Product Description:

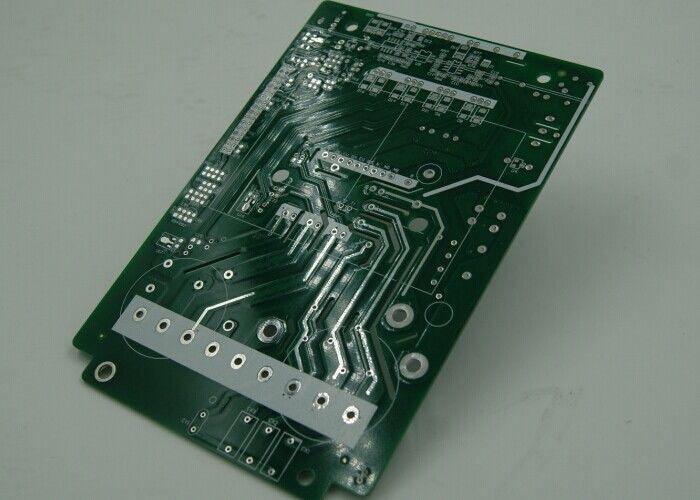

The Heavy Copper PCB product is an exceptional offering in the market of Copper-Laden PCBs, designed to cater to the rigorous demands of power electronics and advanced electrical applications. This PCB is distinctive for its robust construction and enhanced capacity for handling high current loads, thanks to its significant copper thickness that ranges from 6 to 10 OZ. Crafted meticulously to ensure reliability and durability, this board is not just an ordinary PCB, but a foundation that supports the most demanding electrical components and systems.

One of the key attributes of this Thick Copper PCB is its minimum hole size, which is as precise as 0.2MM. This feature is critical for creating fine pitch patterns necessary for modern electronic devices that require high-density component placements. The precision in the hole size allows for enhanced connectivity and functionality, which is vital for the performance of the PCB in various applications.

The manufacturing process of this Heavy Copper Printed Circuit Board (PCB) employs the advanced technique of Immersion Gold/Silver. This process ensures a thin layer of gold or silver is evenly applied over the copper surface, which not only provides a robust and reliable electrical connection for the components but also contributes to the longevity of the PCB by preventing oxidation. The immersion process guarantees that the surface finish is of the highest quality, which is critical in maintaining the integrity of signal transmissions.

With a substantial copper thickness, this PCB is designed to facilitate the conduction of high currents, distribute heat effectively, and withstand thermal strains. The use of 6 to 10 OZ of copper in the PCB’s construction is a testament to its ability to perform under extreme conditions. This attribute also allows the PCB to support heavier components and endure the mechanical stresses that can occur during the operation of high-powered electronics.

The board size of 6*9cm is thoughtfully selected to provide a compact yet ample working area for a variety of applications. This size is ideal for both prototyping and mass production, ensuring that the PCB can be utilized in diverse electronic devices. From industrial power converters to automotive power systems, this PCB size is versatile and can be seamlessly integrated into different setups.

A critical specification for any PCB is the minimum line width, which for this product stands at 3mil (0.075mm). This exceptionally narrow line width allows for high-density layouts, which is paramount for today's miniaturized electronic devices. Narrower lines mean more lines per unit area, and thus, more pathways for electrical signals, which translates to better performance and scalability for complex circuit designs.

In summary, the Heavy Copper PCB product is a robust, versatile, and high-performance solution for various electronic applications requiring a Thick Copper PCB. Its fine minimum hole size, advanced Immersion Gold/Silver process, substantial copper thickness, optimal board size, and precise minimum line width make it a highly sought-after product in the electronics industry. Whether for industrial-grade applications or sophisticated consumer electronics, this Heavy Copper Printed Circuit Board (PCB) is engineered to deliver unmatched performance and reliability.

