Product Description:

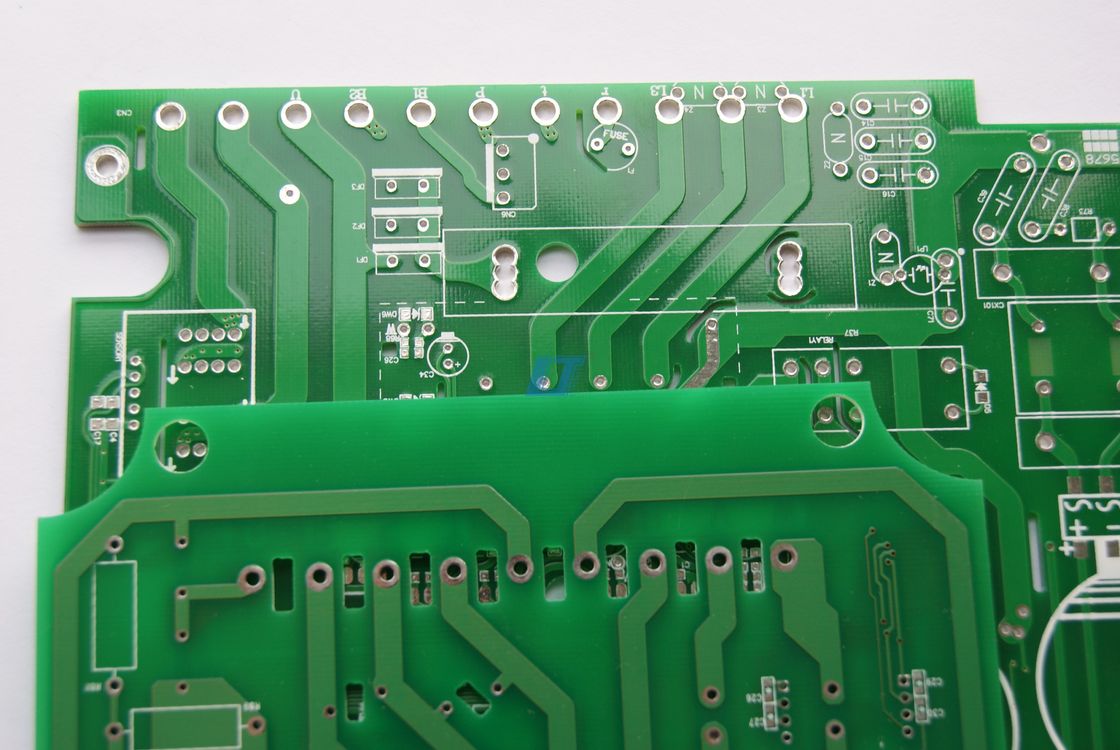

The Heavy Copper PCB, also known as Copper-Enriched PCB, Copper-Laden PCB, or Copper-Clad PCB, is a robust and high-quality Print Circuit Board designed to meet the rigorous demands of high-power distribution and heat dissipation. This product is meticulously engineered to provide unparalleled performance in a variety of applications, including industrial controls, power electronics, automotive systems, and more. Each PCB is securely packaged in a durable carton and further stabilized with binding tape to ensure that it arrives to customers in pristine condition, free from damage and ready for use.

One of the standout features of this Heavy Copper PCB is its impressive minimum line width of just 3mil (0.075mm), which allows for a higher density of circuits per unit area. This fine line resolution is a testament to the advanced manufacturing capabilities employed in the production of these PCBs, enabling designers to create more complex and compact circuits without compromising on performance or reliability. The precise line width control is essential for high-frequency and high-speed electronic applications where signal integrity is paramount.

To enhance the durability and lifespan of the PCB, a solder mask with a thickness ranging from 20-50UM is applied to the board. This layer serves multiple purposes: it insulates the copper traces to prevent accidental contact and short circuits, it protects the board from environmental contaminants, and it can withstand the high temperatures associated with soldering processes. The thickness of the solder mask is carefully calibrated to balance protection with the need for fine-feature resolution, ensuring that the PCB can handle demanding applications while maintaining its precise circuitry intact.

The process used to manufacture the Heavy Copper PCB includes Immersion Gold/Silver, which is a surface finish technique that provides a flat and conductive surface that is excellent for wire bonding and soldering. Immersion Gold provides a dense, hard surface that resists oxidation and maintains its conductivity over time, while Immersion Silver offers a cost-effective alternative with good conductivity and a surface that is also resistant to tarnishing. Both finishes contribute to the reliability and long-term performance of the PCB, making them ideal for applications where consistent electrical properties are essential.

As a Copper-Enriched PCB, this product boasts a substantial copper weight, enabling it to carry higher currents, withstand greater thermal loads, and exhibit increased mechanical strength compared to standard PCBs. This makes it particularly suitable for applications that require heavy power distribution or heat sinking capabilities. The increased copper thickness also improves the thermal conductivity of the PCB, allowing for more effective heat dissipation, which is crucial for maintaining optimal performance and preventing overheating in high-power applications.

The Copper-Laden PCB is also designed for ease of assembly and integration into various systems. The compatibility with standard soldering techniques, along with the robustness provided by the thick solder mask and precise surface finishes, ensures that assembly processes are smooth and yield high-quality results. This is particularly important in automated manufacturing environments, where consistency and reliability are key to maintaining high throughput and reducing waste.

