Product Description:

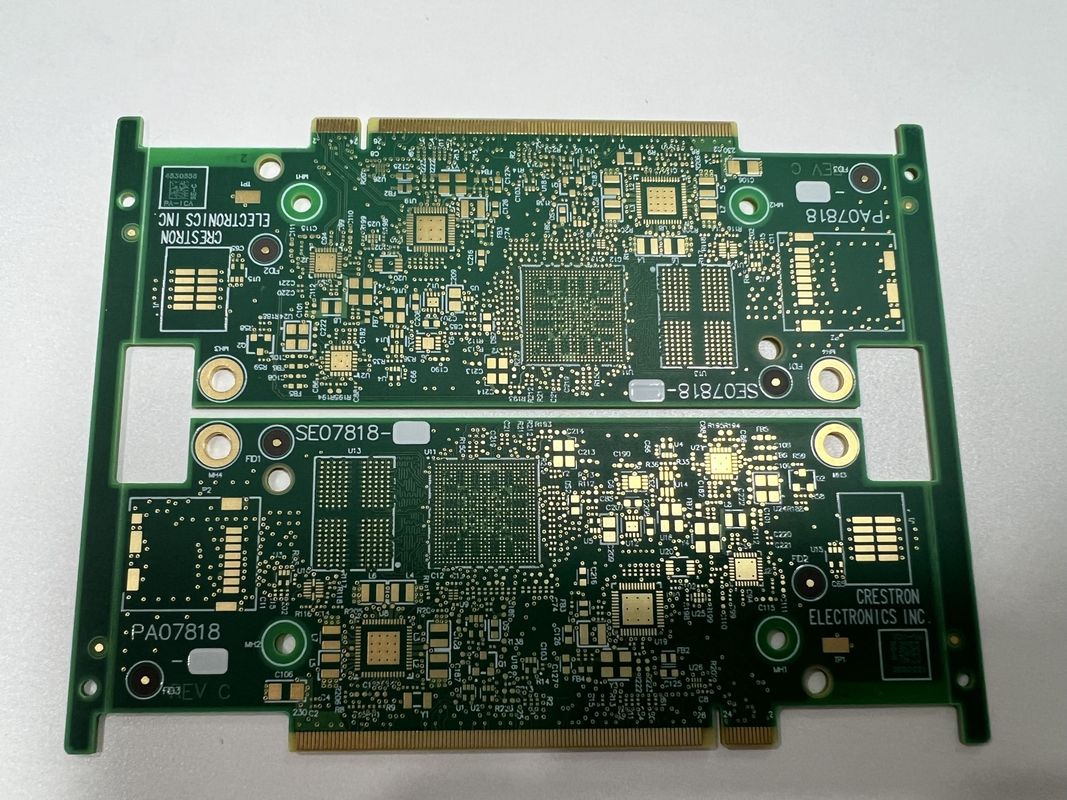

The High Density Interconnect (HDI) PCB Board is a pinnacle of modern PCB technology, embodying the latest advancements in circuit board manufacturing. This High Density Model Board is designed to meet the rigorous demands of today's complex electronic devices, which require miniature form factors without compromising on performance or connectivity. HDI PCB Boards are characterized by their denser wiring, smaller vias, and higher connection pad density than traditional PCBs, making them the go-to choice for high-performance electronics.

With a board layer count ranging from 6 to 32 layers, the HDI PCB Board offers tremendous flexibility and is capable of accommodating the intricate circuit designs inherent to multi-layer configurations. This versatility makes it suitable for a wide array of applications, from sophisticated consumer electronics to critical medical devices and high-grade military systems. The layer count directly corresponds to the complexity and functionality that can be achieved, allowing engineers to design highly advanced circuits that take advantage of the board's multi-layer structure.

Moreover, the HDI PCB Board comes in a variety of thicknesses, starting from a slender 0.2mm (8mil) and going up to a robust 6.00mm (126mil). This range ensures that the product can be tailored to specific requirements, whether that means a slim profile for lightweight, portable devices or a thicker board for durability and enhanced support for heavier components. The board thickness plays a crucial role in the overall mechanical stability of the final product, as well as its thermal management capabilities.

The exceptional aspect ratio of 10:1 is a testament to the precision engineering of the High Density PCB. This ratio is indicative of the board’s capacity to feature very small vias (holes) with large depth, a characteristic that is essential for multi-layer boards. Such a high aspect ratio is challenging to achieve and maintain, but it is crucial for the miniaturization of electronic components, allowing for more functionality to be packed into a smaller space.

Testing is a critical component in the manufacturing of any PCB, and the HDI PCB Board is no exception. To ensure the utmost quality and reliability, every board undergoes 100% E-Testing. This comprehensive electrical testing confirms the integrity of the board, verifying that all connections are correct and that there are no short circuits or open circuits. Additionally, X-RAY inspection is utilized to examine the internal features of the board, ensuring that the layers, vias, and hidden components are correctly positioned and free from defects. These rigorous testing protocols are in place to guarantee that each High Density PCB meets the high standards expected by customers in demanding fields.

For those in need of a High Density Model Board that combines high layer count, variable thickness, stringent testing standards, and an impressive aspect ratio, the HDI PCB Board is an unrivaled choice. It encapsulates the cutting-edge of PCB design and manufacturing, offering unparalleled density and connectivity for sophisticated electronic applications. With its robust construction, meticulous testing, and versatility, the HDI PCB Board stands as a premier product for any industry requiring high-performance and highly reliable circuit boards.

