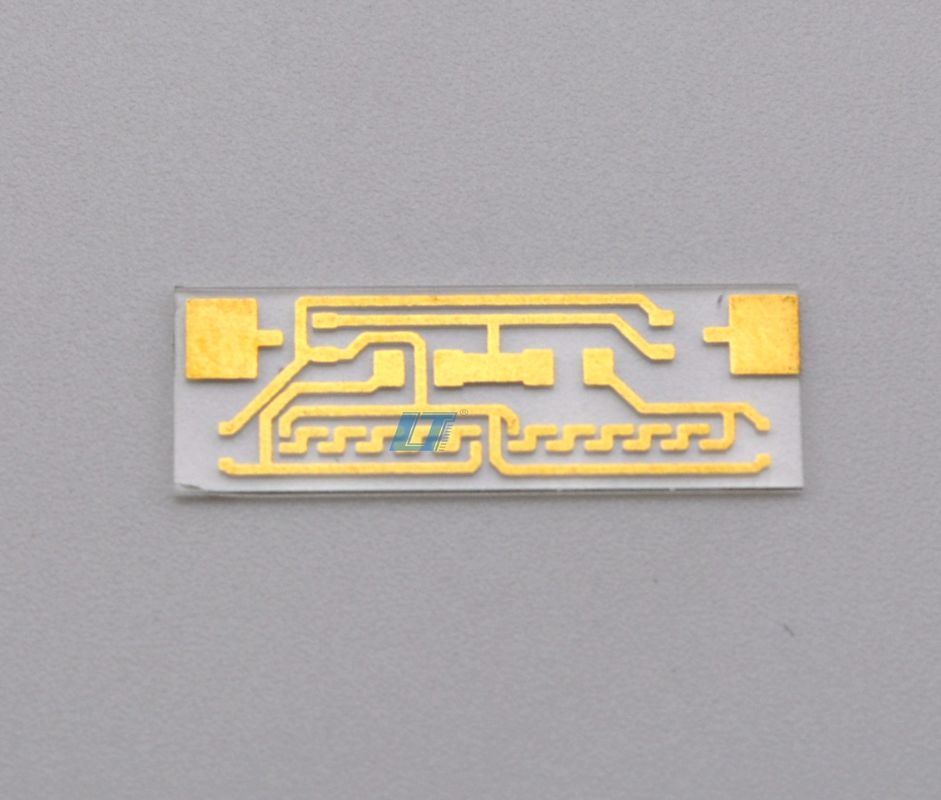

- Pcb Name: Immersion Gold Ceramic PCB Board

- Pcb Size: 22mm*19mm

- Operating Temperature: -50°C To 150°C

- Layers: 1-8 Layers

- Ceramic Board with Copper Clad Laminate

- Ceramic Copper Clad PCB

- 170W/m·K ALN Ceramic PCBs

Technical Parameters:

| Parameter |

Details |

| Min Line Width/Spacing |

0.1mm |

| Surface Technics |

ENIG, nickel-palladium GOLD |

| Product Type |

PCB&PCBAOEM,DFM |

| Pcb Size |

22mm*19mm |

| Material |

Al2O3, ALN |

| Dielectric Constant |

6.0-10.0 |

| Layers |

1-8 Layers |

| Solder Mask Colour |

Black |

| Pcb Name |

Immersion Gold Ceramic PCB Board |

| Service |

One-stop Service / OEM,DFM |

Applications:

The Ceramic PCB Board, crafted from high-quality materials such as Al2O3 (Aluminum Oxide) and ALN (Aluminum Nitride), is a robust platform for a variety of high-performance electronic applications. Its surface technics, which include ENIG (Electroless Nickel Immersion Gold) and nickel-palladium GLOD, provide an exceptional foundation for reliable connectivity and component mounting. The operating temperature range of these PCBs, spanning from -50°C to 150°C, makes them an ideal choice for environments that experience extreme temperature variations.

One of the primary application occasions for the Ceramic PCB Board is in the creation of Ceramic Hybrid PCBs. These boards are often used in power electronic devices where robustness and long-term reliability are of the utmost importance. The hybrid design can be tailored to combine the best attributes of both ceramic and traditional PCB materials, allowing for efficient thermal management and high-density layouts.

Additionally, the Ceramic High Temperature PCB is another scenario where these boards excel. Industries such as aerospace, automotive, and industrial applications, where electronics are exposed to high operating temperatures, will greatly benefit from the use of these PCBs. Their superior heat resistance ensures that the circuit integrity is maintained even under thermal stress, preventing performance degradation over time.

For applications requiring exceptional thermal conductivity, the 170W/m·K ALN Ceramic PCBs stand out. These boards are specially designed for high-power and high-frequency applications, where efficient heat dissipation is critical. The high thermal conductivity of ALN minimizes hot spots and enables the PCB to handle more power, which is particularly beneficial in LED lighting systems, high-speed electronics, and power converters.

The surface finished with Immersion Gold on these Ceramic PCB Boards ensures excellent surface planarity, which is crucial for fine-pitch components or BGA packages. This finish, coupled with the elegant black solder mask colour, not only provides an aesthetically pleasing appearance but also contributes to the PCB's functionality by reducing glare and improving contrast for optical inspection processes.

In summary, the robustness, superior temperature handling, and excellent thermal properties of the Ceramic PCB Board make it an indispensable component in demanding electronic applications. Whether it is utilized in hybrid configurations, high-temperature environments, or high-power systems, these PCBs deliver unmatched performance where traditional PCB materials fall short.

Customization:

Our Ceramic Dielectric PCB customization service offers a range of product attributes tailored to your specific needs. With advanced Surface Technics such as ENIG and nickel-palladium GLOD, we ensure high-quality finishes for your ceramic boards.

The product type falls under PCB&PCBAOEM,DFM, guaranteeing a seamless design and manufacturing process. Our Ceramic Board with Copper Clad Laminate provides exceptional thermal conductivity, rated at 170 W/mK, making it ideal for high-temperature applications.

Choose from a sophisticated black solder mask to match the aesthetic and functional requirements of your project. The standard PCB size we offer is 22mm*19mm, but custom sizes are available to fit your precise specifications.

Whether you are looking for Al2O3 Ceramic PCBs or other ceramic substrates, our product customization services are designed to meet your project's unique demands with precision and reliability.

Support and Services:

Our Ceramic PCB Board is designed with the highest quality standards to ensure durability, performance, and reliability. We are committed to providing comprehensive technical support and services to assist you with any questions or issues you may encounter.

Technical Support:

- Troubleshooting Assistance: Our skilled technicians are available to help diagnose and resolve any problems you may encounter with your Ceramic PCB Board.

- Installation Guidance: We provide detailed instructions and support for the proper installation of your PCB to ensure optimal functionality.

- Product Documentation: Access to a full range of product manuals, technical specifications, and datasheets is provided to help you understand and utilize your Ceramic PCB Board effectively.

Services:

- Repair Services: In the event that your Ceramic PCB Board requires repair, we offer professional services to restore it to its full working condition.

- Replacement Parts: We supply a wide range of replacement parts to help maintain the longevity and performance of your PCB.

- Firmware Updates: Keep your Ceramic PCB Board up-to-date with the latest firmware updates for enhanced performance and new features.

Our support team is dedicated to providing you with the assistance you need to get the most out of your Ceramic PCB Board. Please refer to our product support page for additional resources and information.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!