Product Description:

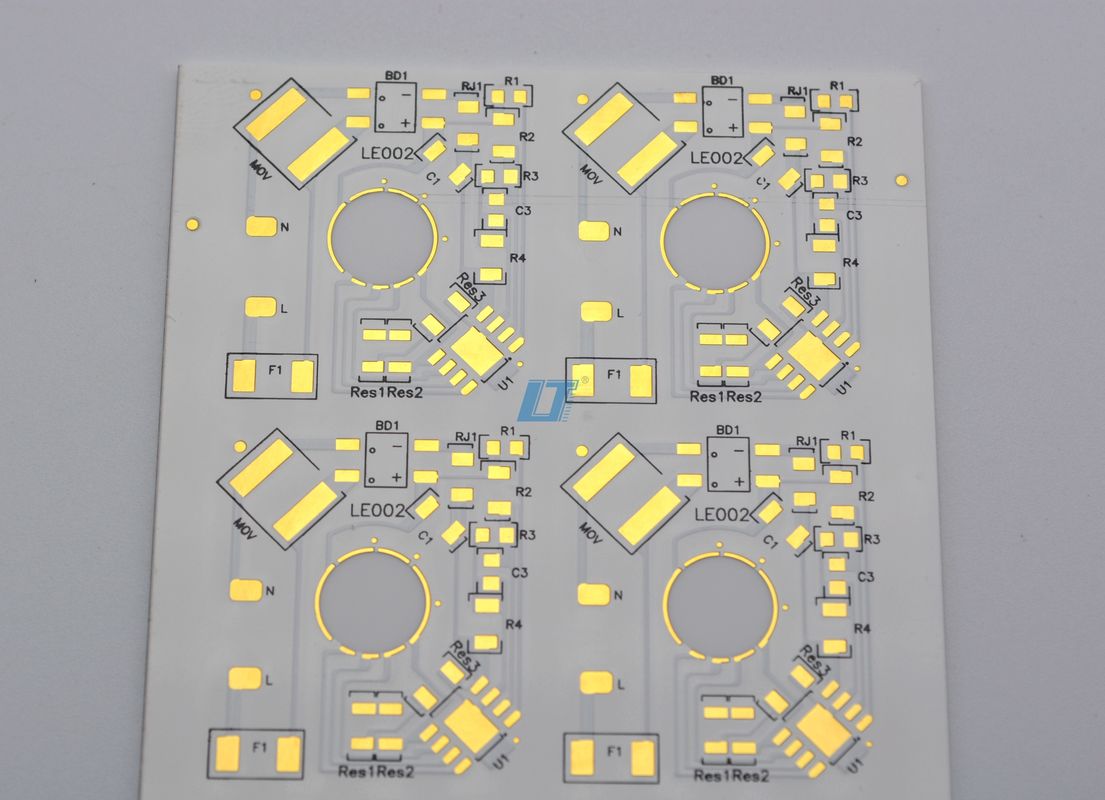

Introducing the pinnacle of precision engineering in the realm of printed circuit boards (PCBs) – our Ceramic PCB Board, crafted with the utmost attention to detail and quality. With dimensions of 22mm by 19mm, this PCB is tailored to meet the compact and space-efficient demands of modern electronic devices. The sleek black solder mask not only adds a layer of protection but also enhances the aesthetic appeal of the board, ensuring that it integrates seamlessly into various applications, from sophisticated aerospace systems to everyday consumer electronics.

Our Ceramic PCB Board is a testament to our commitment to providing a comprehensive one-stop service, including Original Equipment Manufacturer (OEM) capabilities and Design for Manufacturability (DFM) support. We understand that the creation of an electronic device is a journey that involves many steps, and we are dedicated to being your trusted partner every step of the way. From initial design to final production, our expert team is equipped to handle all aspects of PCB manufacturing, ensuring a smooth transition from concept to reality.

The exceptional thermal conductivity of our Ceramic PCB Board, rated at 170 W/mK, stands as a testament to its ability to handle high temperatures with ease. This makes it particularly suitable for applications where heat dissipation is a critical factor. By efficiently conducting heat away from vital components, our PCB helps to maintain optimal performance and extend the lifespan of the electronic device.

Material selection is crucial when it comes to PCBs, and our Ceramic PCB Board is constructed from high-quality Al2O3 and ALN (Aluminum Nitride) ceramics. These materials are chosen for their superior thermal properties, electrical insulation, and mechanical strength. Al2O3, or Aluminum Oxide, provides a cost-effective solution with good thermal conductivity and excellent electrical insulation, while ALN offers even higher thermal conductivity and is ideal for applications that demand the highest performance.

Our product portfolio includes a range of advanced ceramic PCB technologies such as Ceramic Glass Composite PCB, Direct Bonded Copper (DBC), Direct Plated Copper (DPC), Low Temperature Co-fired Ceramic (LTCC), and High Temperature Co-fired Ceramic (HTCC). Each of these technologies brings unique benefits to the table. For example, DBC and DPC techniques are renowned for their ability to create a strong bond between the ceramic substrate and the copper layer, which is essential for high-power circuits. On the other hand, LTCC and HTCC are perfect for applications that require multiple layers of circuits or components to be integrated into a single, compact package.

The versatility of the Ceramic PCB Board is further exemplified by its ability to function as a Ceramic Hybrid PCB. This hybrid approach combines the best of both worlds – the reliability and performance of ceramic materials with the flexibility and cost-effectiveness of conventional PCB materials. As a result, our Ceramic Hybrid PCBs are capable of delivering exceptional performance in the most demanding environments while still being accessible to a wide range of projects and budgets.