Features:

- Product Name: HDI PCB Board

- Testing: 100% E-Testing, X-RAY

- Raw Material: FR4 IT180

- Minimum Hole Size: 0.15mm

- Impedance Control: Yes

- Aspect Ratio: 10:1

- High Density PCB

- High Speed PCB Board

- High Density Interconnect PCB

Technical Parameters:

| Parameter |

Specification |

| Board Layer |

6-32L |

| Board Thickness |

0.2mm-6.00mm (8mil-126mil) |

| Thickness |

0.4-3.2mm |

| Raw Material |

FR4 IT180 |

| Key Words |

High Density Interconnector, DDR4 PCB, HD SDI Converter, HDI PCB |

| Aspect Ratio |

10:1 |

| Hole Size |

0.1mm Laser Drill |

| Minimum Hole Size |

0.15mm |

| Pcb Name |

4L 1+N+1 HDI Boards |

| Min Trace |

3/3Mil |

Applications:

The 4L 1+N+1 HDI Boards, with their versatile layer count ranging from 4 to 20 layers, and board thickness options stretching from 0.2mm to a robust 6.00 mm, are an embodiment of cutting-edge HDI PCB manufacturing. Utilizing FR4 IT180 as the raw material, these high-speed PCB boards are designed to meet the stringent standards of modern electronics, boasting a minimum trace width and spacing of 3/3mil, which enables them to support the high-density component placement that contemporary electronic devices require.

High-speed PCB boards like the 4L 1+N+1 HDI are crucial in applications where performance and space are at a premium. Smartphones, tablets, and laptops are quintessential examples of devices that benefit from the miniaturization and enhanced electrical performance that HDI PCB manufacturing offers. The compact and multi-layered nature of these boards allows for more functionality to be packed into the slim form factors that consumers demand. Whether it is for processing power, memory capacity, or integrated sensors, these HDI PCBs are up to the task.

In the realm of wearable technology, the high-speed PCB is equally vital. Devices such as smartwatches, fitness trackers, and medical monitoring systems rely on the compact, high-density interconnects that 4L 1+N+1 HDI Boards provide. The small trace and space, combined with the ability to integrate multiple layers, make these PCBs ideal for the sophisticated and miniaturized electronics found in wearables.

Moreover, in the field of industrial electronics, where reliability and precision are non-negotiable, the 4L 1+N+1 HDI Boards shine. They are used in complex industrial control systems, automation technology, and robotics. The robustness offered by the FR4 IT180 material ensures stability and durability, even in harsh industrial environments where high-speed PCBs are exposed to extreme temperatures, vibrations, and other challenging conditions.

The aerospace and defense sectors also harness the advantages of high-density interconnect PCBs. Military-grade communication devices, avionics, and satellite technology all require the reliability and high-speed signal transmission capabilities that these HDI boards provide. The combination of a high layer count and fine trace capabilities allows for sophisticated circuit designs that can operate effectively in the demanding scenarios faced by aerospace and defense equipment.

Lastly, in the automotive industry, the ongoing evolution towards more intelligent and connected vehicles necessitates the integration of HDI PCBs. Advanced driver-assistance systems (ADAS), infotainment systems, and onboard computers all benefit from the space-saving, high-performance characteristics of the 4L 1+N+1 HDI Boards. The ability to withstand the automotive environment's temperature fluctuations and vibrations, while maintaining high-speed signal integrity, makes these PCBs indispensable in modern vehicles.

In conclusion, the 4L 1+N+1 HDI Boards are at the forefront of HDI PCB manufacturing, offering unparalleled versatility and performance for a wide array of high-speed PCB applications across various demanding industries.

Customization:

Our HDI PCB Board is tailored to meet the intricate requirements of sophisticated electronic components such as the HD SDI Converter. With a High Density PCB design, our product ensures that your high speed PCB Board applications are supported by top-tier specifications. Our customization services include:

Min Trace: Precision etching capabilities allow for a minimum trace and space of 3/3Mil, accommodating the compact layouts necessary for High Density PCBs.

Raw Material: We utilize high-quality FR4 IT180 raw material to ensure the durability and performance consistency of your HDI PCB Board, making it ideal for High Speed PCB Board applications.

Aspect Ratio: Our HDI PCB Board boasts an impressive aspect ratio of 10:1, which is a testament to our advanced fabrication processes and is crucial for HD SDI Converter applications.

Impedance Control: Yes, impedance control is meticulously managed to ensure signal integrity, especially vital in High Speed PCB Board and HD SDI Converter designs.

Minimum Hole Size: Our High Density PCB technology allows for a minimum drilled hole size of 0.15mm, providing the precision required for the miniaturized components used in cutting-edge electronic assemblies.

Support and Services:

Our HDI PCB Board comes with comprehensive Product Technical Support and Services designed to ensure that your experience with our product is seamless and satisfactory. Our support includes access to a detailed online knowledge base, troubleshooting guides, and technical documentation to assist with any questions or issues that may arise during the use of our HDI PCB Board.

We provide a variety of services to support our HDI PCB Board, including but not limited to:

- Technical Inquiry Assistance: Our team of experts is available to help clarify any technical queries you may have regarding the specifications, capabilities, or integration of our HDI PCB Board into your projects.

- Firmware Updates: We offer regular firmware updates to enhance the functionality of your HDI PCB Board and to address any bugs or security vulnerabilities.

- Hardware Consultation: Should you encounter any hardware-related issues, our support team can guide you through diagnostic procedures to identify and solve the problem.

- Repair Services: In the event that your HDI PCB Board requires repair, we provide a streamlined process to ensure that your product is fixed and returned to you in a timely manner.

- Product Training: We offer training materials and sessions to help you and your team get the most out of the HDI PCB Board.

Our goal is to provide exceptional support and services to enhance your experience with our HDI PCB Board. Should you need any assistance, our dedicated support team is committed to providing you with the guidance and solutions you need to keep your operations running smoothly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!