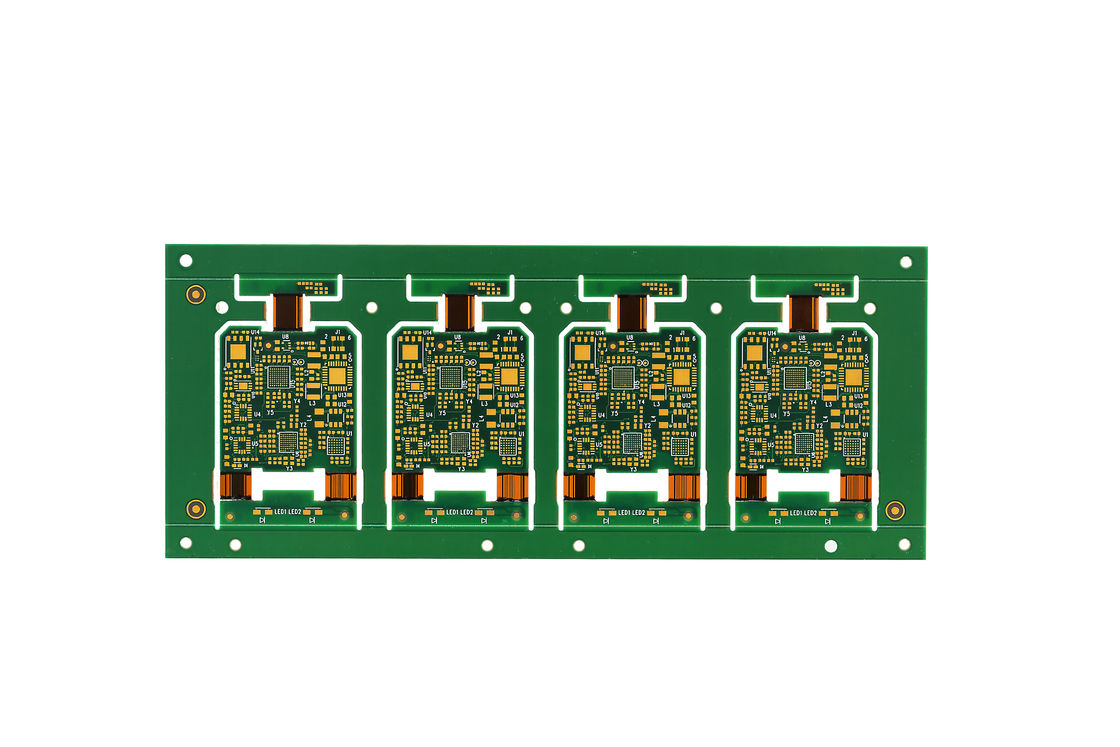

Flexibility Rigid Flex Pcb Local Density Hasl Lf Treatment Immersion Gold Finish 0.1Mm Trace/Space

Product Description:

The Rigid Flex PCB product represents a remarkable innovation in the field of electronic components, combining the best attributes of rigid printed circuit boards (PCBs) and flexible circuit technology. This cutting-edge product is designed to meet the evolving needs of modern electronics, where space constraints and functionality demand compact yet robust solutions. Our Rigid Flex PCB offers exceptional durability, reliability, and versatility, making it an ideal choice for a wide range of applications including aerospace, medical, automotive, and consumer electronics.

With a maximum layer count of up to 52L, this Flex Rigid PCB product is at the forefront of complex circuit design. Such a high layer count enables the integration of multiple circuits into a single component, significantly reducing the footprint and interconnection complexity within electronic devices. The advanced layer stack-up allows for sophisticated routing and shielding strategies that enhance signal integrity and electromagnetic compatibility, marking a significant leap in high-density interconnect (HDI) technologies.

The bend radius of the Rigid Flex PCB ranges from 0.5 to 10mm, providing an optimal balance between flexibility and mechanical strength. This flexible-bendable PCB feature is crucial for applications requiring the PCB to conform to specific shapes or to flex during use or installation. The tight bend radius enables designers to fold and shape the PCB, allowing for innovative product designs that can withstand repeated flexing. The flexibility range of 1-8 times ensures that the product can endure multiple cycles of bending without compromising its structural integrity or electrical performance, thereby extending the lifespan of the devices it powers.

Profiling and punching of the Rigid Flex Printed Wiring Board are achieved through precision techniques such as routing, V-CUT, and beveling. These manufacturing processes are carefully executed to ensure clean edges and accurate dimensions, which are vital for the assembly and fit within tight enclosures. Routing provides complex shapes and contours, while V-CUT creates straight lines and angles ideal for fold lines or detachable sections. Beveling, on the other hand, prepares the edges of connectors for smoother insertion, reducing wear and the likelihood of connection failures.

The Rigid Flex PCB is constructed using high-quality materials such as FR4, Polyimide, and PET. FR4 is a widely used flame-retardant glass-reinforced epoxy laminate that offers excellent mechanical stability and thermal resistance. Polyimide is renowned for its flexibility and high-temperature tolerance, making it perfect for dynamic flexing applications. PET, while being more cost-effective, provides a good balance of electrical properties, flexibility, and thermal endurance. The thoughtful selection of materials ensures that the PCB can operate reliably under a variety of environmental stresses including temperature fluctuations, humidity, and mechanical impacts.

