Product Description:

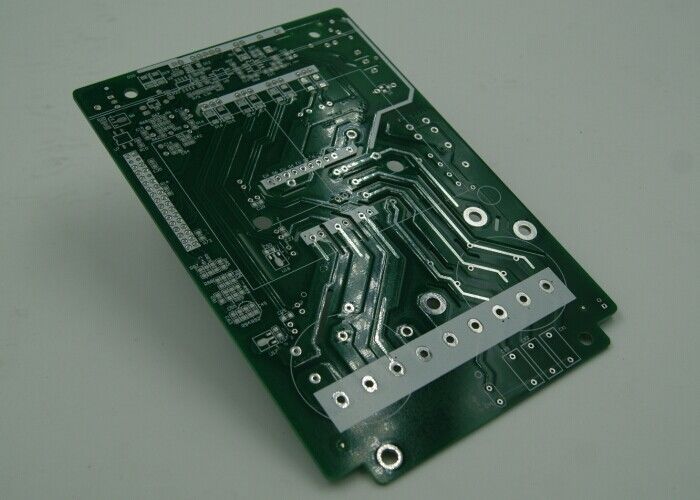

The Heavy Copper PCB, with its robust and resilient nature, is an advanced solution in the realm of Printed Circuit Boards. This Copper-Laden PCB is specifically designed to cater to applications requiring high power distribution, high endurance, and excellent thermal management. Manufactured under the production name "Print Circuit Board," this product is a prime example of engineering excellence and quality assurance. With a focus on reliability and durability, the Heavy Copper PCB stands out as a superior substrate for a wide range of electronic applications.

At the heart of its design, the Heavy Copper PCB features an impressive 2 Layer configuration, reflecting the standard sophistication in PCB fabrication. The dual-layer approach enables this board to accommodate a more complex circuitry within a compact space, whilst maintaining a clear signal pathway. Each layer in this PCB is enriched with a substantial copper thickness, typically ranging from 3-10OZ. This Copper-Infused PCB is tailored to sustain high-current circuits without the risk of overheating or circuit failure, thereby ensuring a stable and efficient electronic performance.

A standout feature of the Heavy Copper PCB is its meticulous 100% Testing protocol. Every single board is subjected to a comprehensive suite of tests designed to guarantee its functionality, integrity, and reliability. This testing ensures that each PCB meets stringent quality standards, leaving no room for errors or inconsistencies. Customers can trust in the unwavering quality of this product, knowing that each Print Circuit Board has been rigorously scrutinized and validated for optimum performance.

The aesthetic appeal of the Heavy Copper PCB is heightened by its striking blue Solder Mask. This protective layer not only adds to the visual appeal of the board but also serves a critical function in safeguarding the copper traces against oxidation, environmental contaminants, and potential short-circuits. The solder mask also facilitates easier soldering of components, contributing to the overall reliability and longevity of the board.

Compliance with international trade standards is evident in the Heavy Copper PCB's adherence to the HS Code: 8534009000. This harmonized system code categorizes the board within the realm of electrical machinery and equipment, specifically indicating its status as a printed circuit board. This classification is essential for smooth import and export operations, ensuring that the Heavy Copper PCB is recognized globally for customs and trade purposes.

In the ever-evolving electronic industry, the demand for robust and high-performance PCBs is paramount. The Heavy Copper PCB is an outstanding response to this demand, offering a 3-10OZ PCB that can withstand the rigors of high-power and high-temperature applications. Its two-layer design, dedicated to high-current conductance and dissipation, positions this PCB as an ideal choice for industries such as automotive, power supply systems, solar panels, and heavy machinery controls.

In conclusion, the Heavy Copper PCB is a testament to the relentless pursuit of excellence in the PCB manufacturing industry. It encapsulates the strength, precision, and reliability required for advanced electronic applications. With its 100% Testing assurance, vibrant blue Solder Mask, and compliance with HS Code: 8534009000, customers can be confident in selecting a Print Circuit Board that is not only functionally superior but also meets the highest standards of quality and regulatory compliance. The Heavy Copper PCB is indeed the substrate of choice for those who seek unmatched performance in challenging electrical environments.

