Product Description:

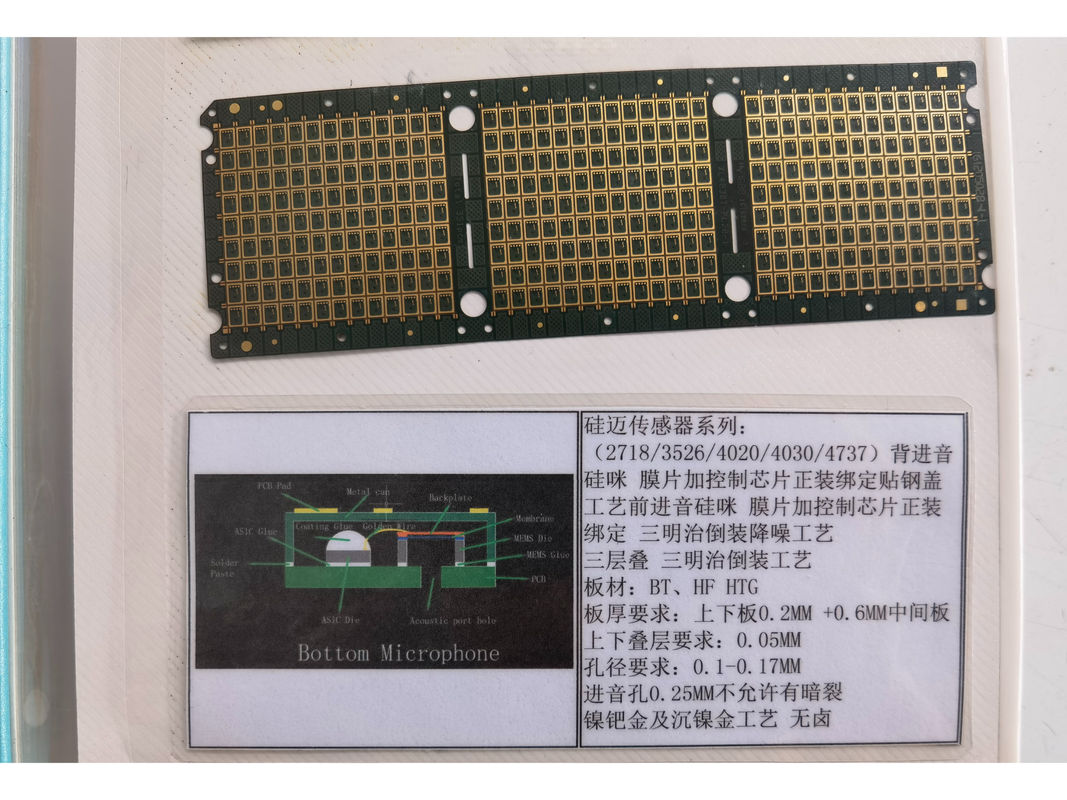

The Integrated Circuit Substrate PCBs are at the forefront of technological innovation, providing robust platforms for mounting and interconnecting various electronic components. As the backbone of modern electronics, these PCBs are central to the operation of countless devices, serving as the critical link between the complex world of integrated circuits and the functionality they deliver. Our IC Substrate PCBs are designed with precision engineering, catering to the high-performance demands of today's sophisticated electronic applications.

Constructed from high-quality ceramic materials, our Computer Chip Substrate Panels offer exceptional durability and thermal stability. Ceramic, known for its excellent insulating properties, ensures that the IC Substrate PCB operates effectively even under significant thermal stress. This makes it a preferred choice for applications requiring both high thermal conductivity and electrical isolation. The use of ceramic material also contributes to the overall longevity of the PCB, as it resists degradation over time and maintains its structural integrity even in challenging environments.

Our IC Substrate PCBs boast a standard copper weight of 1oz, which is crucial for ensuring adequate current carrying capacity and reducing resistive losses. The copper traces are meticulously laid out to provide a reliable pathway for electrical signals, and the 1oz copper weight strikes an optimal balance between electrical performance and physical robustness. This copper layer is essential for the distribution of power and signals throughout the Electronic Circuit Interconnects, contributing to the overall efficiency and effectiveness of the final product.

The precision of our manufacturing process is further exemplified by the minimum hole size of 0.2mm. These minuscule apertures are drilled with extreme accuracy to accommodate the fine leads of modern electronic components, ensuring snug fits and secure connections. The small hole size enhances the board's density, enabling the creation of more complex circuits within a compact space. This capability is a testament to the advanced technology and meticulous attention to detail that goes into the production of every IC Substrate PCB we offer.

Given the compact size of 10mm X 10mm, our IC Substrate PCBs are tailored for applications where space is at a premium. This diminutive footprint allows for their deployment in the most space-constrained environments, without compromising on performance or reliability. The small size of the PCBs makes them particularly suited for use in portable devices, wearables, and other applications where efficiency and miniaturization are key considerations.

Moreover, the maximum operating temperature of 150°C ensures that our products can withstand the rigors of high-temperature environments. This characteristic is critical for maintaining the performance and reliability of the Integrated Circuit Substrate PCBs in conditions that would compromise lesser materials. The ability to operate effectively up to 150°C opens up a range of possibilities for deployment in industrial, automotive, and other high-temperature applications, where reliability is paramount.

