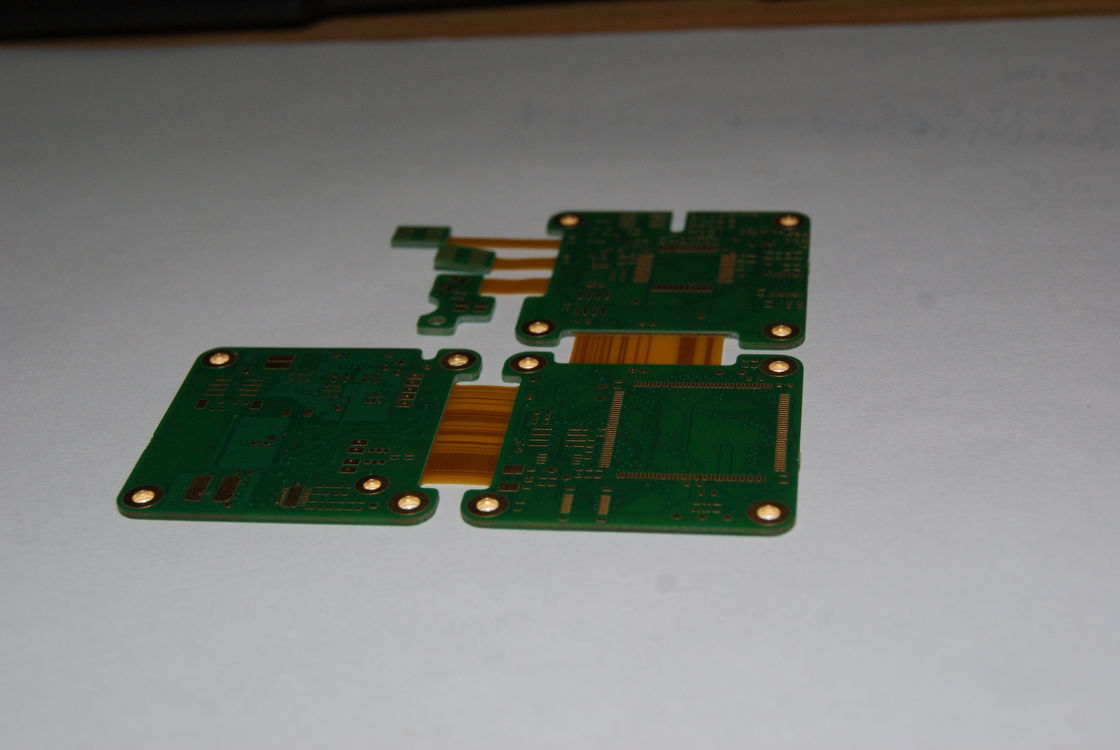

Polyimide FR4 Density PCB Assembly 28-Layer Rigid Flex Circuit Board with SMD Components

Product Description:

The Rigid Flex PCB, with a sophisticated construction of a 4 Layer board, represents a pinnacle of modern circuit board technology that blends the best of both worlds in terms of flexibility and rigidity. This innovative product stands out as a Flexible Stiff Circuit Board, offering unparalleled adaptability and robustness for a vast array of electronic applications. With meticulous attention to detail, this board is engineered to meet the highest standards of quality and performance.

One of the hallmark treatments of the Rigid Flex PCB is its variety of surface finishes which includes ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservatives), Immersion Gold, Tin, and Silver. Each of these treatments is designed to enhance the board's longevity, reliability, and solderability, ensuring that your product performs consistently over time. The choice of finish allows for flexibility in the application, with ENIG being particularly useful for its excellent surface planarity, OSP for its eco-friendly nature, Immersion Gold for its superior conductivity, Tin for its cost-efficiency, and Silver for its excellent thermal and electrical properties.

The precise dimensions of the Rigid Flex PCB are 41.55*131mm, meticulously crafted to fit a wide range of devices while maintaining a compact form factor. This size is particularly suitable for sophisticated electronic devices where space is at a premium, and efficient use of every millimeter is crucial. Whether it's for consumer electronics, medical devices, or aerospace technology, the carefully calculated dimensions ensure a perfect fit and optimal performance.

When it comes to components, the Rigid Flex PCB is designed to support a variety of electronic components including SMD (Surface Mount Devices), BGA (Ball Grid Array), DIP (Dual In-line Package), and more. This versatility allows for a diverse range of components to be mounted on the circuit board, making it an ideal choice for complex electronic assemblies. The board's design also takes into account the evolving nature of electronic components, ensuring compatibility with both current and future technologies.

Accuracy is of the utmost importance in PCB manufacturing, and our Rigid Flex PCB boasts a remarkable Hole Position Deviation of ±0.05mm. This level of precision is critical when dealing with advanced electronic components, particularly those with fine pitch such as BGA. Such precision ensures that each component is perfectly aligned with the board's layout, leading to a reliable electrical connection and reducing the risk of manufacturing defects.

The Rigid Flex PCB is not just a Foldable Rigid Circuit Board; it's a testament to the advancements in PCB technology. Its ability to bend and fold without compromising the integrity of the circuit makes it an ideal solution for dynamic applications where movement and flexibility are necessary. It brings forth a solution that is both mechanically stable and adaptable, capable of sustaining repeated flexing without failure. This characteristic opens up new possibilities for innovative product designs that were previously constrained by the rigidity of traditional PCBs.