Features:

- Product Name: Heavy Copper PCB

- Pcb Test: 100% Testing

- Standard: IPC-A-610 Class II-III

- Minimum Line Space: 3mil (0.075mm)

- Process: Immersion Gold/Silver

- Copper Thickness: 6-10 OZ

- Copper-Clad PCB

- Copper-Infused PCB

- Copper Heavy Duty PCB

Technical Parameters:

| Attribute |

Details |

| Number Of Layers |

2 Layer |

| Process |

Immersion Gold/Sliver |

| Copper Thickness |

6-10 OZ |

| Layer Count |

2 |

| Min Hole Size |

0.2MM |

| Pcb Test |

100% Testing |

| Hs Code |

8534009000 |

| Solder Mask |

Blue |

| Pcb Standard |

IPC-II Standard |

| Minimum Line Space |

3mil (0.075mm) |

Applications:

The Heavy Copper PCB, characterized by its robust copper thickness ranging from 6 to 10 OZ, is designed for applications where superior current-carrying capacity and thermal management are imperative. With a board size of 6*9cm, this Copper-Enriched PCB is compact yet powerful, ensuring a seamless fit into a wide array of electronic products. The PCB test guarantees a 100% testing protocol, ensuring that each board meets the high-quality standards required for reliable and stable performance in demanding environments.

One key application occasion for the Heavy Copper Printed Circuit Board (PCB) is in industrial power electronics, where the boards are subject to high power and thermal loads. The increased copper thickness allows for efficient heat dissipation, ensuring that devices operate within their optimal temperature range and prolonging their lifespan. In the automotive industry, these Copper-Rich PCBs are essential in electric vehicle (EV) controllers and power converters, providing the robustness needed to handle high power surges and fluctuations typical of automotive electrical systems.

The immersion gold/sliver process employed in the manufacturing of these heavy copper PCBs offers excellent surface planarity and a reliable surface for component soldering. This makes them ideal for high-density applications found in the military and aerospace sectors where precision and reliability are non-negotiable. In such scenarios, the solder mask thickness, which ranges from 20-50UM, provides an additional layer of protection against environmental stress and mechanical damage.

Moreover, the Heavy Copper PCB can be used in solar power inverters, where the enhanced ability to carry higher currents is crucial for the conversion efficiency of solar energy into electrical power. Additionally, high-end audio equipment often utilizes these heavy copper boards for their superior power handling and reduced impedance variation, which contribute to clearer and more precise sound reproduction.

In summary, the Heavy Copper Printed Circuit Board, with its generous copper thickness, meticulous 100% testing, and premium processing including immersion gold/sliver, is the PCB of choice for applications that demand high power density, thermal endurance, and unwavering reliability. Its broad application scenarios underscore its versatility and the critical role it plays in powering and protecting advanced electronic systems across various demanding industries.

Customization:

HS Code: 8534009000

Standard: IPC-A-610 Class II-III

Copper Thickness: 6-10 OZ

Production Name: Print Circuit Board

Application: Medical Instruments

Our Heavy Copper PCB products, catering to specialized applications, offer a range of product customization services. Known for their durability and reliability, our Copper-Rich PCBs are ideal for high-power distribution and heat dissipation. The Copper Heavy Duty PCBs we manufacture can withstand extreme environmental conditions, making them suitable for demanding medical instrument applications. Additionally, our Copper-Infused PCBs are designed to meet the rigorous standards of IPC-A-610 Class II-III, ensuring performance and quality for your critical needs.

Support and Services:

Our Heavy Copper PCB product line is backed by comprehensive technical support and services designed to ensure that you get the most value out of your PCBs. Our product technical support includes dedicated assistance from our team of experienced engineers who can provide guidance on PCB design, material selection, and layout optimization for high-current applications. We also offer thermal management consulting to ensure your PCBs maintain reliability under strenuous conditions.

In addition to technical support, we provide a range of services to facilitate the smooth integration of Heavy Copper PCBs into your projects. This includes prototype development assistance, where we help you quickly turn your concepts into testable models, and small-to-large volume production support, ensuring scalability for your project's growth. Our PCB testing services are rigorous, ensuring that each board meets stringent quality and performance standards before deployment.

For clients requiring specialized solutions, we offer custom support packages which can include extended warranties, on-site training, and priority response for troubleshooting and issue resolution. Our goal is to provide you with the confidence that your Heavy Copper PCBs will perform to the highest standards throughout their lifecycle.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!