Product Description:

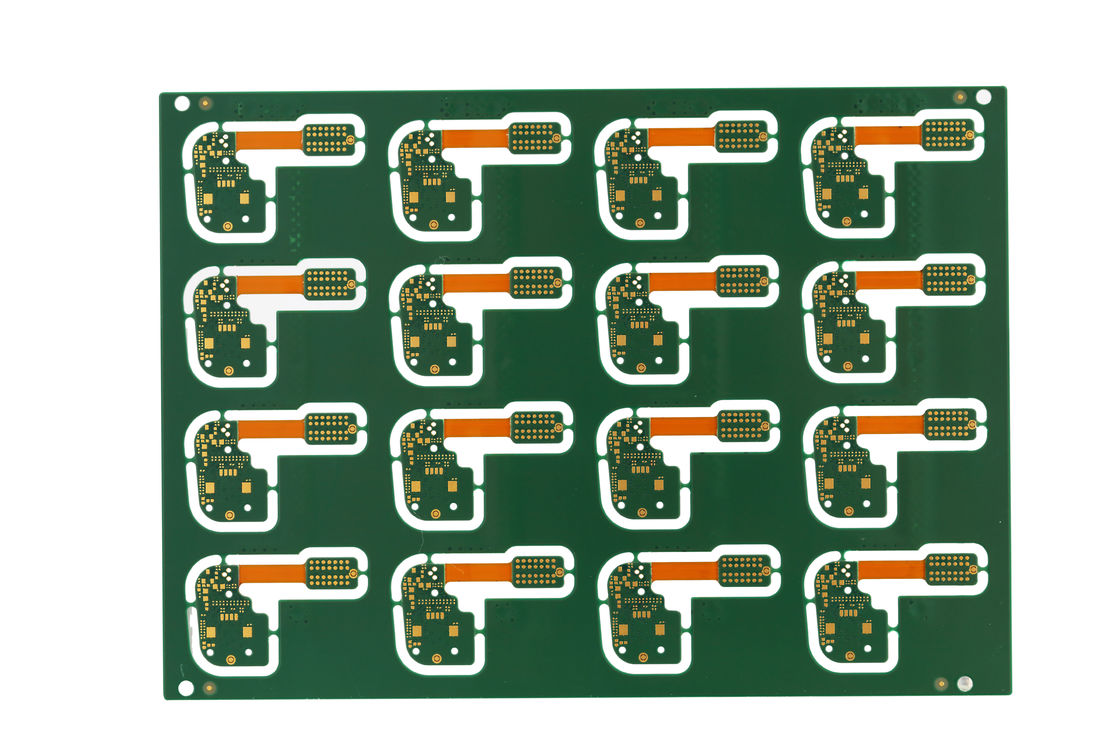

The Rigid Flex PCB is a state-of-the-art Flexible-Bendable PCB solution designed for applications that require a robust yet flexible design to fit into tight and unconventional spaces. This innovative Bendable Rigid Printed Wiring Board combines the best attributes of rigid and flexible circuitry, providing a versatile and reliable platform for a wide range of electronic applications. This product summary delves into the various aspects of the Rigid Flex PCB, including its treatment options, layer capacity, dimensions, profiling punching techniques, and precision in hole positioning.

One of the standout features of the Flex Rigid PCB is the variety of surface treatment options available. Depending on the requirements of the application, customers can choose from ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservatives), Immersion Gold, Immersion Tin, or Immersion Silver. Each treatment offers its own benefits, such as improved solderability, corrosion resistance, and wire bondability. ENIG is particularly popular for its long shelf life and excellent surface planarity, making it a great choice for fine pitch components.

When it comes to the layer capacity, this Flex Rigid PCB is unmatched with the capability to accommodate up to 52 layers (Max Layer: 52L). This remarkable layer count allows for high-density interconnects and complex circuit designs that are ideal for advanced electronic systems. Whether it is for aerospace, medical, military, or consumer electronics, the high layer count provides the design flexibility to meet the most demanding requirements.

The dimensions of the Rigid Flex PCB are another critical aspect, with a size of 41.55*131mm. This dimension facilitates the PCB's integration into a broad spectrum of devices without compromising on performance or reliability. The compact size coupled with the flexible nature of the board ensures that it can be bent and twisted to fit into irregularly shaped areas, all while maintaining a high level of durability.

Profiling punching is an essential process in PCB manufacturing, and the Rigid Flex PCB employs various methods such as Routing, V-CUT, and Beveling. These techniques are used to shape the PCB to meet specific design requirements, ensuring a perfect fit within the device. Routing is utilized to create complex contours and irregular shapes, while V-CUT is ideal for creating straight lines and easy board separation. Beveling, on the other hand, prepares the edges of the board for insertion into connectors, which is crucial for preventing damage during assembly.

Precision is paramount in PCB design, and the Rigid Flex PCB boasts a Hole Position Deviation of ±0.05mm. This level of accuracy ensures that all drilled holes are placed correctly, resulting in consistent and reliable connections between the various layers of the board. The precise hole positioning is crucial for high-speed signals and fine pitch components, as it minimizes any potential alignment issues during component placement and soldering.

In summary, the Rigid Flex PCB is a top-tier solution that embodies flexibility, durability, and precision. With its extensive treatment options, high layer capacity, compact dimensions, sophisticated profiling punching techniques, and exact hole positioning, this Flex Rigid PCB stands as an ideal choice for designers and engineers seeking a high-quality, bendable printed wiring board. It is engineered to meet the stringent requirements of today's complex electronic environments, promising performance and reliability where it matters most.

