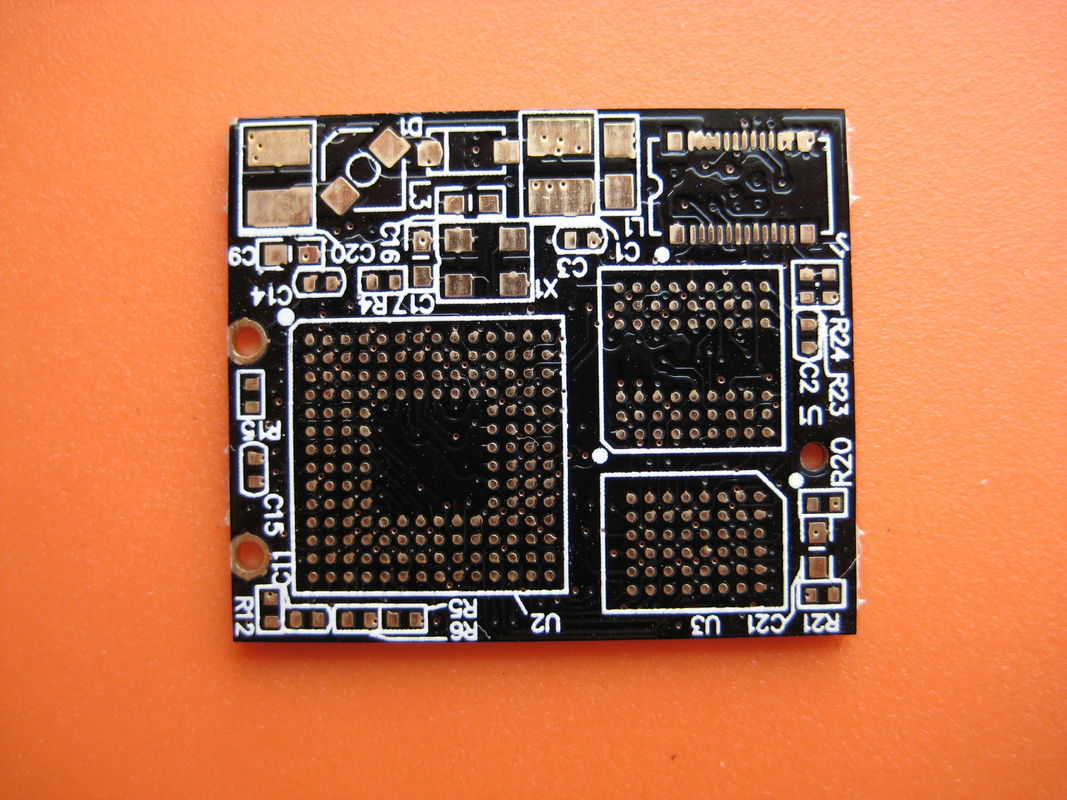

6-32L HDI PCB Board With 10 1 Aspect Ratio 100%E-Testing 0.2-6.00mm Half Hole Bga Feature

Product Description:

The 4L 1+N+1 HDI Boards represent the pinnacle of high-density PCB design, incorporating cutting-edge technology to meet the most rigorous demands of modern electronics. As an industry leader in the production of HDI Printed Circuit Boards, we are proud to introduce a product that not only exemplifies exceptional engineering but also meets special requirements, such as being tailored to accommodate a lamp socket. This specialization ensures that our HDI PCBs are versatile and can be integrated into a variety of applications where lighting components are essential.

Constructed from the high-quality raw material FR4 IT180, these boards offer outstanding thermal resistance and mechanical strength, ensuring they perform reliably under intense operational conditions. The FR4 IT180 material is renowned for its excellent dielectric properties, which makes it the substrate of choice for ensuring signal integrity in high-speed designs like DDR4 PCBs. Our 4L 1+N+1 HDI Boards are particularly suitable for use in environments where DDR4 memory is employed, providing the stability and performance required for high-speed data transmission.

The intricate design of these High Density PCBs allows for a staggering aspect ratio of 10:1. This impressive feature signifies the board's capability to accommodate finer lines and spaces, smaller vias, and capture pads, thus enabling a higher concentration of component placement. The aspect ratio is a critical parameter in HDI board manufacturing, and achieving a 10:1 ratio is a testament to our advanced fabrication processes and our commitment to delivering products that lead the industry in density and complexity.

Our 4L 1+N+1 HDI Boards are not only exemplary in their design but also in their versatility. The board layer count ranges from 6 to 32 layers, allowing for a vast array of configurations to suit various applications and complexities. Whether it's for a simple device or a complex multi-layered system, our HDI PCBs can be customized to meet the specific needs of your project. The multi-layer configuration is particularly beneficial for high-speed applications such as DDR4 PCBs, where signal integrity and layer isolation are critical for performance.

Featuring the 1+N+1 HDI structure, these boards are at the forefront of HDI technology. This structure indicates one layer of high-density interconnection above and below the core layer, providing a platform for a significant number of I/Os in a small form factor. This design is particularly advantageous for applications requiring high-performance interconnects with a reduced footprint, making it ideal for portable and miniaturized electronic devices.

Our commitment to quality and precision in the manufacturing of the 4L 1+N+1 HDI Boards is unwavering. We utilize state-of-the-art equipment and techniques to ensure that every board meets the highest standards of quality and reliability. Each board undergoes rigorous testing and inspection to guarantee that it performs to its specifications, which is especially crucial for high-speed and high-frequency applications such as DDR4 PCBs.