In essence, the Rigid Flex PCB is a versatile, high-quality circuit board solution that finds its place in numerous high-tech industries. With its combination of a Flexible Stiff Circuit Board design, advanced component compatibility, precise hole alignment, and a variety of surface treatments, this product is truly at the forefront of PCB technology. It is designed for those who seek excellence in their electronic products, providing a foundation that enables complex functionalities in a reliable and efficient manner.

Features:

- Product Name: Rigid Flex PCB

- Max Layer: 52L

- Dimension: 41.55*131mm

- Minimum Trace/Space: 0.1mm

- Pcb Layer: 1-28 layers

- No Of Layers: 4 Layer

- Flexible Rigid Circuit Board

- Bendable Printed Circuit Board

- Flex-Rigid Printed Circuit Board

Technical Parameters:

| Attribute |

Details |

| Max Layer |

52L |

| Surface Finishing |

HASL LF |

| Profiling Punching |

Routing, V-CUT, Beveling |

| Product Type |

PCB Assembly |

| Bend Radius |

0.5-10mm |

| Material |

FR4, Polyimide, PET |

| Sanforized |

Local High Density, Back Drill |

| No Of Layers |

4 Layer |

| Treatment |

ENIG/OSP/Immersion Gold/Tin/Silver |

| Dimension |

41.55*131mm |

Applications:

The 4 Layer Flex-Rigid Printed Circuit Board (PCB) is a state-of-the-art solution that marries the flexibility of traditional flexible circuits with the rigidity and robustness of standard PCBs. This type of board is specifically designed to provide exceptional versatility and reliability in a variety of applications and scenarios. With a precise hole position deviation of ±0.05mm and the ability to reach up to 52 layers, the Flex-Rigid PCB is suitable for complex and high-density electronic assemblies.

One of the most significant applications for the 4 Layer Flex-Rigid Printed Circuit Board is in the field of aerospace and aviation. These environments demand electronics that can withstand extreme conditions while maintaining high performance. The Flex-Rigid PCB's combination of FR4, Polyimide, and PET materials ensures that it can endure the stresses of flight, including vibration, temperature fluctuations, and constant movement, making it an ideal choice for cockpit instrumentation, onboard systems, and satellite technology.

In the medical industry, reliability and precision are paramount. The Flex-Rigid Printed Circuit Board can be found in medical devices such as wearable health monitors, advanced imaging systems, and even in surgical instruments where the Flexible Stiff Circuit Board's adaptability to form and space constraints is invaluable. With surface treatments like ENIG, OSP, Immersion Gold/Tin/Silver, these boards offer excellent connectivity and longevity, crucial for life-saving medical equipment.

Consumer electronics is another realm where the Flex-Rigid PCB shines. As devices become smaller, yet more powerful, the need for compact, multi-layered circuit solutions grows. The 4 Layer Flex-Rigid PCB fits perfectly into smartphones, tablets, and laptops, providing the necessary electrical performance while conforming to the sleek, ergonomic designs that consumers demand. Moreover, the board's ability to fold and flex allows for innovative product designs that were previously not possible.

Industrial and automotive sectors also benefit from the Flex-Rigid Printed Circuit Board's robustness and adaptability. In an automotive context, these boards are used within control systems, GPS units, and sensors, where they need to endure the rigors of the road such as shock, moisture, and chemical exposure. Industrial applications include robotics, automation machinery, and control panels, all of which require the durability and high layer count that the Flex-Rigid PCB can provide.

In summary, the 4 Layer Flex-Rigid Printed Circuit Board is a versatile and dependable solution suitable for an array of applications. Its precision, material quality, and treatment options make it an excellent choice for any scenario requiring a Flexible Stiff Circuit Board that can withstand demanding environments while maintaining top performance.

Customization:

Our Flex-Rigid Printed Circuit Board (PCB) offers customization to meet your specific design needs. With flexibility options ranging from 1-8 times, our Rigid Flex PCB is designed to accommodate the necessary bending and movement for your application.

Enjoy enhanced electrical performance with our local high-density sanforization and precision back drill technology, ensuring your Flex-Rigid PCB operates at the highest level of reliability and functionality.

Custom dimensions are available, and for this product, we offer a size of 41.55*131mm, perfectly tailored to fit your requirements.

The maximum layer count for our boards reaches up to 52L, allowing for complex and multi-functional circuit designs. This particular configuration comes with a 4 Layer structure, providing a balance between performance and cost-effectiveness.

Choose our Flex Rigid PCB services for a product that delivers on both quality and customization, ensuring your project's success with a board that's designed to your exact specifications.

Support and Services:

Our Rigid Flex PCB product is backed by comprehensive technical support and services to ensure your success from design to implementation. Our team of experienced engineers is available to assist with any technical queries or challenges you may encounter. We offer design support to help optimize your Rigid Flex PCB for performance and manufacturability, as well as troubleshooting assistance to address any issues during product integration.

In addition to our expert technical guidance, we provide a suite of services aimed at delivering the highest level of product performance. This includes rigorous quality testing, adherence to industry standards, and a commitment to continuous improvement. We also offer customization options to meet your specific application requirements, ensuring your Rigid Flex PCB solution is perfectly tailored to your needs.

To further support your project, we provide documentation and resources that cover best practices, installation procedures, and maintenance tips to extend the lifespan and reliability of your Rigid Flex PCB. With our dedicated technical support and services, you can confidently deploy our Rigid Flex PCBs in your most critical applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!