Advanced 4 Layer Flex Rigid PCB FR4 Polyimide PET SMD BGA DIP Components 1-8 Flexibility HDI

Product Description:

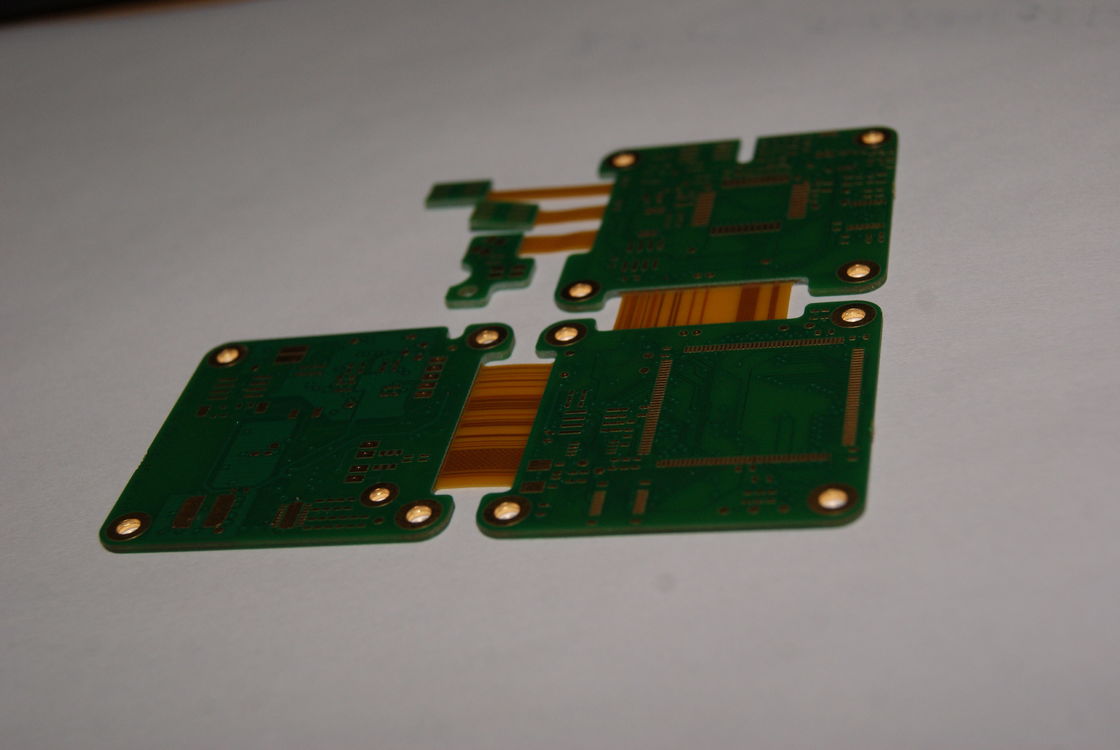

The Rigid Flex PCB combines the best of both worlds in the realm of printed circuit boards, offering the sturdiness of a rigid PCB with the adaptability of a flexible PCB. This innovative product is designed to cater to a wide range of applications where space constraints and durability are key factors. With a dimension of 41.55*131mm, this Flexible Rigid Circuit Board is compact yet capable of accommodating complex circuitry and components, making it an ideal choice for sophisticated electronic devices.

One of the standout attributes of the Rigid Flex PCB is its Bend Radius, which ranges from 0.5-10mm. This feature is integral to the board's flexibility and allows it to be bent and shaped to fit into tight spaces without compromising its functionality or integrity. The ability to bend and shape the board is further enhanced by its flexibility rating, which stands at 1-8 times. This flexibility is a critical aspect of the Bendable Printed Circuit Board, ensuring that it can endure multiple flexing cycles during both the assembly process and throughout the lifecycle of the final product.

When it comes to reliability and performance, the Rigid Flex PCB's Surface Finishing plays a pivotal role. The board is finished with HASL LF (Hot Air Solder Leveling Lead-Free), which is an eco-friendly surface treatment that provides a reliable surface for soldering while being compliant with current environmental regulations. This surface finish not only ensures excellent solderability but also enhances the long-term reliability of the board by preventing oxidation and protecting against corrosion.

The versatility of the Rigid Flex PCB is further demonstrated by its Profiling Punching capabilities. With options such as Routing, V-CUT, and Beveling, the board can be precisely shaped and contoured to meet the specific requirements of various applications. Routing allows for complex shapes and contours, V-CUT creates clean, straight lines that are ideal for creating separate panels within the same board, and Beveling prepares the edges of the PCB for connector insertion or other interface requirements. These profiling techniques ensure that the Rigid Flex PCB can be customized to fit the exact design specifications needed for any project.

As a Flexible-Bendable PCB, this product is engineered to seamlessly integrate the rigid and flex circuits, providing a unified solution that reduces the need for connectors and cables. This integration not only simplifies the overall design but also enhances the electrical performance by reducing the number of interconnection points, which can be potential failure points. The Rigid Flex PCB is particularly useful in applications where reliability is paramount, such as in aerospace, medical devices, and wearable technology, where the board may be subject to repeated movement or flexing.

In summary, the Rigid Flex PCB stands out as a sophisticated, high-performance solution that caters to the evolving needs of modern electronics. With its compact dimensions, flexible bend radius, multiple flexing capabilities, eco-friendly surface finishing, and precise profiling options, it represents a significant advancement in PCB technology. This Bendable Printed Circuit Board is designed not only to meet the stringent demands of today's electronic products but also to pave the way for the innovations of tomorrow.

