Product Description:

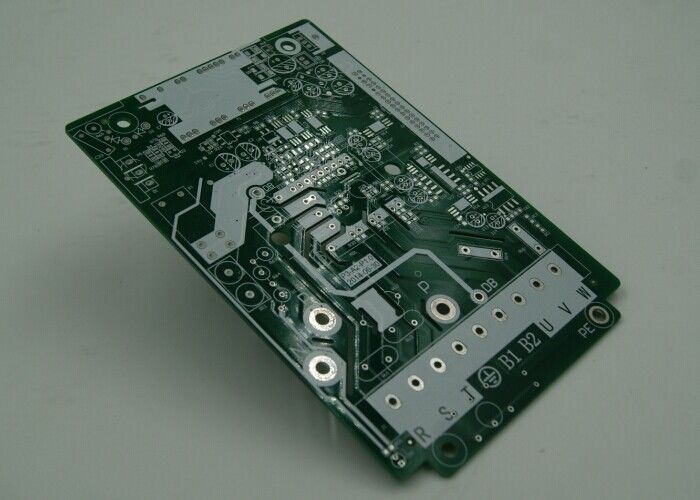

The Heavy Copper PCB is a robust, high-quality printed circuit board designed to cater to applications that demand high power distribution, enhanced current carrying capacity, and enduring thermal management. Built with precision engineering, this PCB is not just another addition to your electronic components but a significant upgrade that empowers your devices to perform with superior efficiency and reliability. With a minimal line space of 3mil (0.075mm), this PCB ensures intricate designs without compromising on the quality and connectivity of the circuitry.

Crafted with a substantial copper thickness ranging from 6 to 10 OZ, the Heavy Copper PCB is a testament to durability and functionality. The enhanced copper thickness is a vital feature that allows the PCB to conduct higher currents, tolerate more extreme thermal strains, and provide a robust mechanical anchor for the component leads. This makes it an ideal choice for high-power industrial applications, automotive power electronics, and other fields where high power density is a critical requirement.

Ensuring the highest standards of quality, every Heavy Copper PCB undergoes 100% Testing. This rigorous testing protocol ensures that each PCB delivered meets the stringent performance criteria and is free from defects. The comprehensive testing routine checks for continuity, insulation, thermal resistance, and other critical parameters that define the performance and longevity of the PCB in real-world applications. This dedication to quality assurance translates to unparalleled reliability for the end-users.

The manufacturing process of the Heavy Copper PCB includes an Immersion Gold or Silver finish, which offers multiple benefits. The surface finish not only provides excellent surface planarity for intricate component placement but also ensures a reliable soldering surface. The use of precious metals like gold and silver also significantly enhances the PCB's resistance to oxidation and corrosion, thereby extending its operational life and maintaining a consistent performance level throughout.

Adhering to the IPC-A-610 Class II-III standard, the Heavy Copper PCB is aligned with the industry's accepted criteria for electronic assemblies. This standard encompasses the target conditions for electronic products that are required to perform consistently in their service environment. Class II pertains to dedicated service electronic products, which ensures that the PCB is reliable enough to handle periodic service interruptions. On the other hand, Class III is for high-reliability electronic products that demand uninterrupted service and extended life. The adherence to these standards reflects the PCB's capability to serve in both standard and critical applications.

When describing the Heavy Copper PCB, it's important to note the terms Copper-Clad PCB and Copper-Rich PCB. These terms are indicative of the board's construction and composition, which emphasize the use of a generous amount of copper. Copper-Clad PCB refers to the type of PCB where one or both sides are covered with a significant copper layer, enhancing its electrical and thermal performance. Similarly, Copper-Rich PCB is a term that highlights the board's enriched copper content, which is pivotal for applications requiring high power density and thermal dissipation.

In summary, the Heavy Copper PCB stands out as a powerful, reliable, and versatile solution for modern electronic needs. With its impressive copper thickness, meticulous design and testing, and adherence to high standards, it is poised to serve a wide range of applications that demand the best in circuit board technology. Whether it's for industrial-grade equipment, critical medical devices, or cutting-edge automotive systems, this PCB is engineered to deliver performance and reliability in the most demanding environments.

