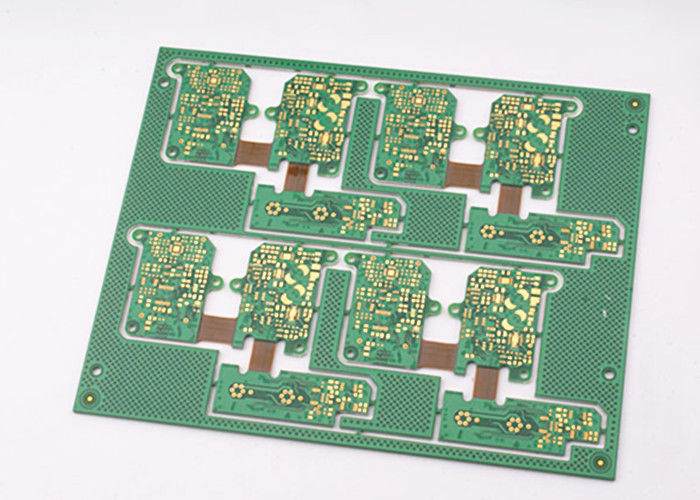

Flexibility 4 Layer Rigid Flex PCB ENIG/OSP/Immersion Gold/Tin/Silver Treatment 0.1mm Trace/Space

Product Description:

The Rigid Flex PCB product represents a remarkable technological advancement in the field of electronic components, providing a hybrid construction that combines the best attributes of both rigid and flexible circuit technologies. This innovative solution is designed to cater to the demanding requirements of various high-end electronic applications, where space, weight, and reliability are crucial considerations. The Rigid Flex PCB is an embodiment of versatility and durability, offering a seamless transition between rigid and flexible areas, which allows for a more compact and reliable product design.

The core material used in the construction of these circuit boards is a combination of FR4, Polyimide, and PET. FR4 is a widely accepted fiberglass-reinforced epoxy laminate that offers excellent dimensional stability and mechanical strength, making it suitable for the rigid sections of the PCB. Polyimide, known for its flexibility and high-temperature resistance, is employed in the flexible areas, providing the necessary bendable characteristics without compromising on performance. PET, a thermoplastic polymer, is also used due to its flexibility, durability, and cost-effectiveness. This triad of materials ensures that the Rigid Flex PCB is not only robust but also can withstand the rigors of various environmental conditions.

As a Bendable Printed Circuit Board, the Rigid Flex PCB guarantees a flexibility range of 1-8 times. This level of flexibility makes it an ideal choice for applications that require repeated movement or bending, such as in foldable devices or dynamic flexing environments. The ability to bend without causing damage to the circuitry is a critical aspect of the design, and this product meets that requirement with ease, ensuring long-term reliability and functionality.

The precision involved in the manufacturing of the Rigid Flex PCB is reflected in its hole position deviation specification, which stands at a remarkable ±0.05mm. Such high precision ensures that components and vias are placed with exceptional accuracy, resulting in a significant reduction in signal losses and electrical noise. This meticulous attention to detail is crucial for high-speed signal applications, where even the slightest deviation could disrupt overall performance.

With a dimension of 41.55*131mm, the Flexible Rigid Circuit Board is engineered to fit into a diverse range of product configurations. This specific size allows for optimal utilization of space within the device, enabling designers to incorporate more features into smaller form factors. The compact dimensions coupled with the hybrid design approach make it possible to develop sophisticated electronics that are lighter and thinner without sacrificing functionality.

The product type for this offering is PCB Assembly, which means that the Rigid Flex PCB comes ready for the integration of various electronic components. The ability to combine multiple rigid and flexible boards into a single assembly reduces the need for connectors and cables, which in turn minimizes points of failure and enhances the overall structural integrity of the device. This integration simplifies the assembly process, reduces the overall cost, and improves the performance of the final product.

In summary, the Flex-Rigid Printed Circuit Board stands as a testament to the ingenuity and progress in PCB design and manufacturing. Its unique combination of materials, precision, flexibility, and compact design makes it an indispensable component in modern electronic devices. Whether it is for consumer electronics, medical devices, military equipment, or aerospace applications, the Rigid Flex PCB is engineered to meet the highest standards of performance and reliability, making it a preferred choice for innovators and manufacturers alike.

Features:

- Product Name: Rigid Flex PCB

- Surface Finishing: HASL LF

- Profiling Punching: Routing, V-CUT, Beveling

- No Of Layers: 4 Layer

- Sanforized: Local High Density, Back Drill

- Max Layer: 52L

- Flexible Stiff Circuit Board

- Flex-Rigid Printed Circuit Board

- Rigid Flexible Printed Circuit Board

Technical Parameters:

| Parameter |

Specification |

| Bend Radius |

0.5-10mm |

| Hole Position Deviation |

±0.05mm |

| Dimension |

41.55*131mm |

| Treatment |

ENIG/OSP/Immersion Gold/Tin/Silver |

| Sanforized |

Local High Density, Back Drill |

| Max Layer |

52L |

| Material |

FR4, Polyimide, PET |

| Surface Finishing |

HASL LF |

| No Of Layers |

4 Layer |

| Profiling Punching |

Routing, V-CUT, Beveling |

Applications:

The Rigid Flex Printed Wiring Board, combining the best of both rigid boards and flexible circuits, has become an essential component in modern electronics. The product is designed to be flexed from 1-8 times which allows it to be used in applications where the product must conform to certain shapes or be capable of withstanding movement and bending. This ability to flex makes it perfect for use in complex, three-dimensional product designs.

