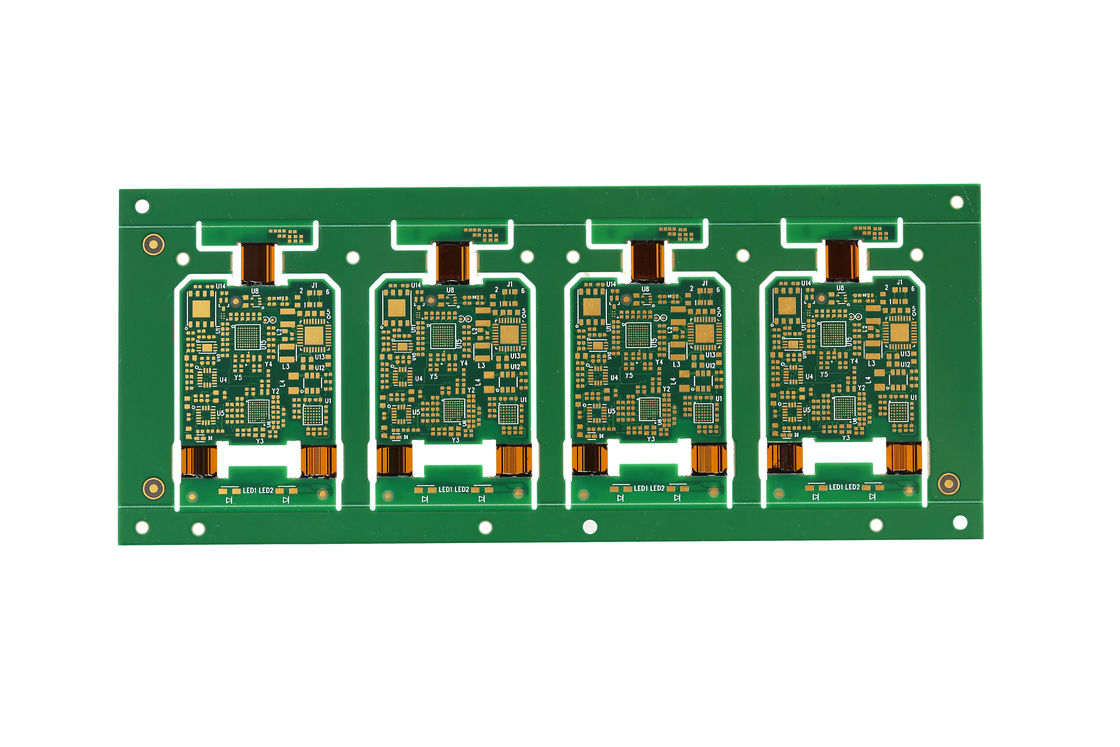

Density 52L Rigid Flex Pcb Assembly 4 Layer Enig Treatment 0.1Mm Trace Bend Radius 0.5-10Mm

Product Description:

The Rigid Flex PCB product is a state-of-the-art solution designed for advanced electronic applications that require the robustness of a traditional rigid PCB combined with the versatility of a flexible circuit. This hybrid circuit board is engineered to meet the high demands of modern electronics, making it an ideal choice for devices that require complex circuitry within a compact space. Our Rigid Flex PCB is manufactured with a commitment to quality and precision, ensuring a product that is not only reliable but also offers excellent electrical performance.

Constructed from high-quality materials such as FR4, Polyimide, and PET, our Rigid Flex PCBs are built to last. FR4 provides the rigid sections of the PCB with structural stability and impressive durability, while Polyimide and PET materials offer exceptional flexibility to the flex circuits. This combination allows the Flexible Rigid Circuit Board to withstand repeated bending and folding, making it perfectly suited for applications that require the circuit to conform to specific shapes or to move during operation.

Our product is defined as a PCB Assembly, which means it's not just a bare board but a comprehensive solution that includes the installation of various electronic components onto the rigid and flexible parts of the circuit board. The assembly process is handled with utmost precision and care, ensuring that each component is placed accurately for optimal performance. The Rigid Flex PCB assembly process is streamlined to meet high manufacturing standards, resulting in a product that is reliable and ready for immediate use in a wide range of applications.

Profiling and punching are critical steps in the manufacturing of a Flex-Rigid Printed Circuit Board. Our Rigid Flex PCBs are crafted with advanced techniques such as Routing, V-CUT, and Beveling. These processes are meticulously carried out to create clean and precise board edges and to facilitate easy separation of multiple boards when necessary. The beveling process, in particular, aids in the insertion of the PCB into connectors or other interfaces, reducing the risk of damage during assembly and ensuring a snug and secure fit.

Accuracy in hole positioning is vital for the integrity of any PCB, and our Rigid Flex PCBs have a remarkable hole position deviation tolerance of ±0.05mm. This high precision ensures that every hole is drilled exactly where it is needed, which is crucial for the proper fit of through-hole components and vias. This tight tolerance is indicative of the quality control processes in place throughout the manufacturing of our PCBs, which guarantee that each board meets the exact specifications required for sophisticated electronic devices.

Our Rigid Flex PCB is a 4 Layer construction, providing an optimal balance of complexity and usability. The multilayer design enhances the board's electrical properties, allowing for more circuits in a smaller area, reducing noise and interference, and increasing the overall durability of the PCB. The 4 Layer design is particularly beneficial for the Foldable Rigid Circuit Board application where space constraints are a challenge, and high-density interconnects are necessary.