In summary, our Integrated Circuit Substrate PCBs represent the pinnacle of current PCB technology, offering unmatched reliability, efficiency, and performance. The combination of a robust ceramic base, optimal copper weight, precise hole sizing, compact dimensions, and high-temperature resilience makes our Computer Chip Substrate Panels an indispensable component for any demanding electronic application. Whether you are designing the next generation of consumer electronics or engineering solutions for industrial systems, our Electronic Circuit Interconnects provide the solid foundation necessary for success in an increasingly electronic world.

Features:

- Product Name: IC Substrate PCBs

- Substrate Type: Rigid

- Minimum Hole Size: 0.2mm

- Layers: 2

- Size: 10mm X 10mm

- Solder Mask Color: Green

- Keywords: Embedded System Circuit Boards

- Keywords: Semiconductor Packaging Boards

- Keywords: Printed Circuit Boards for ICs

Technical Parameters:

| Parameter |

Specification |

| Solder Mask Color |

Green |

| Rohs Compliant |

Yes |

| Material |

Ceramic |

| Surface Finish |

ENIG |

| Lead Time |

2 Weeks |

| Substrate Type |

Rigid |

| Size |

10mm X 10mm |

| Minimum Trace Spacing |

0.1mm |

| Minimum Trace Width |

0.1mm |

| Layers |

2 |

Applications:

IC Substrate PCBs (Printed Circuit Boards) are a critical component in the realm of microelectronics, acting as a stable and reliable platform for the mounting and interconnection of various electronic components. The IC substrate serves as the backbone for microelectronics circuit layers, providing the essential physical structure on which electronic circuits are built. With the advent of sophisticated electronics, the demand for high-quality substrates with precise specifications has become paramount. Our IC Substrate PCBs, made from high-grade ceramic material, are designed to meet these exacting requirements.

The ceramic material used in our IC Substrates provides exceptional thermal stability and electrical insulation, crucial for maintaining the integrity of microelectronics circuit layers. This makes them ideal for high-density and high-frequency applications where thermal management and electrical performance are critical. The robust nature of these ceramic substrates also ensures high reliability and longevity of the electronic circuit interconnects, significantly reducing the risk of circuit failures.

Our IC Substrate PCBs come with a sophisticated ENIG (Electroless Nickel Immersion Gold) surface finish, ensuring excellent solderability and corrosion resistance. This surface finish is essential for maintaining strong and reliable connections between the processor platform PCBs and the components they support. Moreover, the ENIG finish provides a flat surface, which is particularly beneficial for the mounting of BGA (Ball Grid Array) and other fine-pitch devices where precision is vital.

The compact size of 10mm X 10mm makes these IC Substrate PCBs suitable for a wide range of applications where space is at a premium. These substrates can be seamlessly integrated into various electronic devices, from smartphones and tablets to medical devices and aerospace components. The minimal footprint also allows for greater flexibility in design, enabling more complex circuitry to be fitted into smaller spaces.

Precision is key in the manufacture of our IC Substrate PCBs. The minimum hole size of 0.2mm allows for the incorporation of fine-pitch components, essential for today's miniaturized electronic devices. Meanwhile, the minimum trace spacing of 0.1mm enables the creation of high-density electronic circuit interconnects without the risk of short-circuiting. This precise spacing is crucial for maintaining signal integrity, especially in processor platform PCBs where data transfer rates are high.

Our IC Substrate PCBs are a cornerstone in the construction of robust, high-performance electronic assemblies. They are especially suited for advanced technological applications such as high-speed computing, telecommunications, and precision instrumentation. By providing a reliable foundation for electronic circuit interconnects, these substrates play a pivotal role in the advancement of today's cutting-edge electronic devices and systems.

Customization:

Our IC Substrate PCBs are designed to meet the precise needs of your electronic circuit interconnects. With a slim profile of just 0.2mm in thickness, these printed circuit boards for ICs incorporate 2 microelectronics circuit layers, ensuring compact yet robust performance. Our products are RoHS compliant, adhering to the highest environmental standards for your peace of mind. Expect swift delivery, with a lead time of only 2 weeks, and depend on the quality that comes with a copper weight of 1oz for reliable conductivity. Customize your IC Substrate PCB with us for superior electronic performance.

Support and Services:

Our IC Substrate PCBs come with comprehensive technical support and services designed to ensure the highest level of performance and reliability. Our team of experienced engineers is available to assist with product specification, design optimization, and integration into your specific applications. We provide detailed technical documentation, including product datasheets, material properties, and design guidelines, to support your development process.

In addition to technical consultation, we offer a range of services to facilitate the smooth implementation of our IC Substrate PCBs into your projects. These services include design review, thermal analysis, signal integrity analysis, and power integrity analysis to ensure your product meets all the necessary requirements for optimal functionality. We also provide prototype testing and validation services to identify and address any potential issues before full-scale production.

Our commitment to quality means that we stand behind our IC Substrate PCBs with robust after-sales support. Should you encounter any challenges or require assistance during the use of our products, our technical support team is ready to provide prompt and effective solutions. We are dedicated to ensuring the success of your projects and the long-term performance of our products.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!