In conclusion, the 4L 1+N+1 HDI Boards are an exceptional choice for anyone seeking a High Density PCB that offers robust performance, adaptability, and high quality. Manufactured with premium FR4 IT180 material and designed to cater to specialized requirements like lamp socket integration, these HDI Printed Circuit Boards are poised to drive innovation in the electronics industry. Whether for consumer electronics, telecommunications, or industrial applications, our boards are engineered to deliver unparalleled performance where it matters most.

Features:

- Product Name: HDI PCB Board

- Minimum Hole Size: 0.15mm

- Hole Size: 0.1mm Laser Drill

- Aspect Ratio: 10:1

- Testing: 100%E-Testing, X-RAY

- Key Words: High Density Interconnector, HDI Printed Circuit Boards, HDI PCB, DDR4 PCB

Technical Parameters:

| Impedance Control |

Yes |

| Special Request |

Half Hole, 0.25mm BGA |

| Testing |

100%E-Testing, X-RAY |

| Minimum Hole Size |

0.15mm |

| Layer Count |

4-20 Layers |

| Board Layer |

6-32L |

| Special Requirements |

Lamp Socket |

| Raw Material |

FR4 IT180 |

| Aspect Ratio |

10:1 |

| Key Words |

High Density Interconnector, HDI PCB, High Density PCB |

Applications:

The HDI PCB Board, specifically the 4L 1+N+1 HDI Boards, boasts an impressive range of features suitable for a variety of demanding applications and scenarios. With a minimum trace of 3/3Mil and a board layer capacity ranging from 6-32L, these HDI Printed Circuit Boards offer unparalleled precision and connectivity for complex electronic assemblies. The board thickness can be customized between 0.2mm to 6.00mm (8mil-126mil), catering to a broad spectrum of product requirements.

One of the primary applications for the HDI PCB Board is in the realm of high-speed computing, where the DDR4 PCB plays a critical role. These boards are ideal for motherboards and memory expansion cards, where high-speed signal transmission is crucial. The fine trace and spacing of the HDI technology allow for the high density of memory routing that DDR4 standards demand, ensuring reliable performance and data integrity in computers, workstations, and servers.

Moreover, the versatility in thickness and layer counts makes these HDI Printed Circuit Boards perfect for use in portable and compact devices such as smartphones, tablets, and digital cameras. These products often require thin, high-density boards to accommodate their limited space while still providing the high functionality that consumers expect. The HDI PCB Board efficiently meets these demands, enabling sleeker designs without compromising on the performance or reliability of the devices.

In the field of medical electronics, where precision and reliability are paramount, the HDI PCB Board is an essential component. Medical devices such as pacemakers, imaging systems, and advanced diagnostic equipment benefit from the high-density interconnect capabilities, ensuring that these critical devices operate flawlessly and with the required miniaturization that modern medical technology seeks.

Additionally, the aerospace and defense sectors rely on the robustness and precision of HDI PCB Boards for their applications. In environments where equipment is subject to extreme conditions and reliability can mean the difference between life and death, the robust build and consistent performance of the 4L 1+N+1 HDI Boards are indispensable. Whether for communication systems, flight control systems, or surveillance equipment, these HDI boards deliver the necessary resilience and performance.

In conclusion, the HDI PCB Board, with its fine trace capabilities, variable thickness, and high layer count, is suited for a variety of high-end applications. From DDR4 PCBs in computing to critical medical device components, these boards offer the reliability and performance required for today's advanced electronic applications.

Customization:

Our High Speed PCB Board customization services cater specifically to HDI PCB designs. With an impressive aspect ratio of 10:1, we can accommodate board thicknesses ranging from 0.4mm to 3.2mm to fit your specific requirements. Our advanced capabilities allow us to fulfill special requests such as the integration of half holes and the precision placement of 0.25mm BGA for your High Density Interconnector needs. Every High Speed PCB Board we produce is meticulously crafted, featuring a 0.1mm laser drill hole size, ensuring the highest level of quality and performance for your HDI PCB applications.

Support and Services:

The HDI PCB Board is a high-density interconnect printed circuit board designed to provide advanced electrical performance and reduced space requirements. Our product technical support and services are committed to ensuring your HDI PCB Board operates at peak efficiency and reliability.

Technical Support Services:

- Comprehensive Troubleshooting - Our team will help diagnose and resolve any issues you encounter with your HDI PCB Board.

- Design Consultation - Experts are available to provide guidance on design best practices for optimal performance and manufacturability.

- Quality Assurance - We ensure that your HDI PCB Board meets all industry standards and our rigorous internal quality benchmarks.

- Firmware Updates - We provide ongoing firmware updates to improve functionality and address any potential security concerns.

Additional Services:

- Training - We offer training sessions to help your team better understand and utilize the HDI PCB Board.

- Documentation - Access to detailed product manuals, technical guides, and specifications is available to assist with product integration and usage.

- Repair Services - Should your HDI PCB Board require repairs, we offer a range of services from minor fixes to comprehensive overhauls.

- Replacement Parts - In the event that any components need to be replaced, we provide a full inventory of compatible, high-quality parts.

Our dedicated support team is here to ensure that your experience with the HDI PCB Board is seamless and productive. We strive to provide timely, efficient, and effective support for all your technical needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!