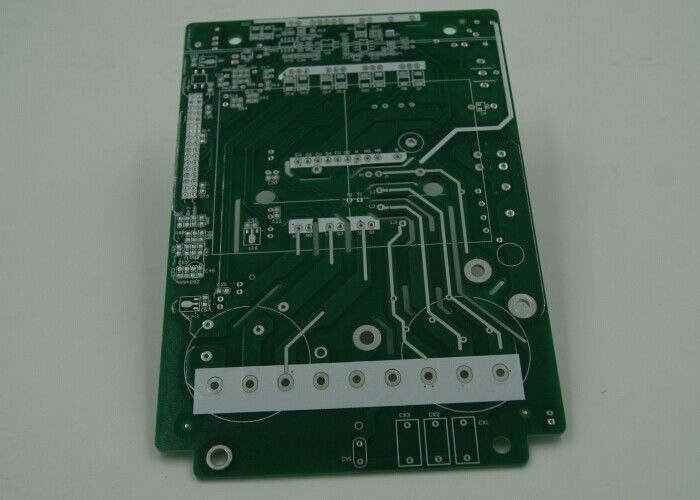

Medical Grade Heavy Copper PCB with 3mil Minimum Line Space 3mil Minimum Line IPC II Standard

Product Description:

The Heavy Copper PCB is a premium-grade printed circuit board that is specifically designed to cater to applications requiring high power distribution, increased current carrying capacity, and superior heat dissipation. This PCB type is distinguished by its heavy copper-infused layers that significantly enhance the board's performance, particularly in demanding electrical environments. The Heavy Copper PCB is constructed in compliance with the IPC-II standard, ensuring that it meets the rigorous requirements for performance, durability, and reliability.

One of the standout features of the Heavy Copper PCB is its substantial copper thickness, which allows it to support a higher current flow compared to standard PCBs. This makes the Copper Heavy Duty PCB an ideal choice for industrial applications, high-power distribution systems, and automotive electronics where robustness and longevity are paramount. The heavy copper layers also contribute to improved thermal management, enabling the PCB to withstand the thermal stresses of high-speed and high-frequency operations without compromising its structural integrity.

With an Hs Code of 8534009000, the Heavy Copper PCB is categorized under the harmonized system code for printed circuits, which serves as a benchmark for international trade and tariff classification. This designation ensures that the product adheres to global trade compliance standards and facilitates smooth import and export processes for clients worldwide.

Attention to detail is evident in every aspect of the Heavy Copper PCB's design, including the precision drilling of holes. With a minimum hole size of just 0.2MM, the PCB can accommodate a variety of electronic components with fine pitch, enabling designers to create more complex and compact circuits without compromising on connectivity or performance. This feature is particularly beneficial for advanced electronic assemblies where space is at a premium.

Moreover, the Heavy Copper PCB boasts an impressive minimum line width of 3mil (0.075mm), allowing for tighter trace spacing and higher conductivity. This copper-laden PCB is capable of supporting dense component layouts while maintaining excellent signal integrity and reducing the risk of short circuits. The narrow line width is a testament to the advanced manufacturing processes employed in the fabrication of these high-quality PCBs, which are designed to accommodate the intricate circuitry required by modern electronics.

When it comes to packaging, the Heavy Copper PCB is delivered with utmost care to ensure its pristine condition upon arrival. Each PCB is packaged in a sturdy carton and secured with binding tape, providing ample protection against physical impacts and environmental factors during transportation. This packaging method has been carefully chosen to prevent damage to the delicate copper traces and component mounting sites, guaranteeing that the PCBs are ready for immediate use upon delivery.

In summary, the Heavy Copper PCB is a robust and reliable solution for applications that demand high electrical performance and exceptional thermal management. By incorporating heavier copper layers into the board, this copper-infused PCB offers enhanced current carrying capacity, improved durability, and superior heat dissipation characteristics. Adhering to the IPC-II standard and featuring advanced manufacturing specifications such as a minimal hole size of 0.2MM and a minimum line width of 3mil, this copper-laden PCB stands out as a top-tier option for demanding electronic applications. Carefully packaged for optimal protection, the Heavy Copper PCB represents the pinnacle of PCB design and manufacturing excellence.