Finally, the Copper-Clad PCB is not just a component; it's a foundation upon which powerful and efficient electronic systems are built. Its premium materials, advanced manufacturing processes, and stringent quality control measures all contribute to a product that performs reliably under the most demanding conditions. Whether you're developing cutting-edge electronics or looking for a dependable solution for power distribution, the Heavy Copper PCB is engineered to exceed your expectations and deliver unmatched performance.

Features:

- Product Name: Heavy Copper PCB

- Number Of Layers: 2 Layer

- PCB Test: 100% Testing

- Board Size: 6*9cm

- Minimum Line Width: 3mil (0.075mm)

- Copper Thickness: 6-10 OZ

- Copper-Infused PCB for enhanced conductivity

- Copper Heavy Duty PCB designed for high current applications

- Durable Copper Heavy Duty PCB with increased thermal resistance

Technical Parameters:

| Parameter |

Specification |

| Layer Count |

2 |

| Solder Mask |

Blue |

| Package |

Carton + Binding Tape |

| Min Hole Size |

0.2MM |

| Production Name |

Print Circuit Board |

| Pcb Standard |

IPC-II Standard |

| Copper thickness |

6-10 OZ |

| Pcb Test |

100% Testing |

| Board Size |

6*9cm |

| Number Of Layers |

2 Layer |

Applications:

The Heavy Copper PCB, particularly known for its robust construction, is an integral component in various applications where high current or high thermal conductivity is a prerequisite. With a minimum hole size of 0.2MM and a configuration of 2 layers, this Copper Heavy Duty PCB is designed to withstand the rigors of extreme operational conditions. The use of a blue solder mask not only provides a distinct visual identification but also contributes to its durability and resistance to soldering stresses.

Packaged meticulously in cartons with binding tape, the Heavy Copper PCB ensures secure delivery and handling, safeguarding its integrity from the manufacturing facility to the application site. The harmonization system (HS) code of 8534009000 is a testament to its classification and standardization in global trade, enabling seamless transactions and compliance with international trade laws.

Ideal for power electronics and industrial applications, the Copper-Enriched PCB is commonly utilized in power supply systems, automotive electronics, and heavy machinery controls. Its capability to carry higher currents makes it a perfect fit for applications such as high-current battery chargers, power distribution panels, and welders that require a 3-10OZ PCB to manage substantial power loads without compromising the integrity of the circuit.

Moreover, the thermal management properties of the Heavy Copper PCB make it an excellent choice for heat dissipation applications. It can be found in cooling systems, heat exchangers, and HVAC systems, where the robustness of the copper traces is essential to handle the thermal strains. The enhanced copper thickness not only provides improved electrical performance but also contributes significantly to the mechanical strength of the board, making it suitable for scenarios where mechanical stresses are a concern.

In summary, the Heavy Copper PCB is a versatile and durable solution for applications requiring high power density and superior thermal management. Its blue solder mask, secure package, precise minimum hole size, and dual-layer configuration, combined with its compliance with the HS code 8534009000, make it an optimal choice for a broad spectrum of industries seeking reliability and performance in their electronic components.

Customization:

Solder Mask Thickness: Our Heavy Copper PCBs come with a solder mask thickness ranging from 20-50UM, ensuring robust protection and durability for your applications.

Application: Specifically designed for Medical Instruments, our PCBs meet the rigorous standards required for medical equipment, providing reliability where it matters most.

PCB Test: To guarantee performance, each of our PCBs undergoes 100% Testing, ensuring that every unit meets our high-quality standards.

Solder Mask Color: Our Heavy Copper PCBs feature a striking Blue solder mask, providing a clear visual distinction and aiding in the inspection process.

Standard: Manufactured in compliance with IPC-A-610 Class II-III standards, our 3-10OZ PCBs represent the pinnacle of quality for Copper Heavy Duty PCB applications.

Support and Services:

Our Heavy Copper PCB products are supported by comprehensive technical support and services to ensure the highest quality and performance. Our team of experts is dedicated to providing you with the assistance you need throughout the lifecycle of your product. From design and layout recommendations to help with material selection and stack-up, we are here to assist you.

We offer a range of services to address any technical challenges you may encounter. This includes troubleshooting issues related to manufacturing processes, handling and storage practices, and end-use application performance. Our knowledge base, which is continually updated with the latest industry insights, is also at your disposal to provide you with valuable information and tips.

For assistance with optimizing your design for manufacturability and reliability, our technical support team is available to provide guidance. We can also help you understand the capabilities and limitations of Heavy Copper PCB technology to ensure that your design takes full advantage of the material's properties.

In addition to our support services, we provide detailed documentation and resources, including datasheets, technical guides, and application notes, to help you make informed decisions about using and maintaining your Heavy Copper PCB products.

Please note that our technical support does not extend to the repair or modification of existing PCBs or to the direct handling of electrical components. We recommend consulting with a qualified electronics technician for such services. Our team is focused on providing support related to the Heavy Copper PCB itself and its integration into your projects.

Our commitment to customer satisfaction means that we strive to respond promptly and effectively to all inquiries. We are dedicated to ensuring that you have all the support you need to successfully incorporate our Heavy Copper PCB products into your applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!