Product Description:

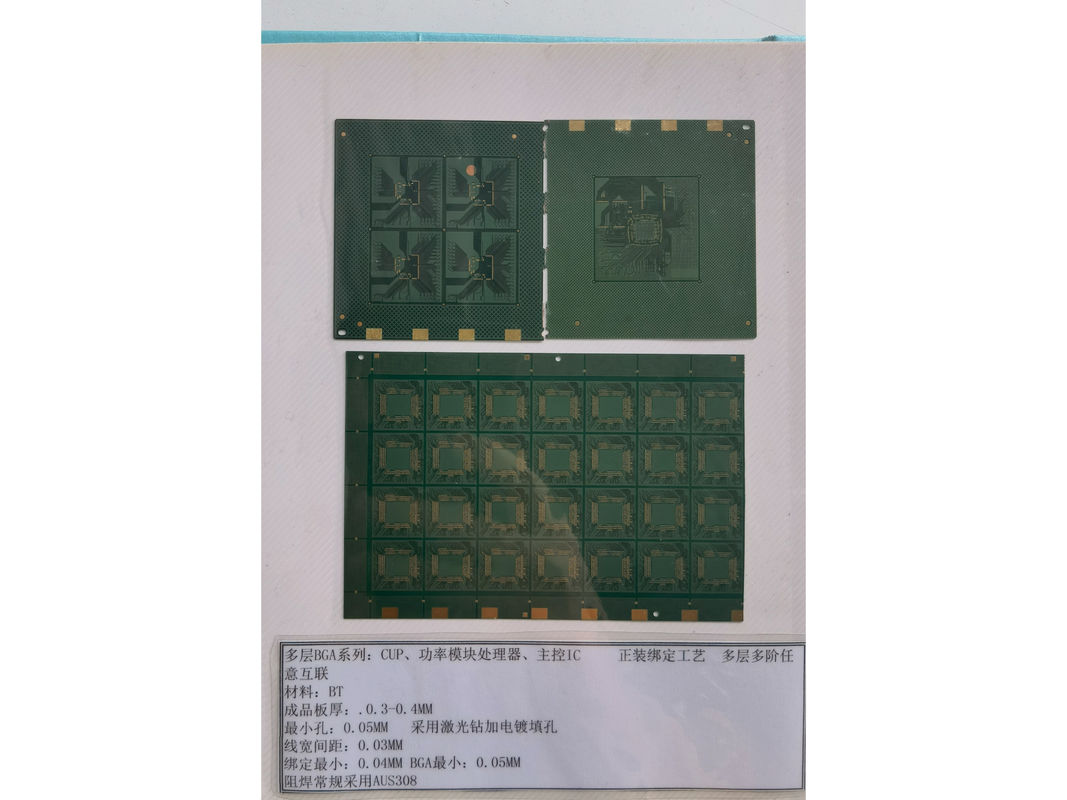

The Integrated Circuit Substrate PCBs are at the heart of the electronics industry, serving as the foundational bedrock for chip board assemblies. These printed circuit boards for ICs are meticulously engineered to meet the rigorous demands of modern electronics, providing unparalleled reliability and performance. The substrate PCBs are not just components; they are the essential platforms that bring to life the myriad of functionalities in various electronic devices.

One of the fundamental attributes of our IC Substrate PCBs is the use of high-quality ceramic materials. Ceramic, known for its excellent thermal properties and electrical insulation, makes these substrates ideal for high-performance applications. The ceramic material ensures that the PCB can withstand high temperatures without compromising its structural integrity or electrical properties. This durability is critical for applications that require maximum reliability under thermal stress.

Another key specification of these substrates is their copper weight. With a standard 1oz copper weight, these PCBs strike the perfect balance between conductivity and thermal management. The copper traces are thick enough to carry significant current without overheating, yet not so thick as to become rigid or difficult to work with. This copper weight is a standard in the industry, providing the reliable electrical performance required for integrated circuit functionality.

The solder mask color of these PCBs is the traditional green. This color is not only industry standard but also provides a high contrast background that aids in visual inspections and highlights the presence of any flaws or soldering errors. The green solder mask is applied over the copper traces to insulate and protect them from accidental contact or corrosion, thereby improving the longevity and reliability of the assembly.

When it comes to operating conditions, these PCBs are built to withstand extreme environments. The maximum operating temperature of 150°C ensures that the IC Substrate PCBs can function effectively in a wide range of temperatures without performance degradation. This high threshold for heat resistance is particularly important for applications where the circuitry may be subjected to high power densities or enclosed spaces where heat dissipation is a challenge.

The thickness of these substrates is another critical dimension. At a mere 0.2mm, these PCBs are incredibly thin, allowing for compact and lightweight chip board assemblies. The slim profile, however, does not compromise the substrate's strength or functionality. This thickness enables high-density interconnects and the inclusion of multiple layers within the PCB if necessary, which is pivotal for the miniaturization of electronic devices and the trend towards more complex circuit designs.

In conclusion, the Integrated Circuit Substrate PCBs we offer are tailored to meet the specific needs of the electronics industry. With a focus on material quality, thermal performance, and precise manufacturing standards, these substrates are ideal for a range of applications. Whether for consumer electronics, automotive systems, or industrial machinery, our PCBs ensure that your integrated circuits are supported by a foundation that is both robust and refined. The combination of a 1oz copper weight, a green solder mask, and high-temperature resilience makes these PCBs a dependable choice for designers and engineers looking to push the envelope of electronic innovation.

