Product Description:

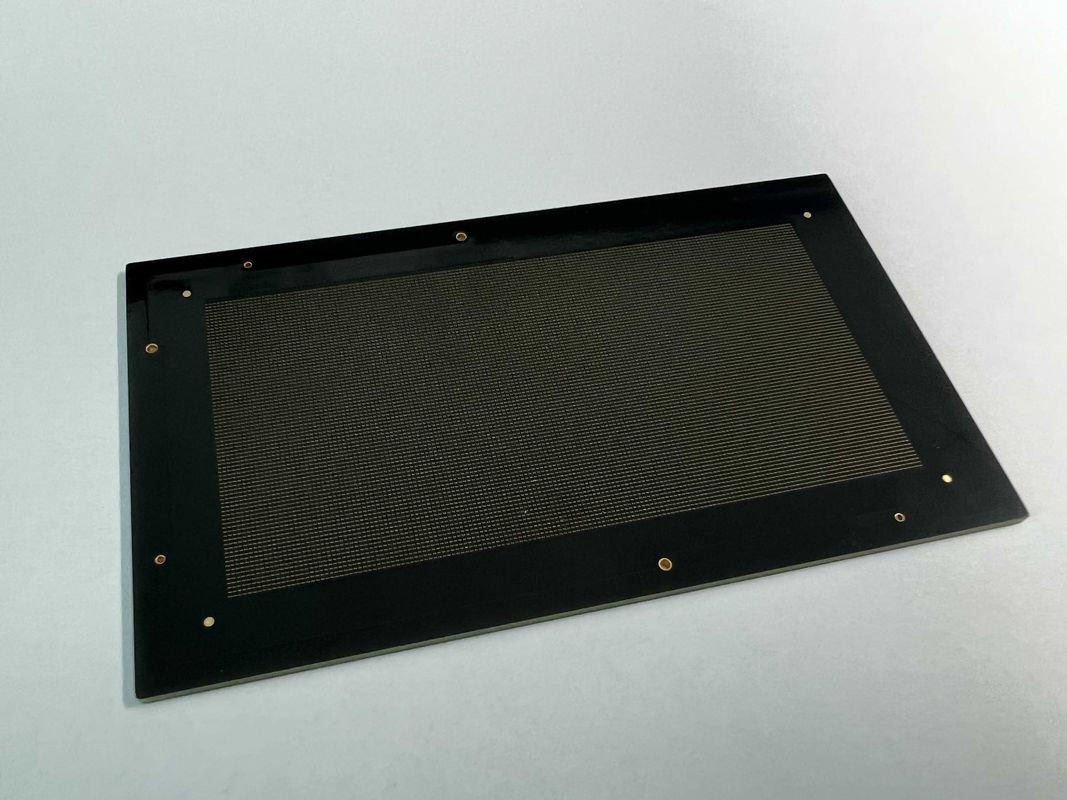

The HDI PCB Board is a cutting-edge product that offers superior performance and reliability for a wide range of applications. With VIP process capabilities, this product ensures high quality and precision in every aspect of its design and production.

As a leading provider of HDI Printed Circuit Boards, we understand the importance of delivering products that meet the highest standards of quality and performance. The HDI PCB Board is no exception, with features that set it apart from traditional PCBs.

One of the key attributes of the HDI PCB Board is its high density interconnector technology, which allows for increased routing density and improved signal integrity. This makes it an ideal choice for applications that require high-speed data transfer, such as HD SDI converters and DDR4 PCBs.

With a finished copper thickness of 1oz, the HDI PCB Board provides excellent conductivity and thermal performance, ensuring that your circuit operates efficiently and reliably. This attribute is crucial for applications that require high power handling and signal transmission capabilities.

Another standout feature of the HDI PCB Board is its minimum solder mask bridge of 0.075mm, which allows for precise soldering and assembly processes. This ensures that your components are securely connected and protected from environmental factors, enhancing the overall durability of your circuit.

When it comes to aesthetics, the HDI PCB Board offers a range of silkscreen options including white, black, yellow, and more. This allows you to customize the appearance of your PCB to suit your specific requirements or branding preferences.

In conclusion, the HDI PCB Board is a top-of-the-line product that combines advanced technology with exceptional quality and performance. Whether you are working on a high-speed data transfer project or a power-intensive application, this PCB will meet and exceed your expectations, making it a valuable addition to your electronic designs.

Features:

-

Product Name: HDI PCB Board

-

Surface Finish: HASL, ENIG, OSP, Immersion Silver, Immersion Tin, Etc.

-

Aspect Ratio: 10:1

-

Min. Solder Mask Bridge: 0.075mm

-

Finished Copper Thickness: 1oz

-

Key Words: High Density Interconnector, High Density Model Board, High Speed PCB Board, HD SDI Converter

Technical Parameters:

|

Feature

|

Immersion Silver

|

|

Mini Holes

|

0.1mm

|

|

Vias Aspect Ratio

|

16:1

|

|

Finished Copper Thickness

|

1oz

|

|

Surface Finish

|

HASL, ENIG, OSP, Immersion Silver, Immersion Tin, Etc.

|

|

Vip Process

|

Yes

|

|

Pcb Assembly Process

|

SMT THT DIP SMT PCB Assembly

|

|

Min. Solder Mask Bridge

|

0.075mm

|

|

Silkscreen

|

White, Black, Yellow, Etc.

|

|

Thickness

|

1.6mm, ±10%

|

Applications:

When it comes to high-speed and high-density electronic applications, the HDI PCB Board is the go-to solution due to its advanced features and capabilities. The Aspect Ratio of 10:1 ensures that the board is compact yet efficient, making it ideal for applications where space is limited but performance is crucial.

The use of Glass Epoxy material, specifically RO4350B from Rogers Corp., with a high Tg of 280℃ and a low Er value of less than 3.48, makes the HDI PCB Board highly reliable and capable of handling demanding operating conditions. This makes it suitable for industries such as telecommunications, aerospace, and medical devices where reliability is paramount.

With Vias Aspect Ratio of 16:1, the HDI PCB Board can accommodate a high number of interconnections in a small area, making it perfect for applications requiring complex circuitry and high signal integrity. The board is compatible with various PCB assembly processes including SMT (Surface Mount Technology), THT (Through-Hole Technology), DIP (Dual In-line Package), and SMT PCB Assembly, providing flexibility in manufacturing and assembly.

Furthermore, the availability of silkscreen options in colors such as White, Black, Yellow, etc., allows for easy identification and labeling of components on the board, enhancing the overall aesthetics and functionality of the PCB assembly.

In conclusion, the HDI PCB Board is a versatile and reliable solution for high-speed PCB applications that require compact design, high reliability, and complex circuitry. Its advanced features and capabilities make it suitable for a wide range of industries and applications, making it a preferred choice for engineers and designers looking to optimize the performance of their electronic devices.

Customization:

Product Customization Services for the HDI PCB Board:

- Min. Solder Mask Bridge: 0.075mm

- PCB Assembly Process: SMT THT DIP SMT PCB Assembly

- Aspect Ratio: 10:1

- Key Words: High Density Interconnector, High Density PCB, High Density Model Board, HDI PCB Board

- Surface Finish: HASL, ENIG, OSP, Immersion Silver, Immersion Tin, Etc.

Support and Services:

The Product Technical Support and Services for the HDI PCB Board product include:

- Assistance with product installation and setup

- Troubleshooting guidance for any technical issues

- Software updates and patches

- Product training and educational resources

- Warranty support and repairs

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!