Features:

- Product Name: Rigid Flex PCB

- Dimension: 41.55*131mm

- Minimum Trace/Space: 0.1mm

- Components: SMD, BGA, DIP, Etc.

- Product Type: PCB Assembly

- Pcb Layer: 1-28 layers

- Bendable Printed Circuit Board

- Flexible Stiff Circuit Board

- Flexible-Bendable PCB

Technical Parameters:

| Parameter |

Specification |

| Flexibility |

1-8 Times |

| Minimum Trace/Space |

0.1mm |

| Sanforized |

Local High Density, Back Drill |

| Dimension |

41.55*131mm |

| Treatment |

ENIG/OSP/Immersion Gold/Tin/Silver |

| Hole Position Deviation |

±0.05mm |

| Material |

FR4, Polyimide, PET |

| Components |

SMD, BGA, DIP, Etc. |

| Product Type |

PCB Assembly |

| Profiling Punching |

Routing, V-CUT, Beveling |

Applications:

The Flex Rigid PCB, a hybrid that combines the best of both rigid and flexible circuit technologies, offers a wide array of application occasions and scenarios due to its unique attributes. With a dimension of 41.55*131mm, this Rigid Flex Printed Wiring Board is designed to seamlessly fit into compact and mechanically demanding applications where space optimization is crucial.

One of the notable attributes of this Rigid Flex PCB is its capacity for profiling punching, which includes Routing, V-CUT, and Beveling. These manufacturing processes allow for intricate designs and shapes, making the board ideal for sophisticated electronic products where precise fit and connections are paramount. Profiling punching also enables the creation of breakout tabs and complex contour cuts, ensuring that the product can be integrated into various housing and casings with ease.

With a PCB layer count ranging from 1 to 28 layers, and the capability to go up to 52L for maximum layer options, this Bendable Printed Circuit Board can serve a vast range of electronic complexities from simple single-layer devices to intricate multi-layered systems. This flexibility in design allows for the board to be employed in diverse sectors, including medical devices, aerospace, military, and consumer electronics where reliability and performance are non-negotiable.

Furthermore, the Minimum Trace/Space of 0.1mm is an attribute that underscores the board's suitability for high-density applications. As electronic components continue to shrink in size, the demand for boards that can accommodate more circuits within a limited space is increasing. This Rigid Flex Printed Wiring Board meets this demand, allowing for fine line and space requirements, which is essential for modern miniature devices.

Applications that require repeated bending or flexing are where the Bendable Printed Circuit Board truly shines. The dynamic flexing capability of this product means it can be used in foldable or wearable electronics where the board may need to conform to curves or move with the user. This high degree of flexibility without compromising circuit integrity makes it an invaluable component in developing cutting-edge, ergonomic electronic products.

In summary, the Flex Rigid PCB with its profiling punching capabilities, ideal dimensions, multilayered construction, and precise trace/space attributes is a versatile solution for a multitude of advanced electronic applications. From tightly packed handheld devices to critical aerospace components, this Rigid Flex PCB stands as a testament to the evolution of printed circuit board technology, ready to meet the challenges of modern electronic design and fabrication.

Customization:

Our Rigid Flex PCB product offers exceptional product customization services to meet your specific needs. With a Flexible Stiff Circuit Board design, our PCB combines the best of both worlds, offering the resilience of a rigid PCB with the versatility of a flexible one.

Choose from our high-precision Sanforized options including Local High Density for intricate circuit patterns and Back Drill technology for improved signal integrity. Experience flexibility like never before with our Flex Rigid PCB, which can withstand 1-8 Times of bending without compromising performance.

Our customizable Bend Radius ranges from 0.5-10mm, ensuring that our Bendable Rigid Printed Wiring Board can be tailored to fit into any assembly or configuration. The Surface Finishing of HASL LF (Hot Air Solder Leveling Lead-Free) provides a reliable and environmentally-friendly finish for your circuit boards.

We also offer a 4 Layer construction, allowing for more complex and dense circuit designs while maintaining a compact form factor. Trust in our Rigid Flex PCB to deliver the durability and flexibility your projects require.

Support and Services:

The Rigid Flex PCB product is supported by a comprehensive technical support and service package designed to provide you with the assistance you need to integrate our product into your applications seamlessly. Our support services include access to a knowledge base with extensive documentation, design guidelines, and frequently asked questions to help you troubleshoot and optimize your use of the Rigid Flex PCB.

Our technical support team is composed of industry experts who are committed to providing you with timely and effective solutions. They have deep knowledge of the product and its applications, ensuring that you receive the most relevant and practical advice. Please note that for specific queries or issues requiring personalized support, we encourage you to reach out through our designated channels which can be found on our contact page.

In addition to personalized support, we offer a range of services to enhance your experience with the Rigid Flex PCB. This includes design review services, to ensure that your PCB design meets all necessary specifications and is optimized for manufacturing, as well as after-sales support to assist with any post-purchase inquiries or concerns.

We are dedicated to your success and strive to provide services that not only address your immediate needs but also help in the long-term reliability and performance of your Rigid Flex PCB applications. Our commitment to customer satisfaction is at the core of our support and service philosophy.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!