Features:

- Product Name: Rigid Flex PCB

- Product Type: PCB Assembly

- Components: SMD, BGA, DIP, etc.

- Profiling Punching: Routing, V-CUT, Beveling

- Surface Finishing: HASL LF

- No Of Layers: 4 Layer

- Key Feature: Foldable Rigid Circuit Board

- Key Feature: Flexible Rigid Circuit Board

- Key Feature: Bendable Printed Circuit Board

Technical Parameters:

| Technical Parameter |

Specification |

| Sanforized |

Local High Density, Back Drill |

| Surface Finishing |

HASL LF |

| No Of Layers |

4 Layer |

| Bend Radius |

0.5-10mm |

| Flexibility |

1-8 Times |

| Pcb Layer |

1-28layers |

| Minimum Trace/Space |

0.1mm |

| Max Layer |

52L |

| Hole Position Deviation |

±0.05mm |

| Product Type |

PCB Assembly |

Applications:

The Rigid Flex PCB, a marvel of modern electronics, is a product type that belongs to the PCB Assembly category, exhibiting unparalleled versatility and reliability. This product integrates the best attributes of rigid and flexible circuit boards, resulting in a superior Rigid Flex Printed Wiring Board that caters to numerous application occasions and scenarios. With capabilities ranging from 1 to 28 layers, it is engineered to meet the most demanding requirements of today's intricate electronic devices.

One of the defining features of the Rigid Flex PCB is its local high-density attribute, which allows it to support complex circuits in a compact form factor, making it ideal for high-precision applications. This is particularly beneficial in industries where space is at a premium, such as in aerospace or medical devices. The precision of the Rigid Flex PCB is further enhanced by its hole position deviation tolerance of ±0.05mm, ensuring exact alignment and connection reliability in multi-layer configurations.

The back drill technique employed in the Rigid Flex PCB manufacturing process eliminates redundant via stubs, improving signal integrity and performance in high-speed applications. This makes these boards especially suitable for communications equipment, military systems, and computer peripherals that require robust and high-speed signal transmission.

To ensure the longevity and functionality of the Rigid Flex Printed Circuit Boards, various surface treatments are available, including ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservatives), Immersion Gold, Tin, and Silver. These treatments not only protect the PCB from corrosion but also enhance solderability and electrical performance. Therefore, whether it's a consumer wearable device or a critical automotive control system, the Rigid Flex PCB stands up to the environmental challenges with unmatched durability.

The application scenarios for Rigid Flex PCBs are diverse. They seamlessly integrate into the compact and mechanically complex designs of modern smartphones, cameras, and wearable technology. Their unique construction allows them to bend during use or installation, accommodating unconventional shapes and movements within the product design. Additionally, in industries such as military and aerospace, the Rigid Flex Printed Wiring Board is prized for its ability to withstand extreme conditions while maintaining consistent performance.

In summary, the Rigid Flex PCB product's adaptability to a variety of treatments, precision in hole positioning, and the capability to be configured into multiple layers, make it an integral component in a wide array of electronic applications. Its suitability for high-density, high-reliability, and demanding environments ensures that it remains a cornerstone in the evolution of compact, efficient, and durable electronic assemblies.

Customization:

Our Flex Rigid PCB product line offers comprehensive Product Customization Services to meet your specific design requirements. With a Surface Finishing of HASL LF, our boards ensure reliable solderability and a long shelf life. The Rigid Flex Printed Wiring Board can be customized to your required Dimension, with a standard size of 41.55*131mm.

When it comes to Material selection, we provide options such as FR4, Polyimide, and PET to cater to different applications and flexibilities. Our Bendable Rigid Printed Wiring Board can be designed with anywhere from 1 to 28 layers (Pcb Layer), allowing for complex circuitry and multi-functionality in a compact package.

We understand the importance of precision, which is why we offer a Minimum Trace/Space of 0.1mm, ensuring high-density interconnects and superior electrical performance for your Rigid Flex PCB needs.

Support and Services:

Rigid Flex PCBs combine the durability of rigid printed circuit boards with the flexibility of flex circuits, ensuring that your product can withstand the stresses of both static and dynamic flexing applications. Our technical support and services for Rigid Flex PCB products are designed to provide you with the highest level of assistance from the initial design phase to the final production stage.

Our support begins with design consultation, where our experts work closely with you to ensure that your Rigid Flex PCB design is optimized for manufacturing and performance. We offer guidance on material selection, layer stack-up, trace routing, and flex-to-rigid transitions, among other design considerations.

Once your design is finalized, we provide comprehensive prototyping services. This allows you to test and validate your Rigid Flex PCBs before moving into full-scale production. Our prototyping service ensures that any potential issues are identified and corrected early in the development process.

For manufacturing support, we employ advanced fabrication techniques to meet your requirements for complex geometries and high-density interconnects. We ensure that every Rigid Flex PCB is manufactured to the highest quality standards, with rigorous testing and quality control measures in place.

Our post-production services include assembly support, where we can offer assistance in integrating your Rigid Flex PCBs with other components. We also provide guidance on proper handling and installation to maximize the lifespan and reliability of your product.

In the event that you encounter any challenges with your Rigid Flex PCBs, our responsive technical support team is ready to assist you with troubleshooting and resolving any issues quickly and efficiently. We are committed to providing outstanding customer service and ensuring your complete satisfaction with our products and services.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!