With a maximum layer count of up to 52 layers, the Rigid Flex PCB can accommodate a dense population of components, making it suitable for highly sophisticated electronic assemblies. This high layer count is indicative of the product's versatility and adaptability to various complex applications. Furthermore, the product is available in configurations from 1 to 28 layers for the PCB, providing a wide range of flexibility and rigidity as needed by the application.

The surface treatment options for the Rigid Flex Printed Wiring Board include ENIG, OSP, Immersion Gold, Tin, and Silver. These treatments ensure reliable solderability, protection against oxidation, and a robust interface for component attachment. Such a variety of treatments ensures that the product can be tailored to meet the specific environmental and operational requirements of the application it is used in.

With a bend radius ranging from 0.5 to 10mm, the Flexible Rigid Circuit Board can be designed to fit into tight spaces and wrap around edges or corners, making it an ideal solution for compact and portable electronic devices. The small bend radius also helps in minimizing stress on the electrical connections during bending, ensuring a longer lifespan for the application.

Applications for the Rigid Flex PCB are extensive and diverse. They are commonly found in the aerospace industry where the combination of lightweight, flexibility, and high reliability is crucial. Medical devices also benefit from Rigid Flex PCBs due to their ability to conform to the ergonomic shapes of wearable technology and the stringent reliability requirements. Consumer electronics, such as smartphones and cameras, utilize Rigid Flex Printed Wiring Boards to maximize space and enhance durability. In the automotive sector, the Rigid Flex PCBs are used for their ability to withstand harsh environments and vibrations, making them perfect for in-vehicle systems and sensors.

In conclusion, the Rigid Flex Printed Wiring Board is a highly adaptable and durable solution suitable for a myriad of applications where space, flexibility, and reliability are paramount. Its customizable layer count, surface treatments, and bend radius make it an invaluable component in the fields of aerospace, medical, consumer electronics, and automotive industries, among others.

Customization:

Our Flex Rigid PCB product offers an array of customization services to meet your specific design requirements. We provide high-quality materials such as FR4, Polyimide, and PET, ensuring that your Rigid Flexible Printed Circuit Board is both durable and reliable. With the option for a 4 Layer construction, we cater to complex circuit designs without compromising on flexibility or rigidity.

As a leading PCB Assembly service provider, we understand the importance of precision. Therefore, our customization services include a strict Hole Position Deviation tolerance of ±0.05mm, guaranteeing exacting standards for your Flexible-Bendable PCB projects. Our advanced manufacturing processes ensure that each PCB is crafted with meticulous attention to detail.

To enhance the performance and longevity of your Flex Rigid PCB, our surface finishing includes HASL LF (Lead-Free Hot Air Solder Leveling), which offers superior solderability and resistance against corrosion, making it an ideal choice for environmentally conscious applications requiring a Rigid Flexible Printed Circuit Board.

Support and Services:

Our Rigid Flex PCB products are supported by a comprehensive technical support and service package to ensure the highest level of performance and reliability. Our expert team is dedicated to providing you with the following services:

Pre-Sales Consultation: Our knowledgeable staff is available to help you select the right Rigid Flex PCB solution for your specific application needs. We provide advice on design, material selection, and cost optimization to ensure that you get the most value out of our products.

Design Support: We offer design support services to assist you in creating a Rigid Flex PCB that meets your technical requirements. Our team can provide guidance on layout, stack-up, impedance control, and more to help you optimize your design for manufacturing.

Prototyping: To help you validate your design before full-scale production, we provide rapid prototyping services. This allows you to test the functionality and reliability of your Rigid Flex PCB design, ensuring that any potential issues are addressed early in the development process.

Manufacturing Support: Our state-of-the-art manufacturing facilities are equipped to produce high-quality Rigid Flex PCBs with precision and efficiency. We support you through the entire manufacturing process, from material procurement to final assembly.

Quality Assurance: We are committed to delivering products that meet the highest quality standards. Our rigorous quality assurance process includes inspection and testing to ensure that each Rigid Flex PCB adheres to your specifications and industry standards.

Technical Documentation: We provide comprehensive technical documentation for our Rigid Flex PCB products, including detailed specifications, user manuals, and maintenance guides to assist you in the proper handling and use of our products.

After-Sales Support: Our relationship with our customers does not end with a sale. We offer after-sales support to address any concerns or issues that may arise during the use of our Rigid Flex PCBs. Our technical support team is always ready to provide assistance to ensure your continued satisfaction.

Training: To ensure that you are able to fully leverage the capabilities of our Rigid Flex PCBs, we offer training sessions covering various aspects, including installation, operation, and maintenance.

We are dedicated to providing you with the support and services you need to succeed with our Rigid Flex PCB products. Our team is here to assist you at every step, from initial inquiry to post-purchase support.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!