Product Description:

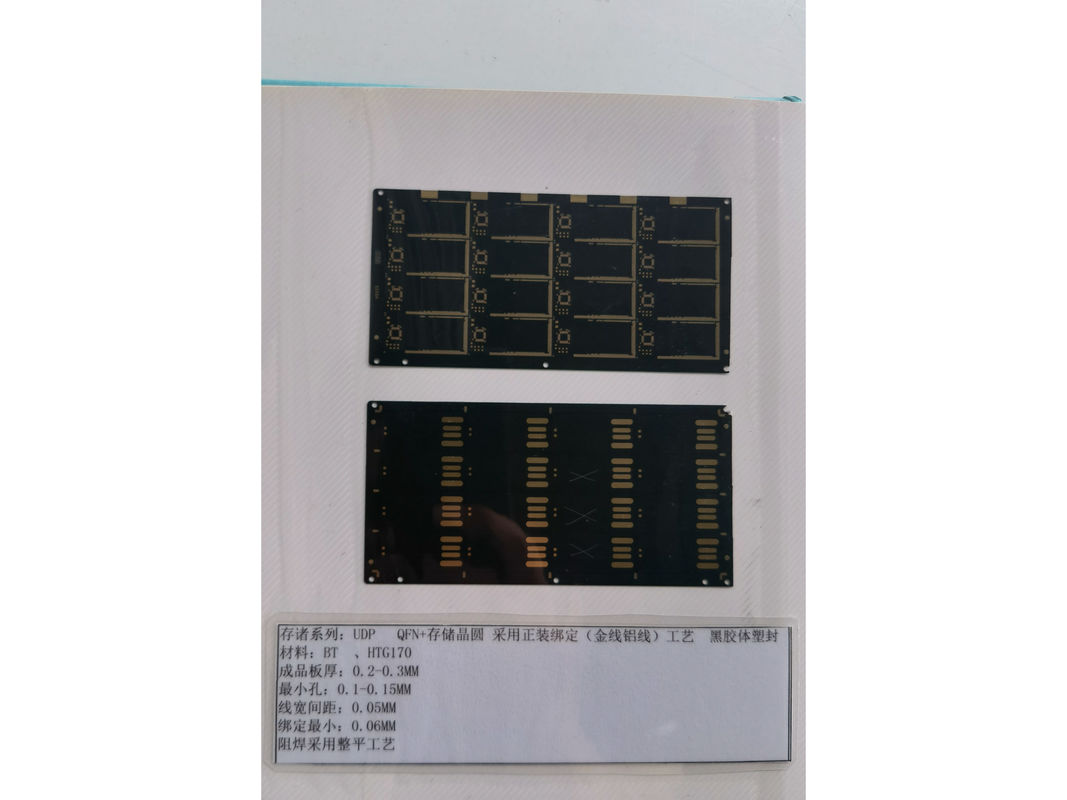

The IC Substrate PCBs represent a pinnacle of microelectronic engineering, embodying precision and reliability in a compact package. These Printed Circuit Boards for ICs are designed to support the intricate connections and rapid signal transmissions required by modern integrated circuits and embedded systems. The utilization of these substrates is integral to the performance and miniaturization of electronic devices, ranging from consumer gadgets to sophisticated industrial machinery.

With a Minimum Trace Width of just 0.1mm, these PCBs are manufactured to accommodate the high-density routing needed by today's complex circuit designs. This fine trace width allows for a greater number of electrical pathways in a given area, which is essential for the multi-functionality of contemporary Embedded System Circuit Boards. Such precision ensures that signals can travel with minimal interference, boosting the overall efficiency and speed of the electronic device.

Consisting of 2 layers, these IC Substrate PCBs offer a balanced approach to functionality and form factor. The bi-layer configuration provides a foundation for the essential electronic components while maintaining a slim profile. This is particularly advantageous for applications where space is at a premium, such as in mobile devices, wearable technology, and other compact embedded systems.

With a rapid Lead Time of just 2 Weeks, these IC Substrate PCBs are not only a testament to the advancement in manufacturing speed but also to the commitment to meet the fast-paced demands of the electronics industry. This quick turnaround time ensures that project timelines are maintained, keeping development cycles short and efficient, which is particularly beneficial for time-sensitive projects and rapid prototyping needs.

The Minimum Hole Size of 0.2mm in these PCBs is indicative of the meticulous attention to detail that goes into their manufacturing. This allows for the accommodation of fine-pitch components, which are increasingly prevalent in sophisticated electronic assemblies. It also enables the use of smaller vias, which in turn contributes to the overall compactness of the circuit board design. This feature is critical for high-density Embedded System Circuit Boards where every millimeter counts.

The Surface Finish of these IC Substrate PCBs is Electroless Nickel Immersion Gold (ENIG). This finish not only provides a flat and solderable surface, which is ideal for today's surface-mount technology, but it also offers excellent corrosion resistance, ensuring a long-lasting and reliable electrical connection. The ENIG finish is also known for its superior thermal endurance, which is crucial for maintaining the integrity of the Printed Circuit Boards for ICs under varying operational temperatures.