In summary, our Rigid Flex PCB product stands out as an exceptional choice for applications that require the mechanical benefits of a flex circuit with the electrical functionality of a rigid board. Its construction from premium materials, combined with precise fabrication techniques such as Routing, V-CUT, and Beveling, and the stringent tolerance in hole positioning, makes it a versatile and dependable solution for a vast array of electronic needs. Whether you are looking for a Flexible Rigid Circuit Board, a Flex-Rigid Printed Circuit Board, or a Foldable Rigid Circuit Board, our product is designed to exceed expectations and deliver unmatched performance.

Features:

- Product Name: Rigid Flex PCB

- Pcb Layer: 1-28 layers

- Surface Finishing: HASL LF

- No Of Layers: 4 Layer

- Flexibility: 1-8 Times

- Minimum Trace/Space: 0.1mm

- Flexible Stiff Circuit Board

- Flex-Rigid Printed Circuit Board

- Rigid Flexible Printed Circuit Board

Technical Parameters:

| Attribute |

Specification |

| Components |

SMD, BGA, DIP, Etc. |

| Profiling Punching |

Routing, V-CUT, Beveling |

| Max Layer |

52L |

| Dimension |

41.55*131mm |

| Hole Position Deviation |

±0.05mm |

| Flexibility |

1-8 Times |

| Minimum Trace/Space |

0.1mm |

| Product Type |

PCB Assembly |

| Material |

FR4, Polyimide, PET |

| Bend Radius |

0.5-10mm |

Applications:

The Rigid Flex PCB, a sophisticated combination of rigidity and flexibility, is a Bendable Rigid Printed Wiring Board that has revolutionized the electronics industry. Composed of high-quality materials such as FR4, Polyimide, and PET, this product can cater to a wide range of applications, demanding both the sturdiness of traditional rigid PCBs and the adaptability of flexible circuits. With the capability to support up to a staggering 52 layers (52L), the Rigid Flex PCB is versatile and suitable for complex electronic assemblies.

One of the most crucial applications of the Rigid Flex PCB is in consumer electronics, where the Bendable Printed Circuit Board is used in smartphones, cameras, and wearable devices. These gadgets require components that can sustain bending and flexing during use or installation, while also maintaining a slim profile and high reliability. The Rigid Flex PCB, with its bendable nature, is an excellent choice for such devices, as it can be intricately folded or twisted to fit into small spaces without sacrificing performance.

In the field of aerospace and defense, the Rigid Flex PCB's ability to withstand extreme environmental conditions makes it ideal for use in satellites, military communication devices, and avionics. The combination of materials and the treatment options, like ENIG, OSP, Immersion Gold/Tin/Silver, along with Surface Finishing such as HASL LF, ensures that the PCB can endure the high-stress scenarios encountered in these sectors.

Medical devices also benefit greatly from the use of Rigid Flex PCBs. Equipment such as pacemakers, imaging systems, and portable diagnostic instruments need to be highly reliable and often require a Bendable Printed Circuit Board that can conform to specific shapes and sizes. The Rigid Flex PCB can seamlessly integrate into these applications, providing continuous and dependable operation thanks to its capability to house various components like SMD, BGA, DIP, and more, ensuring that life-saving technology operates flawlessly.

Moreover, the automotive industry utilizes Rigid Flex PCBs for their ability to save space and reduce weight in vehicle electronics. The Bendable Printed Circuit Board is perfect for in-vehicle systems, sensors, and control units, where it can be molded around mechanical features and within limited spaces, contributing to the overall efficiency and safety of the vehicle.

In summary, the Rigid Flex PCB product, with its robust material options, extensive layer support, diverse treatment, and surface finishing techniques, as well as its capacity to accommodate various electronic components, is an integral solution for numerous applications where flexibility and rigidity are requisite. Its usage spans across consumer electronics, aerospace, defense, medical, and automotive industries, demonstrating its versatility and essential role in advancing modern electronics.

Customization:

Our Flex-Rigid Printed Circuit Board customization services cater to a variety of specifications to meet your unique design requirements. With options for Sanforized Local High Density and Back Drill techniques, we ensure precision and reliability in the multi-layered construction of your Rigid Flex PCB product. Our capabilities extend from 1 to an impressive 28 layers of PCB, with a maximum layer count reaching up to 52L for the most complex projects.

Every Bendable Rigid Printed Wiring Board is tailored to exact dimensions, with the ability to craft boards at the specific size of 41.55*131mm. Whether you're looking for a standard PCB assembly or a more intricate arrangement, our product type customization ensures that your Flex-Rigid Printed Circuit Board is perfectly suited to your application, providing the flexibility and durability required for cutting-edge electronics.

Support and Services:

Rigid Flex PCB products combine the best of both rigid boards and flexible circuits integrated together into one unit. Our technical support and services for Rigid Flex PCBs include comprehensive guidance on design optimization, material selection, and layout recommendations to ensure high-quality performance and durability. We offer assistance in design for manufacturability (DFM) checks to identify potential production issues early in the design process, which can save time and reduce costs.

We also provide support for thermal management solutions, ensuring that your Rigid Flex PCBs maintain optimal performance under varying thermal conditions. Our team is equipped to help you understand the unique assembly and rework processes associated with Rigid Flex PCBs, minimizing the risks of damage during handling and assembly.

For any technical inquiries or issues, our dedicated support team is available to offer troubleshooting advice and to help resolve any challenges you may encounter with your Rigid Flex PCB products. We are committed to providing exceptional service to ensure your Rigid Flex PCBs meet your application requirements and exceed your expectations.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!