Product Description:

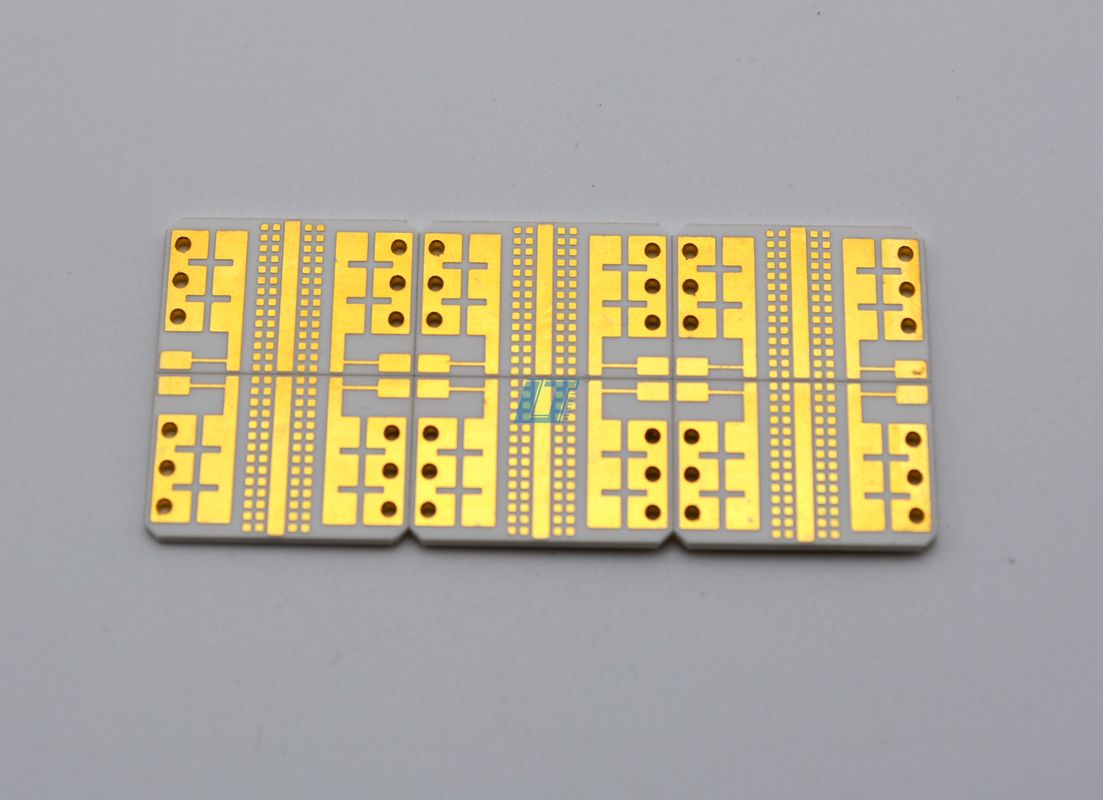

The Immersion Gold Ceramic PCB Board represents a significant leap forward in the field of electronic components, particularly for those applications that demand exceptional thermal management and reliability. Crafted with meticulous precision, this PCB boasts a minimum line width and spacing of 0.1mm, making it an ideal choice for complex circuits that require high-density packaging. The board has been thoughtfully designed with dimensions of 22mm by 19mm, ensuring it can be easily integrated into a wide range of electronic devices without compromising on performance.

One of the standout features of the Immersion Gold Ceramic PCB Board is its extraordinary operating temperature range. It is capable of functioning effectively in extreme conditions, from as low as -50°C to highs reaching 150°C. This impressive range underscores the board's resilience and durability, making it a reliable component in any setting, whether it be in the frigid depths of space or the sweltering confines of industrial machinery.

The Ceramic PCB Board's exceptional performance is largely due to its high thermal conductivity, which stands at a remarkable 170 W/mK. This level of thermal conductivity is essential for high performance and high-power output applications, where managing heat is critical to maintaining function and extending the life of the product. High thermal conductivity Ceramic PCBs, such as this one, dissipate heat more efficiently than traditional PCBs, preventing hot spots and ensuring that all components of the device remain at a safe and stable temperature.

Al2O3 Ceramic PCBs, which refers to Aluminum Oxide Ceramic PCBs, are renowned for their thermal properties and electrical insulation. The material used in the Immersion Gold Ceramic PCB Board is a testament to this reputation, providing not only superior heat dissipation but also excellent dielectric strength. The use of Al2O3 ceramic material ensures that the board is not only capable of withstanding high temperatures but also provides a robust electrical insulation that is critical for the safety and performance of the device.

The surface finish of the Immersion Gold Ceramic PCB Board is another attribute that sets it apart. The application of immersion gold provides a flat surface which is essential for the mounting of various components, especially sophisticated surface-mount devices. This finish not only enhances the solderability of the board but also significantly increases its resistance to oxidation. By preventing corrosion, the board's lifespan is significantly extended, and the reliability of the electrical connections is maintained over time.

High thermal conductivity Ceramic PCBs are increasingly becoming the go-to option for high-stake applications across various industries, including aerospace, automotive, and medical devices. The Immersion Gold Ceramic PCB Board, with its unparalleled thermal performance, compact size, and robust operating temperature range, is poised to meet the demands of these applications. Its cutting-edge design, coupled with the use of high-quality Al2O3 ceramic, ensures optimal performance and reliability.