Features:

- Product Name: IC Substrate PCBs

- Minimum Trace Width: 0.1mm

- Rohs Compliant: Yes

- Layers: 2 - Microelectronics Circuit Layers

- Material: Ceramic - Ideal for Chip Board Assemblies

- Maximum Operating Temperature: 150°C

Technical Parameters:

| Parameter |

Specification |

| Copper Weight |

1oz |

| Layers |

2 |

| Size |

10mm X 10mm |

| Thickness |

0.2mm |

| Substrate Type |

Rigid |

| Minimum Trace Width |

0.1mm |

| Maximum Operating Temperature |

150°C |

| Minimum Trace Spacing |

0.1mm |

| Surface Finish |

ENIG |

| Lead Time |

2 Weeks |

Applications:

The IC Substrate PCBs, composed of high-quality ceramic materials, are a pivotal component in the modern electronics industry. These substrates serve as the foundational platform for chip board assemblies, where precision and reliability are of paramount importance. Being RoHS compliant, they meet the necessary environmental standards by avoiding the use of hazardous substances in their construction, thus ensuring safety and sustainability in their applications.

With a maximum operating temperature of 150°C, these IC Substrate PCBs can withstand high thermal conditions, making them suitable for use in environments that experience elevated temperatures. This characteristic is particularly beneficial in power-intensive embedded system circuit boards where thermal management is crucial for maintaining performance and extending the lifespan of electronic components.

The rigid substrate type ensures a stable and robust platform for electronic components, creating a dependable structure for computer chip substrate panels. This rigidity is essential in high-vibration environments or in applications where mechanical stress might otherwise compromise the integrity of the circuitry.

Furthermore, the precision in the manufacturing of these IC Substrate PCBs is highlighted by the minimum hole size of 0.2mm, allowing for the accommodation of fine-pitch components. This level of detail is necessary for the miniaturization trends in electronics, especially in embedded system circuit boards that require dense component placements without sacrificing performance or reliability.

Applications of these IC Substrate PCBs are vast and varied. They are indispensable in the realm of consumer electronics, where they form the backbone of smartphones, tablets, and laptops. In the automotive sector, they are used in the creation of advanced driver-assistance systems (ADAS) and other critical vehicle electronics that demand high reliability under harsh conditions. Additionally, these substrates are integral to the aerospace industry, where they contribute to the functionality of avionics and navigational systems that require faultless operation.

In the realm of industrial applications, these IC Substrate PCBs are also widely used. From manufacturing robotic controls to complex networking equipment, they provide the necessary support for embedded system circuit boards that control various high-precision tasks. Moreover, medical devices that rely on computer chip substrate panels for diagnostics, imaging, and patient monitoring also benefit from the high standards of these IC Substrate PCBs. The consistent quality ensures that these life-saving devices perform accurately and reliably.

To summarize, the IC Substrate PCBs are an essential component in a myriad of technological applications. Their compliance with RoHS standards, high maximum operating temperature, rigid substrate type, and precise minimum hole size make them suitable for a wide range of scenarios where embedded system circuit boards, computer chip substrate panels, and chip board assemblies are vital.

Customization:

Our Printed Circuit Boards for ICs are designed to meet the specific demands of the semiconductor industry. With a Minimum Trace Width of 0.1mm , these boards provide exceptional precision for your high-density designs. Constructed from high-quality Ceramic material, our IC Substrate PCBs ensure long-lasting durability and performance.

All of our Processor Platform PCBs are Rohs Compliant to ensure environmental safety and adherence to industry standards. With 2 layers of substrate, our boards offer a reliable foundation for your processing needs.

Designed with a focus on stability, the Rigid Substrate Type of our Semiconductor Packaging Boards guarantees a solid platform for your IC components. Customize your PCBs with us and elevate the performance of your semiconductor devices.

Support and Services:

Our IC Substrate PCBs are designed with precision and manufactured to the highest quality standards. Our technical support and services are dedicated to providing you with the assistance you need to integrate our products seamlessly into your projects. We offer a comprehensive suite of services to ensure your satisfaction and the optimal performance of your IC Substrate PCBs.

Technical Support Services include:

- Product Selection Assistance - Helping you choose the right IC Substrate PCB for your specific application needs.

- Design Guidelines - Providing you with detailed design guidelines to optimize the functionality and reliability of your PCBs.

- Layout Review - Offering expert review services to ensure your PCB layout meets industry standards and our manufacturing capabilities.

- Troubleshooting - Assisting you in diagnosing and resolving any issues you may encounter during the installation or use of our PCBs.

Additional Services:

- Prototype Services - Enabling you to test and validate your designs before moving to full-scale production.

- Quality Assurance - Implementing rigorous testing procedures to guarantee the quality and performance of our PCBs.

- After-Sales Support - Providing ongoing support to address any post-purchase questions or concerns.

- Training Programs - Offering training sessions to familiarize your team with our products and help you get the most out of your IC Substrate PCBs.

We are committed to your success and strive to provide you with the best possible support and services for our IC Substrate PCBs. For any technical concerns or service-related inquiries, please refer to our support documentation or reach out to our customer service team for prompt assistance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!