In conclusion, our Ceramic PCB Board is a product that embodies innovation, efficiency, and reliability. Whether you are developing high-power electronics, sensitive instrumentation, or any other application that requires the utmost in thermal management and electrical performance, our Ceramic PCB Board is engineered to exceed your expectations. With our comprehensive service offerings, from OEM to DFM, and our expertise in advanced ceramic technologies like DBC, DPC, LTCC, and HTCC, we are equipped to bring your most challenging projects to life with precision and excellence.

Features:

- Product Name: Ceramic PCB Board

- Thermal Conductivity: 170 W/mK

- Surface Finished: Immersion Gold, nickel-palladium GLOD

- Dielectric Constant: 6.0-10.0

- Surface Technics: ENIG, nickel-palladium GLOD

- Service: One-stop Service / OEM, DFM

- Technology Types: DBC (Direct Bond Copper), DPC (Direct Plated Copper), LTCC (Low Temperature Co-fired Ceramic), HTCC (High Temperature Co-fired Ceramic)

- Applications: Ceramic Hybrid PCB

Technical Parameters:

| Parameter |

Description |

| Dielectric Constant |

6.0-10.0 |

| Pcb Name |

Immersion Gold Ceramic PCB Board |

| Product Type |

PCB&PCBAOEM,DFM |

| Thermal Conductivity |

170 W/mK |

| Layers |

1-8 Layers |

| Pcb Size |

22mm*19mm |

| Surface Finished |

Immersion Gold,nickel-palladium GLOD |

| Material |

Al2O3,ALN |

| Solder Mask Colour |

Black |

| Operating Temperature |

-50°C To 150°C |

Applications:

The Ceramic PCB Board, crafted from high-quality materials such as Al2O3 and ALN, is a testament to the advancements in modern electronics. With its surface finished in Immersion Gold or nickel-palladium GLOD, this PCB offers not only a reliable electrical connection but also a premium look and feel. Its exceptional thermal conductivity of 170 W/mK makes it an ideal choice for heat management in high-power applications.

ALN Ceramic PCBs are designed for environments where extreme temperatures are the norm. Operating effectively within a range from -50°C to 150°C, these PCBs are perfectly suited for use in both cold and hot climates, ensuring consistent performance regardless of the external conditions. This makes them an excellent option for aerospace applications, where equipment may be exposed to severe temperature fluctuations.

The high thermal conductivity Ceramic PCBs stand out in applications demanding quick heat dissipation. Power converters, high-power LED lighting, and automotive electronics are just a few examples where the heat generated by components can be efficiently managed, preserving the lifespan and reliability of the devices. The Ceramic Substrate PCB is also a favorite in the field of telecommunications, where maintaining a stable temperature is crucial for signal integrity and overall system performance.

With a dielectric constant ranging between 6.0 and 10.0, the Ceramic PCB Board is also suitable for high-frequency applications. The material properties ensure minimal signal loss and reduce the chances of cross-talk between components, which is essential in RF and microwave circuitry found in satellite communications and advanced radar systems.

In the realm of medical equipment, reliability and precision are paramount. Ceramic Substrate PCBs are not only high-temperature tolerant but also offer excellent electrical insulation properties, making them indispensable in medical devices such as scanners, analyzers, and other diagnostic equipment that require stable and dependable operation.

Industrial applications, such as in the production of semiconductor equipment and photovoltaic devices, also benefit from the robustness of the Ceramic PCB Board. Its ability to withstand thermal and mechanical stress ensures that production lines can operate continuously without the need for frequent maintenance or downtime due to PCB failures.

Customization:

Product Type: PCB&PCBAOEM, DFM – We specialize in custom Ceramic Insulated Metal Substrate boards that offer exceptional thermal management and durability for high-performance applications.

Size: 2mm~200mm – Our versatile size range ensures that we can cater to a variety of design specifications and project requirements.

Material: Al2O3, ALN – Choose from high-quality materials such as Aluminum Oxide (Al2O3) or Aluminum Nitride (ALN) to meet your Ceramic PCB needs.

Solder Mask Colour: Black – Our Ceramic PCBs come with a sleek black solder mask for professional aesthetics and functional benefits.

Pcb Size: 22mm*19mm – The standard PCB size we offer is 22mm by 19mm, which is ideal for a range of compact and efficient ALN Ceramic PCBs.

With our advanced manufacturing capabilities, we deliver top-of-the-line Ceramic Thermal Management PCBs that are tailored to your specific requirements. Trust us for high-quality, reliable, and custom Ceramic PCB Board solutions.

Support and Services:

Our Ceramic PCB Board product comes with comprehensive technical support and services to ensure your satisfaction and the optimal performance of our product. Our support includes a detailed user manual and access to a repository of frequently asked questions and troubleshooting guides. For more in-depth assistance, we offer technical consultations where our experts can provide guidance on product integration, customization, and optimization for your specific application needs.

Additionally, we conduct rigorous quality assurance testing on all our Ceramic PCB Boards to guarantee the highest standards of reliability and durability. Should you encounter any issues with your product, we provide a warranty service that covers defects in materials and workmanship, subject to our warranty terms and conditions.

For maintenance and repairs, our service centers are equipped with advanced tools and staffed by trained professionals who can carry out necessary services to restore your Ceramic PCB Board to its full functionality. Please note that any modifications or repairs not performed by authorized technicians may void the warranty.

We are committed to continuous improvement and welcome customer feedback. Through your input, we can enhance our products and services to better meet your needs. Our goal is to provide you with a seamless and satisfactory experience with our Ceramic PCB Board and support services.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!