Product Description:

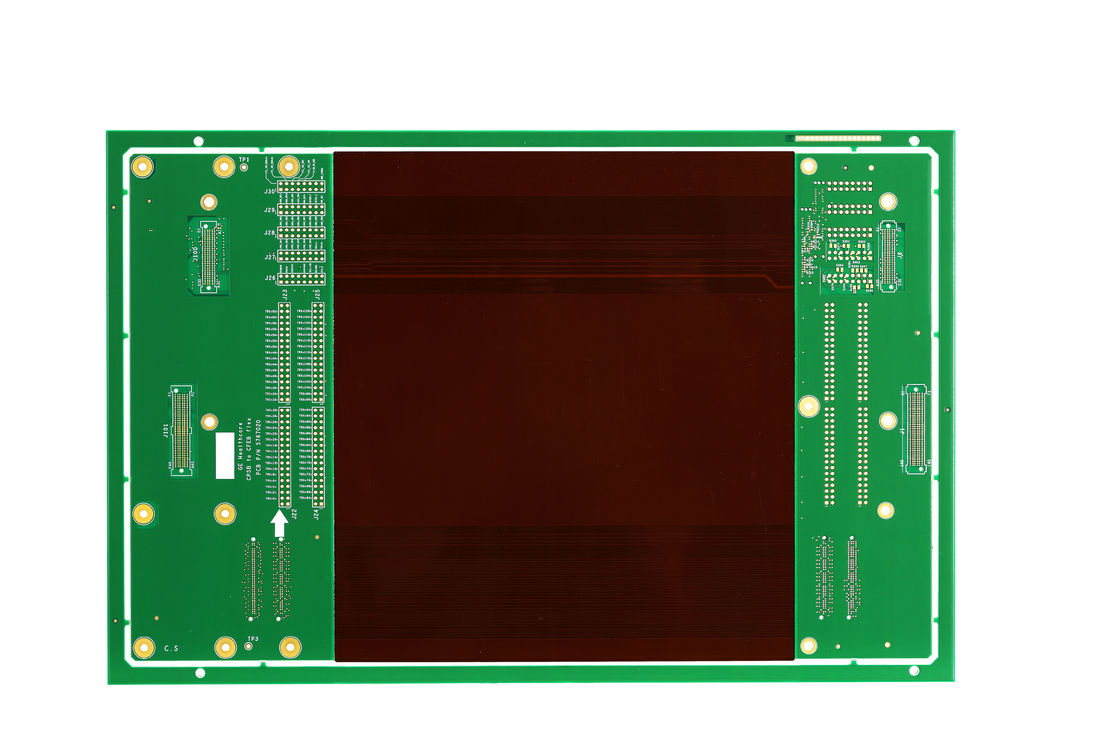

The Rigid Flex PCB product represents a remarkable fusion of the sturdiness of traditional rigid printed circuit boards (PCBs) and the versatility of flexible circuit technology. This hybrid solution, commonly referred to as a Flexible Rigid Circuit Board, is meticulously engineered to cater to the complex needs of contemporary electronic devices that require robustness without compromising on flexibility.

Our Rigid Flex PCB is tailored for PCB Assembly applications, where the integration of both rigid and flexible components is paramount. This integration is crucial for electronic manufacturers looking to optimize space, reduce weight, and enhance the reliability of their products. The Flexible-Bendable PCB technology is particularly beneficial in industries where electronic devices are subject to movement or bending, as it can withstand repeated flexing without failure.

One of the key attributes of our Rigid Flex PCB is its Surface Finishing, which utilizes HASL LF (Hot Air Solder Leveling Lead-Free). This environmentally friendly surface finish ensures excellent solderability and provides a level surface for component mounting, making it an ideal choice for high-reliability applications. HASL LF also offers a prolonged shelf-life for the PCBs, ensuring that they maintain their quality over time.

In the design of our Rigid Flexible Printed Circuit Board, the Bend Radius is a critical parameter. Our product boasts an impressive bend radius ranging from 0.5mm to 10mm, providing the flexibility needed for various applications while still maintaining the integrity of electronic connections. This feature is especially important for devices that require tight folding or that have to contour to specific shapes within an assembly.

Another standout characteristic of our Rigid Flex PCB product is the Minimum Trace/Space of 0.1mm. Such precision allows for high-density layouts, enabling more complex circuits to fit into smaller footprints. This miniaturization is a key advantage in modern electronics design, where the trend is towards making devices smaller, lighter, and more functional.

The Rigid Flex PCB also excels in precision with a Hole Position Deviation tolerance of ±0.05mm. This exceptional accuracy ensures that components and vias are perfectly aligned, which is essential for the reliability and performance of the final electronic assembly. This level of precision minimizes the risk of connection issues and ensures that the assembly process is smooth and efficient.

Our Flexible Rigid Circuit Board is designed and manufactured with the highest quality standards in mind. It undergoes rigorous testing and quality control procedures to ensure that it meets the stringent requirements of various industries, including aerospace, medical, military, and consumer electronics. The combination of flexibility, durability, and precision makes our Rigid Flex PCB the preferred choice for designers and engineers looking to push the boundaries of electronic device design.

To sum up, the Rigid Flex PCB product provides an optimal solution for modern electronic applications that demand the mechanical benefits of flexibility with the electrical performance of traditional rigid PCBs. With its HASL LF surface finish, customizable bend radius, precise trace and space capabilities, and stringent hole position deviation standards, it stands as a testament to cutting-edge PCB technology. Whether for intricate wearable devices, sophisticated medical equipment, or robust aerospace components, our Flexible-Bendable PCB is engineered to exceed expectations and drive innovation in the electronics industry.