In summary, the IC Substrate PCBs product is an exemplary solution for modern electronics demanding high performance and miniaturization. With features such as a 0.1mm Minimum Trace Width, 2-layer configuration, expedited 2-week Lead Time, 0.2mm Minimum Hole Size, and a durable ENIG Surface Finish, these PCBs are uniquely tailored to meet the needs of advanced integrated circuits and embedded systems. Whether for consumer electronics, medical devices, or industrial applications, these Printed Circuit Boards for ICs are set to serve as the backbone of contemporary and future electronic innovations.

Features:

- Product Name: IC Substrate PCBs

- Substrate Type: Rigid

- Copper Weight: 1oz

- Layers: 2

- Size: 10mm X 10mm

- Solder Mask Color: Green

- Also known as Microchip Substrate Boards

- Integral part of Embedded System Circuit Boards

- Essential for Computer Chip Substrate Panels manufacturing

Technical Parameters:

| Parameter |

Specification |

| Maximum Operating Temperature |

150°C |

| Minimum Trace Width |

0.1mm |

| Material |

Ceramic |

| Minimum Trace Spacing |

0.1mm |

| Copper Weight |

1oz |

| Rohs Compliant |

Yes |

| Thickness |

0.2mm |

| Lead Time |

2 Weeks |

| Solder Mask Color |

Green |

| Substrate Type |

Rigid |

Applications:

The IC Substrate PCBs, with their meticulous design featuring a minimum hole size of 0.2mm, are perfectly suited for various high-density applications. These substrate circuit boards form the backbone of many chip board assemblies, ensuring that even the tiniest components can be accommodated with precision. The compact size of 10mm x 10mm makes these PCBs ideal for use in devices where space is at a premium, yet high performance is non-negotiable.

Bearing a sophisticated surface finish of Electroless Nickel Immersion Gold (ENIG), these IC Substrate PCBs offer exceptional solderability and are resistant to oxidation. This quality surface finish not only enhances the durability of semiconductor packaging boards but also ensures reliable signal transmission, which is crucial in high-speed applications. The ENIG finish, paired with the board's compliance with RoHS (Restriction of Hazardous Substances), signifies a commitment to environmental responsibility while maintaining the highest standards of product quality and safety.

Processor platform PCBs, such as the IC Substrate PCBs, are engineered to withstand extreme conditions, with a maximum operating temperature of 150°C. This attribute makes them suitable for deployment in demanding environments like industrial automation, automotive electronics, and aerospace applications where they must operate reliably over a wide range of temperatures.

The IC Substrate PCBs are also extensively used in the realm of consumer electronics, medical devices, and communication systems. Their robust design enables them to support the intricate workings of smartphones, tablets, and wearable technology, where they help manage the operations of microprocessors and other critical semiconductor components. In the medical field, these high-precision boards are integral to diagnostic equipment and portable medical instruments, where consistent performance can be a matter of life and death.

In summary, the IC Substrate PCBs are a versatile and essential component in modern electronics. Their small size, high-temperature tolerance, and superior surface finish make them suitable for a wide array of applications, including but not limited to chip board assemblies, processor platform PCBs, and semiconductor packaging boards. Whether in consumer gadgets or industrial machinery, these PCBs guarantee reliability and performance in the most demanding situations.

Customization:

Our IC Substrate PCBs offer premium product customization services that cater to high-precision chip board assemblies. With a focus on semiconductor packaging boards, we ensure that each substrate meets the highest industry standards. Our customization options include:

Surface Finish: We utilize the Electroless Nickel Immersion Gold (ENIG) surface finish for superior solderability and longevity, essential for reliable microelectronics circuit layers.

Layers: Our substrates are available in a 2-layer configuration, providing a stable foundation for complex chip board assemblies.

Rohs Compliant: We are committed to environmental responsibility, and our IC Substrate PCBs are 100% RoHS compliant, ensuring the exclusion of hazardous substances in semiconductor packaging boards.

Minimum Trace Width and Spacing: We offer advanced precision with a minimum trace width and spacing of 0.1mm, accommodating the intricate designs necessary for high-density microelectronics circuit layers.

Support and Services:

Our IC Substrate PCBs come with comprehensive technical support and services to ensure the highest level of performance and reliability. Our support includes an extensive range of services such as product troubleshooting, performance optimization, and technical guidance.

We offer detailed technical documentation for our IC Substrate PCBs, which includes product specifications, installation guides, and maintenance procedures to help you get the most out of our products. Our technical support team is ready to assist you with any product-related inquiries or issues you may encounter.

In addition to reactive support, we provide proactive services such as periodic health checks and system updates to ensure your IC Substrate PCBs are operating at their best. We also offer training services to help your team understand the technology and get the most out of the product.

For complex projects, we have a team of engineers who specialize in the design and integration of IC Substrate PCBs and can work with you to create customized solutions tailored to your specific needs.

Please refer to our product documentation and resources for immediate assistance, and do not hesitate to reach out to our technical support team for any further help or to schedule a service.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!