Features:

- Product Name: Heavy Copper PCB

- Number Of Layers: 2 Layer

- PCB Standard: IPC-II Standard

- Board Size: 6*9cm

- Minimum Line Space: 3mil (0.075mm)

- Package: Carton + Binding Tape

- Heavy Copper Printed Circuit Board (PCB)

- Copper-Laden PCB

Technical Parameters:

| Attribute |

Detail |

| Hs Code |

8534009000 |

| Minimum Line Width |

3mil (0.075mm) |

| Board Size |

6*9cm |

| Standard |

IPC-A-610 Class II-III |

| Solder mask thickness |

20-50UM |

| Number Of Layers |

2 Layer |

| Application |

Medical Instruments |

| Pcb Test |

100% Testing |

| Solder Mask |

Blue |

| Layer Count |

2 |

Applications:

The Copper Heavy Duty PCB, also known as a Heavy Copper PCB, is a robust and durable printed circuit board designed to meet the stringent requirements of high-power distribution and heat dissipation. These PCBs are ideally suited for medical instruments, where reliability and performance are critical. The heavy copper traces and planes enable the PCB to conduct higher currents, withstand extreme thermal strains, and provide a strong mechanical attachment to various components.

In the realm of medical instruments, the Copper-Infused PCB is a valuable component. Application scenarios include high-precision diagnostic equipment, such as MRI machines, CT scanners, and X-ray devices. These instruments require PCBs that can handle high power levels without failing, as any system malfunction could lead to incorrect diagnosis or even pose risks to patient safety. The Heavy Copper PCB ensures that medical devices operate with a high degree of stability and safety, thanks to its enhanced current-carrying capacity and thermal management.

When it comes to production standards, these Copper-Laden PCBs adhere to the IPC-A-610 Class II-III standards. This means that they meet the accepted requirements for high-performance electronic products, which include medical equipment. The production name, Print Circuit Board, signifies a level of quality and precision in manufacturing, which is essential for the delicate and life-sustaining applications these medical instruments serve.

Each Copper Heavy Duty PCB undergoes 100% testing to guarantee that every unit functions correctly before being deployed in any medical instrument. This rigorous testing protocol ensures that the product is free of any defects and meets the necessary electrical performance requirements. The minimum line space of 3mil (0.075mm) allows for high-density designs, which is imperative in compact medical devices where space is at a premium and every millimeter counts for achieving the complex functionality required in medical applications.

Overall, the Heavy Copper PCB product is the backbone of many critical medical instruments. It provides the necessary performance and reliability in a wide range of scenarios - from emergency room critical care devices to long-term patient monitoring systems. As medical technology evolves and the demand for sophisticated medical equipment increases, the Copper Heavy Duty PCB will continue to be an indispensable part of the healthcare industry's efforts to improve patient outcomes and enhance the capabilities of medical diagnostics and treatment.

Customization:

Our Copper-Laden PCB services adhere to the rigorous IPC-II Standard, ensuring that your heavy-duty PCB needs are met with the highest quality and reliability. We offer customization for your PCB, with a standard board size of 6*9cm, perfect for a variety of applications.

Engineered to facilitate high-current applications, our Copper Heavy Duty PCB is designed with precision, featuring a minimum line space of 3mil (0.075mm). This allows for intricate circuit designs while maintaining the robustness required for demanding environments.

The 3-10OZ PCB process includes Immersion Gold/Silver, providing a durable and conductive surface that enhances the performance of your heavy copper PCB. This process ensures a long-lasting connection and superior performance for your electronic components.

We specialize in heavy copper PCBs with a copper thickness ranging from 6-10 OZ. This capability allows us to cater to your specific needs, whether you're looking for robust power distribution or heavy-duty electronic applications.

Support and Services:

The Heavy Copper PCB product comes with comprehensive technical support and services to ensure maximum performance and reliability. Our support includes:

Design Consultation: Our team of experienced engineers is available to assist with PCB design and layout, ensuring that your Heavy Copper PCB is optimized for your specific application.

Material Selection Guidance: We help you choose the most suitable materials for your Heavy Copper PCB to meet your thermal management, reliability, and durability requirements.

Manufacturing Process Oversight: We monitor every step of the manufacturing process to ensure that your PCBs meet our strict quality standards. This includes careful inspection of the heavy copper features for proper adhesion and integrity.

Testing and Quality Assurance: Every Heavy Copper PCB undergoes rigorous testing to ensure functionality and compliance with industry standards. Our quality assurance team works diligently to identify and rectify any issues before shipment.

After-Sales Support: Once your Heavy Copper PCB is in use, our team remains available to provide any assistance needed, from troubleshooting to advice on best practices for maintenance and handling.

Documentation and Resources: Full documentation is provided with each Heavy Copper PCB, including technical specifications, handling instructions, and safety guidelines to ensure proper usage and longevity of the product.

Customization Services: Should you require any modifications or custom features for your Heavy Copper PCB, our services include custom engineering to meet your unique requirements.

Our commitment to excellence in product support and services ensures that you can rely on our Heavy Copper PCBs for high-power distribution, heat dissipation, and robust performance in the most demanding applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!