Features:

- Product Name: Rigid Flex PCB

- Max Layer: 52L

- Dimension: 41.55*131mm

- Bend Radius: 0.5-10mm

- Surface Finishing: HASL LF

- Sanforized: Local High Density, Back Drill

- Also known as a Bendable Printed Circuit Board

- Can also be referred to as a Bendable Rigid Printed Wiring Board

- Flex Rigid PCB for advanced interconnection applications

Technical Parameters:

| Parameter |

Specification |

| Minimum Trace/Space |

0.1mm |

| Max Layer |

52L |

| Material |

FR4, Polyimide, PET |

| Treatment |

ENIG/OSP/Immersion Gold/Tin/Silver |

| Flexibility |

1-8 Times |

| Profiling Punching |

Routing, V-CUT, Beveling |

| Components |

SMD, BGA, DIP, Etc. |

| Surface Finishing |

HASL LF |

| Product Type |

PCB Assembly |

| Bend Radius |

0.5-10mm |

Applications:

The Rigid Flex PCB, composed of high-quality materials such as FR4, Polyimide, and PET, is a versatile and robust solution for a multitude of electronic applications. The product dimensions of 41.55*131mm, coupled with a precise hole position deviation of ±0.05mm, ensure a perfect fit and connectivity for complex assemblies. The PCB's bend radius ranges from 0.5 to 10mm, providing excellent flexibility while maintaining the structural integrity of the circuit. With the capability of supporting up to 52 layers, this Flexible Stiff Circuit Board is an engineering marvel suitable for advanced electronic systems.

Given its unique combination of rigidity and flexibility, the Rigid Flex PCB is ideal for dynamic applications where a Flexible-Bendable PCB is required. In the aerospace industry, these boards are particularly valuable for instrumentation and control systems that must withstand varying pressures and temperatures while maintaining a compact form factor. Similarly, in the automotive sector, the Bendable Rigid Printed Wiring Board is used for in-vehicle systems that require reliable performance despite constant vibrations and thermal cycling.

Consumer electronics also greatly benefit from the versatility of the Rigid Flex PCB. Portable devices such as smartphones, cameras, and wearable technology often utilize these boards for their ability to conform to space constraints without compromising on functionality. The Flexible Stiff Circuit Board can be seamlessly integrated into the sleek and ergonomic designs that modern consumers demand.

In the medical field, where reliability and precision are paramount, the Rigid Flex PCB is a critical component for diagnostic equipment, implants, and monitoring devices. Its ability to maintain consistent electrical performance while being able to bend to fit into irregular shapes makes it indispensable in this sector.

Military and defense applications also make use of the resilience and adaptability of these PCBs. Communication devices, ruggedized computers, and advanced weaponry systems require electronics that can survive extreme conditions and the Flexible-Bendable PCB is up to the task.

Lastly, the Bendable Rigid Printed Wiring Board is finding increasing use in the emerging field of flexible electronics, including foldable displays and next-generation wearables. The Rigid Flex PCB's robustness and adaptability make it the backbone of these innovative technologies.

Customization:

Our Flex Rigid PCB customization services cater to a variety of product attributes to meet your specific needs. Our Flexible Stiff Circuit Board manufacturing process ensures precise Hole Position Deviation of ±0.05mm, guaranteeing high-quality interconnections and alignment in your final product.

We offer a selection of materials for your Rigid Flex PCB including FR4, Polyimide, and PET, providing the flexibility to choose the best substrate for your application. As experts in PCB Assembly, we ensure that your product type specifications are meticulously met.

The Surface Finishing of our Flexible Stiff Circuit Boards is completed with HASL LF, presenting a reliable and cost-effective option for your assembly. Additionally, we provide various Treatment options like ENIG, OSP, Immersion Gold, Immersion Tin, and Immersion Silver to enhance the performance and longevity of your Flex Rigid PCB.

Support and Services:

Our Rigid Flex PCB products are supported by a comprehensive suite of technical support and services designed to ensure the highest level of performance, reliability, and customer satisfaction. Our expert team is dedicated to assisting you with any queries or challenges you may encounter with our products.

Technical Support Services include:

- Design Consultation: Our experienced engineers are available to provide guidance on Rigid Flex PCB design, materials selection, and layout optimization to meet your specific application requirements.

- Manufacturing Support: We offer support throughout the manufacturing process, including advice on stack-up options, impedance control, via structures, and surface finishes to ensure the highest quality product.

- Assembly Guidelines: To aid in the assembly process, we provide detailed guidelines on component placement, soldering techniques, and handling procedures to protect the integrity of the PCB during assembly.

- Testing and Quality Assurance: Our products undergo rigorous testing to ensure they meet all quality standards. Support is available to help interpret test results and implement any necessary improvements.

- Troubleshooting: If you encounter any issues with our Rigid Flex PCBs, our technical support team is ready to assist with troubleshooting to quickly identify and resolve any problems.

- Documentation and Resources: We provide a comprehensive library of technical documents, datasheets, and application notes to support the proper use and maintenance of our products.

Our commitment to excellence in customer service ensures that you have the support you need to successfully integrate our Rigid Flex PCBs into your projects. For any technical inquiries or support needs, please reach out to our customer service team (contact information excluded as per request).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!