In summary, the Rigid Flex PCB product is an exemplary solution that ingeniously merges the strength and stability of traditional rigid PCBs with the versatility and adaptability of flexible circuits. With up to 52 layers, a bend radius of 0.5-10mm, and a flexibility range of 1-8 times, it offers unmatched design freedom and performance. The use of premium materials such as FR4, Polyimide, and PET, combined with advanced profiling techniques like routing, V-CUT, and beveling, culminates in a PCB that is not only robust and reliable but also tailor-made for the demanding requirements of contemporary electronics. The Rigid Flex PCB product is more than just a component; it's an integral part of the future of electronic design and innovation.

Features:

- Product Name: Rigid Flex PCB

- Bend Radius: 0.5-10mm

- Sanforized: Local High Density, Back Drill

- No Of Layers: 4 Layer

- PCB Layer: 1-28 layers

- Treatment: ENIG/OSP/Immersion Gold/Tin/Silver

- Keywords:

- Flexible Stiff Circuit Board

- Foldable Rigid Circuit Board

Technical Parameters:

| Technical Parameter |

Specification |

| Product Type |

PCB Assembly |

| Treatment |

ENIG/OSP/Immersion Gold/Tin/Silver |

| Dimension |

41.55*131mm |

| Pcb Layer |

1-28 layers |

| Sanforized |

Local High Density, Back Drill |

| Max Layer |

52L |

| Surface Finishing |

HASL LF |

| Profiling Punching |

Routing, V-CUT, Beveling |

| Hole Position Deviation |

±0.05mm |

| Bend Radius |

0.5-10mm |

Applications:

The Rigid Flex PCB, or Rigid Flexible Printed Circuit Board, is an innovative solution that combines the best of both rigid boards and flexible circuits for dynamic and high-flex applications. Utilizing materials such as FR4, Polyimide, and PET, these PCBs offer a unique blend of rigidity and flexibility, capable of being bent or twisted from 1 to 8 times without compromising their integrity. This intrinsic versatility makes them ideal for a variety of product applications.

For instance, in wearable technology, the Rigid Flex PCB’s adaptability is paramount. As these devices must conform to the contours of the human body, the Bendable Rigid Printed Wiring Board can be designed to flex during use or installation. This is particularly useful in smartwatches, fitness trackers, and even advanced medical wearables, where a conformable and durable circuit solution is necessary.

In the realm of aerospace and automotive industries, the durability and high-temperature resistance of materials like Polyimide and FR4 are crucial. The Bendable Rigid Printed Wiring Board can be found in applications ranging from intricate cockpit instrumentation to under-the-hood sensors and controls. The ability to withstand the stresses of high vibrations, temperature fluctuations, and the need for compact, reliable circuitry is where the Rigid Flex PCB shines.

Moreover, the Rigid Flex PCB is a mainstay in consumer electronics where space is at a premium. Smartphones, cameras, and laptops utilize these boards to accommodate tight configurations without sacrificing performance. The precision of Profiling Punching—be it Routing, V-CUT, or Beveling—alongside the minimum trace/space capabilities of 0.1mm, ensures that high-density connections remain reliable and effective, even in the most compact devices.

The Surface Finishing of HASL LF (Hot Air Solder Leveling Lead-Free) is critical for ensuring the longevity and reliability of the board's connections, especially in environments where lead-based products are not permissible due to health or environmental regulations. This finishing process not only provides a robust solderable surface but also offers excellent shelf life, making it suitable for a wide range of applications that require stringent quality standards.

In summary, the Rigid Flex PCB product is an indispensable component in modern electronics design, offering an unmatched combination of durability, flexibility, and precision. Its versatility in design and application makes it the go-to choice for engineers and designers looking to push the boundaries of what's possible in electronic circuitry.

Customization:

Our Foldable Rigid Circuit Board offers advanced Product Customization Services to meet your most challenging design requirements. With a choice of Surface Finishing, including HASL LF, we ensure reliable solderability and a pristine finish. Tailored to your needs, our Flex Rigid PCBs offer a Flexibility range from 1-8 Times, accommodating various applications that require bending and folding.

As a premier Product Type, we specialize in PCB Assembly, providing meticulous attention to detail and ensuring high-quality results. Our services include achieving a Minimum Trace/Space of 0.1mm, which allows for high-density component placement and a compact design.

The materials we use for our Bendable Printed Circuit Boards, such as FR4, Polyimide, and PET, are selected for their durability and performance, ensuring that your product can withstand the demands of its application. Trust us to deliver a Rigid Flex PCB that surpasses your expectations in both functionality and quality.

Support and Services:

Our Rigid Flex PCB products are backed by comprehensive technical support and services to ensure your success in integrating our solutions into your applications. Our expert team is well-versed in all aspects of Rigid Flex PCB technology, including design, manufacturing, and end-use. We provide various services to assist you throughout the lifecycle of your product.

Design Support: We offer design guidelines and best practices to help you create optimized Rigid Flex PCB layouts that meet your specific needs. Our support includes stack-up recommendations, material selection, and advice on trace routing and impedance control.

Manufacturing Consultation: Our manufacturing support services are designed to help you scale from prototyping to full production. We can assist with design for manufacturability (DFM) checks, process optimization, and yield improvement strategies.

Quality Assurance: Quality is at the heart of our services. We perform rigorous testing and inspection to ensure that every Rigid Flex PCB meets the highest standards of reliability and performance.

Technical Documentation: We provide detailed technical documentation, including specifications, datasheets, and application notes, to facilitate the integration of our Rigid Flex PCBs into your products.

After-Sales Support: Our commitment to you continues beyond the sale. We are here to provide ongoing support, including troubleshooting, performance optimization, and any updates or enhancements to our products.

Our technical support and services are designed to provide you with the confidence and resources you need to succeed with our Rigid Flex PCB products. We are dedicated to your satisfaction and are ready to assist you with any questions or challenges that may arise.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!