In conclusion, the Immersion Gold Ceramic PCB Board is a product that embodies the pinnacle of PCB technology. Its high thermal conductivity, exceptional operating temperature range, and the use of Al2O3 Ceramic material make it an ideal solution for any application that requires the utmost in thermal management and reliability. Whether you are an engineer in need of a high-performance board for a demanding project or a manufacturer looking to enhance the durability of your electronic devices, this Ceramic PCB Board is designed to exceed your expectations and deliver unparalleled performance.

Features:

- Product Name: Ceramic PCB Board

- Layers: 1-8 Layers

- Size: 2mm~200mm

- Solder Mask Colour: Black

- Thermal Conductivity: 170 W/mK

- Min Line Width/Spacing: 0.1mm

- Material: Ceramic Substrate PCB

- Type: Ceramic Printed Circuit Board

- Feature: High thermal conductivity Ceramic PCBs

Technical Parameters:

| Parameter |

Specification |

| Surface Finished |

Immersion Gold, nickel-palladium GOLD |

| Material |

Al2O3, ALN |

| Pcb Name |

Immersion Gold Ceramic PCB Board |

| Surface Technics |

ENIG, nickel-palladium GOLD |

| Size |

2mm~200mm |

| Thermal Conductivity |

170 W/mK |

| Product Type |

PCB & PCBA OEM, DFM |

| Min Line Width/Spacing |

0.1mm |

| Service |

One-stop Service / OEM, DFM |

| Solder Mask Colour |

Black |

Applications:

The Ceramic PCB Board, boasting 1-8 layers of high-quality circuitry, stands as a pinnacle of modern electronics design. Its exceptional thermal conductivity of 170 W/mK ensures that even in the most demanding of applications, heat dissipation is handled with unparalleled efficiency. This board is ideally suited for situations where thermal management is crucial, such as in high-power LED lighting systems, automotive electronics, and aerospace components where reliability under thermal stress is paramount.

The surface finish of these PCBs, consisting of Immersion Gold and nickel-palladium GLOD, offers excellent protection against oxidation and ensures a reliable soldering surface. This feature makes the ceramic board with Copper Clad Laminate particularly attractive for use in high-reliability sectors such as medical devices, where a dependable and long-lasting electronic performance is non-negotiable. The elegant surface finish also provides an added aesthetic advantage for visible components in consumer electronics.

As product types that cater to PCB&PCBAOEM and DFM, these boards are designed with customization in mind, fitting seamlessly into a wide range of tailored applications. The adaptability of the Ceramic Hybrid PCB is evident in its ability to serve a diverse set of industries, from telecommunications to the burgeoning field of IoT devices, where precision and performance are key.

With a minimum line width/spacing of 0.1mm, the Ceramic PCB Board offers high-density interconnections, making it a prime choice for intricate designs where space is at a premium. This feature is particularly beneficial in the realms of consumer electronics, where the trend is ever-shifting towards miniaturization, and in military applications, where compact and efficient circuitry can mean the difference between success and failure.

Al2O3 Ceramic PCBs stand out for their electrical insulation properties combined with high thermal conductivity, making them suitable for high voltage applications and environments with significant temperature variances. Their robustness and stability in harsh conditions make them indispensable for industrial controls and energy management systems that require a reliable operation over extended periods.

Overall, the versatility of the Ceramic PCB Board with its superior thermal management, robust surface finish, and high-density interconnect capabilities, makes it an ideal choice for a myriad of applications where durability, efficiency, and precision are essential. From the compact electronics in wearable devices to the critical systems in satellites, this PCB technology is at the forefront of enabling the next generation of electronic innovation.

Customization:

Our Immersion Gold Ceramic PCB Board is a high-quality solution designed to meet your specific needs. Featuring advanced Surface Technics such as ENIG and nickel-palladium GLOD, this board ensures exceptional durability and performance. We are committed to providing a comprehensive One-stop Service / OEM, DFM to streamline your product development process.

The Thermal Conductivity of our PCB is an impressive 170 W/mK, making it an ideal choice for applications requiring Ceramic High Temperature PCB capabilities. With the flexibility of 1-8 Layers , our PCBs can be tailored to fit your specific requirements, whether you're looking for Al2O3 Ceramic PCBs or a Ceramic Hybrid PCB .

Support and Services:

Our Ceramic PCB Board comes with a comprehensive suite of technical support and services designed to ensure the best possible experience for our customers. Our support includes access to our extensive online knowledge base, which contains detailed documentation, FAQs, and troubleshooting tips to assist you in the setup, use, and maintenance of your Ceramic PCB Board.

We also offer a range of services to cater to your specific needs, including professional installation guidance, performance optimization, and technical consultations. Our team of experienced engineers is available to provide support for any technical challenges you may encounter, ensuring that your product performs at its best in various applications.

In addition to these services, we provide regular firmware and software updates to enhance the functionality and security of your Ceramic PCB Board. Our commitment to quality means that we are continuously working to improve our products and services to meet the evolving needs of our customers.

If you require further assistance, our dedicated technical support team is available to address any additional inquiries or concerns you may have. We are devoted to providing you with the highest level of customer service and technical support for your Ceramic PCB Board.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!