Features:

- Product Name: Heavy Copper PCB

- Solder Mask Thickness: 20-50UM

- Hs Code: 8534009000

- Pcb Test: 100% Testing

- Production Name: Print Circuit Board

- Board Size: 6*9cm

- Also known as Copper-Clad PCB

- High Copper Content PCB for enhanced conductivity

- Durable Copper-Infused PCB for long-lasting use

Technical Parameters:

| Parameter |

Specification |

| Production Name |

Print Circuit Board |

| Pcb Test |

100% Testing |

| Solder mask thickness |

20-50UM |

| Standard |

IPC-A-610 Class II-III |

| Package |

Carton + Binding Tape |

| Board Size |

6*9cm |

| Pcb Standard |

IPC-II Standard |

| Minimum Line Space |

3mil (0.075mm) |

| Copper thickness |

6-10 OZ |

| Solder Mask |

Blue |

Applications:

The Heavy Copper PCB, characterized by its robust solder mask thickness ranging from 20-50UM and a reliable 2-layer construction, is an essential component in various high-demand applications. Its sturdy nature, ensured by the copper-clad laminate, makes it an ideal choice for scenarios where superior current carrying capacity is required. The additional protection provided by the solder mask helps in maintaining the integrity of the PCB in challenging environments.

Equipped with a layer count of 2, the Heavy Copper PCB can be applied in power electronics where multiple power levels are processed within the same unit. The thick copper layers facilitate the handling of high currents, heat dissipation, and provide a strong mechanical structure. This PCB is widely used in power supply systems, automotive industries, and in the manufacturing of solar panel arrays, where stable and efficient energy management is pivotal.

The robust nature of the Copper-Laden PCB makes it a perfect fit for military and aerospace applications. Devices that are exposed to extreme conditions and are required to perform without failure, such as in satellite systems and avionics, benefit from the reliability of these heavy copper circuits. The enhanced thickness of the copper ensures that the PCB can withstand high temperatures and mechanical stress, which are common in these fields.

Moreover, when it comes to the packaging, the Heavy Copper PCB is securely housed in cartons and bound with tape to ensure safe transportation and handling. The attention to packaging detail reflects the quality and care taken to maintain the product integrity until it reaches the consumer. For quality assurance, the PCB undergoes 100% testing to guarantee that each board meets the stringent performance criteria expected in high-end and critical applications.

Industrial controls also leverage the durability of the Heavy Copper PCB. In environments where equipment is exposed to harsh chemicals or mechanical abrasion, the copper-laden layers offer a resilient solution that can prolong the life of the electronic components. The robust construction minimizes the need for frequent maintenance or replacement, leading to more reliable and cost-effective operations.

In summary, the Heavy Copper PCB product is well-suited for a range of applications including, but not limited to, power electronics, automotive, aerospace, military, and industrial controls. Its significant solder mask thickness, 2-layer configuration, secure packaging, and thorough testing protocols ensure that it stands up to the rigorous demands of various scenarios where reliability and performance are non-negotiable.

Customization:

Our Copper-Rich PCB customization services adhere to the rigorous standards of IPC-A-610 Class II-III, ensuring the highest quality and reliability for your heavy-duty applications. We specialize in Weighty Copper PCB production with an advanced Immersion Gold/Silver process that enhances the conductivity and longevity of your boards.

Under the Hs Code 8534009000, we provide precision engineering to achieve a Minimum Line Width of 3mil (0.075mm), catering to the most demanding electrical requirements. Our Copper-Clad PCBs are available in a convenient board size of 6*9cm, tailor-made to fit compact and complex designs.

Support and Services:

Our Heavy Copper PCB product is backed by comprehensive technical support and services designed to ensure your complete satisfaction and the optimal functioning of your PCBs. Our technical support team is knowledgeable about all aspects of Heavy Copper PCB design, manufacturing, and application. They are ready to assist you with any questions or concerns you may have regarding your PCBs.

Services include detailed product documentation, guidelines for PCB layout, material selection advice, and thermal management tips. We offer troubleshooting assistance to address issues such as electrical performance, mechanical integrity, and heat dissipation. Our goal is to provide you with the information and support you need to ensure your Heavy Copper PCBs perform reliably in your specific applications.

Additionally, we provide guidance on best practices for installation and maintenance, helping you extend the lifespan and reliability of your PCBs. If you encounter any challenges during installation or operation, our team is equipped to provide you with prompt and effective solutions.

For any custom requirements or technical inquiries, we have a team of experts who specialize in custom solutions and are eager to work with you to meet your unique needs. Our commitment to excellence ensures that you receive the highest level of service and support for your Heavy Copper PCB products.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!