Features:

- Product Name: Heavy Copper PCB

- Minimum Line Space: 3mil (0.075mm)

- Process: Immersion Gold/Silver

- Copper Thickness: 6-10 OZ

- Production Name: Print Circuit Board

- Pcb Test: 100% Testing

- Keywords:

- Copper Heavy Duty PCB

- Thick Copper PCB

- Copper-Clad PCB

Technical Parameters:

| Parameter |

Specification |

| Production Name |

Print Circuit Board |

| Package |

Carton + Binding Tape |

| Copper Thickness |

6-10 OZ |

| Solder Mask Thickness |

20-50UM |

| Solder Mask |

Blue |

| Board Size |

6*9cm |

| Standard |

IPC-A-610 Class II-III |

| Min Hole Size |

0.2MM |

| Number Of Layers |

2 Layer |

| Process |

Immersion Gold/sliver |

Applications:

The Heavy Copper PCB, adhering to the IPC-II Standard, is a highly durable and reliable product designed for use in a variety of robust applications. With a process that includes Immersion Gold/Silver, this PCB guarantees top-notch conductivity and a reliable finish, conforming to the stringent standards of IPC-A-610 Class II-III. The HS Code for this product is 8534009000, and it comes in a board size of 6*9cm, making it versatile for various installations.

Applications of the Heavy Copper PCB commonly include industrial controls where a Copper-Laden PCB can withstand high current loads and ensure the safety and longevity of the electronic system. This type of PCB is particularly beneficial in power electronics where High Copper Content PCBs are essential for efficient heat dissipation, reducing thermal strain on components and enhancing performance in harsh environments.

Another scenario where Copper-Enriched PCBs are invaluable is in automotive systems. With vehicles increasingly relying on electronic systems for functionality and safety, the Heavy Copper PCB provides the robustness required to handle vibrations, thermal cycling, and high currents, meeting the automotive industry's rigorous standards.

Military and aerospace applications also benefit greatly from the Heavy Copper PCB. The exceptional thermal management and high current handling capabilities are crucial for the reliability of communication systems, power distribution networks, and critical flight controls. The adherence to IPC-A-610 Class II-III standards ensures that these PCBs can survive the extreme conditions of military and aerospace operations.

In the field of renewable energy, Heavy Copper PCBs are often used in solar power inverters, wind power generators, and high-power rectifiers. The high copper content allows for the efficient transfer of power with minimal losses, which is fundamental in optimizing the performance of renewable energy systems.

Lastly, medical devices that require precise energy distribution for diagnostics or treatment can utilize Heavy Copper PCBs for their reliable performance and adherence to safety standards. The combination of IPC-II Standard compliance and the robust construction means these PCBs can be trusted in the sensitive and demanding realm of medical technology.

In conclusion, the Heavy Copper PCB product, with its robust features and versatile applications, is ideal for any scenario that demands high reliability, excellent thermal management, and the ability to handle substantial current loads.

Customization:

Our Weighty Copper PCB customization services adhere to the rigorous IPC-A-610 Class II-III standard, ensuring top-tier quality and reliability for your Heavy Copper Printed Circuit Board (PCB) needs. With advanced capabilities to accommodate a Min Hole Size of 0.2MM, we provide precision engineering to meet your exact specifications.

Experience the durability and superior performance of our Copper-Clad PCB with a robust Solder Mask in Blue, designed to protect your circuitry and enhance its longevity. We are committed to precision, offering a Minimum Line Space of 3mil (0.075mm), allowing for intricate designs and high-density connections.

To further ensure the resilience of your PCB, we apply a Solder mask thickness ranging from 20-50UM, giving your Heavy Copper PCB the extra defense against environmental factors and mechanical stresses. Choose our product customization services for a PCB that stands the test of time.

Support and Services:

We are committed to providing comprehensive technical support and services for our Heavy Copper PCB products. Our team of experienced engineers and technical specialists is available to assist with product inquiries, troubleshooting, and performance optimization to ensure your Heavy Copper PCBs meet your specific needs and industry standards.

Our services include, but are not limited to, assistance with design layout, material selection, thermal management, and stack-up recommendations. We also offer guidance on Heavy Copper PCB manufacturing processes to optimize for reliability and durability in demanding applications.

To support your development and maintenance efforts, we provide detailed documentation, including technical datasheets, application notes, and best practice guidelines. Our goal is to help you reduce design cycle times, minimize costs, and achieve the highest quality and performance from your Heavy Copper PCBs.

If you encounter any issues or have questions regarding our Heavy Copper PCBs, our support team is dedicated to resolving your concerns with prompt and actionable solutions. We strive for continuous improvement and welcome feedback on our products and support services to better serve your needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!