Product Description:

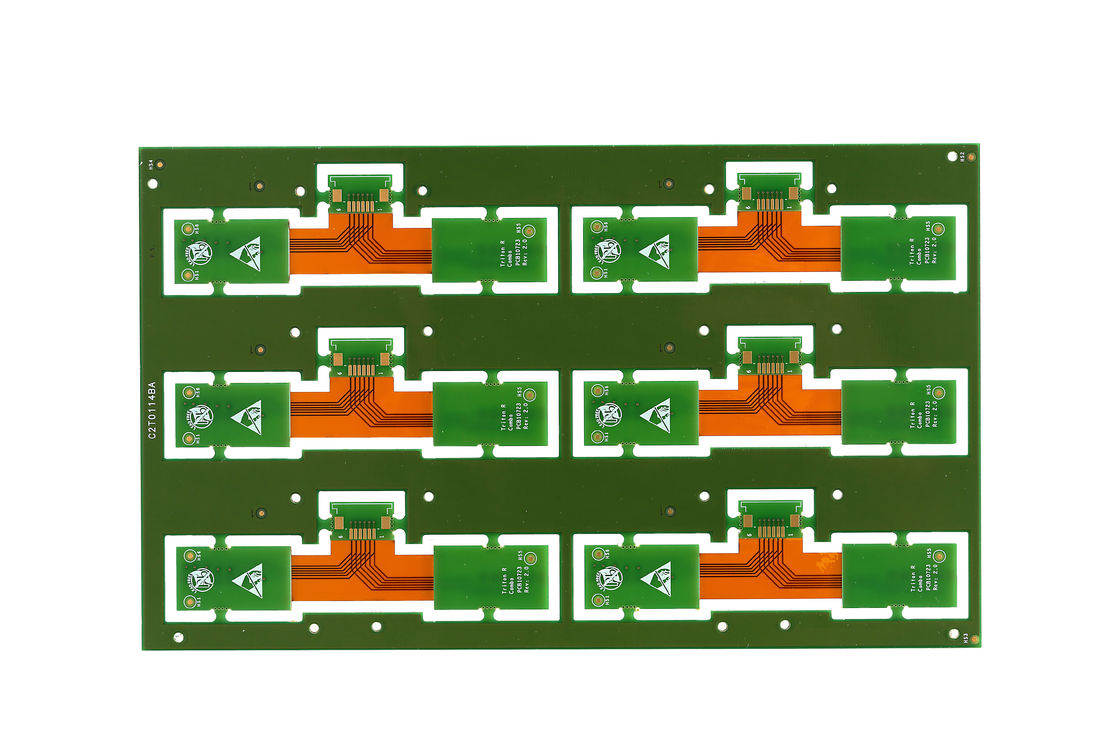

The Rigid Flex PCB, a state-of-the-art product in the realm of electronic components, is an exemplar of technological innovation, combining the rigidity of traditional PCBs with the versatility of flexible circuitry. This product is engineered to meet the sophisticated requirements of modern electronic devices that demand high-density component packaging and flexible interconnection solutions. The Rigid Flex PCB is crafted to seamlessly integrate into various applications, providing a robust yet adaptable platform for electronic assemblies.

Constructed with a Sanforized process that ensures high local density, the Rigid Flex PCB is capable of supporting a multitude of components including Surface Mount Devices (SMD), Ball Grid Arrays (BGA), Dual In-line Packages (DIP), and more. The employment of the Sanforized technique not only enhances the structural integrity of the board but also allows for the accommodation of complex circuit designs and increased component density without compromising on reliability or performance.

Additionally, the Rigid Flex PCB boasts a unique feature known as Back Drill, which is utilized to remove any residual stub in plated-through holes that could potentially affect the signal integrity, especially at higher frequencies. This precision drilling technique results in improved electrical performance and is critical for high-speed circuitry applications, ensuring that the PCB assembly delivers optimal functionality in even the most demanding environments.

The flexibility aspect of the Rigid Flex PCB is one of its most remarkable attributes. Engineered to withstand flexing of 1-8 times, this product can be folded and bent to fit into tight or unconventional spaces, making it an ideal choice for applications where space is a premium. This foldable rigid circuit board merges the best of both worlds, ensuring that the rigid sections provide the necessary mechanical support for mounted components while the flexible areas accommodate bending and folding without compromising the circuit integrity.

Quality and precision are paramount in the manufacturing of the Flex Rigid PCB. The hole position deviation is meticulously controlled within a tight tolerance of ±0.05mm. This level of precision guarantees that components are placed accurately and that the interconnectivity between the layers of the PCB is maintained, which is crucial for the overall performance of the electronic device. Such precision in the drilling process is essential for aligning the vias with the internal layers, particularly for BGA components where alignment is key for functionality.

As a product type that falls under the PCB Assembly category, the Flexible Rigid Circuit Board is designed for seamless integration with other electronic components and systems. Its versatile nature allows for a reduction in the overall system size, weight, and assembly costs by combining multiple PCBs into a single, flexible rigid solution. The elimination of connectors and cables further contributes to the reliability of the electronic assembly, as fewer connections mean fewer potential points of failure.

In conclusion, the Rigid Flex PCB is a sophisticated, innovative product that caters to the ever-evolving needs of modern electronics. Its high component density capability, enhanced by the Sanforized process, the precision of the Back Drill technique, the remarkable flexibility, and the stringent quality control measures, all converge to make this Flexible Rigid Circuit Board a superior choice for manufacturers seeking reliability, performance, and adaptability in their electronic products. With its foldable design and precision engineering, the Rigid Flex PCB stands as a testament to the advancements in the PCB industry, offering a compact, efficient, and resilient solution for today's electronic challenges.

Features:

- Product Name: Rigid Flex PCB

- PCB Layer: 1-28 layers

- No Of Layers: 4 Layer

- Material: FR4, Polyimide, PET

- Bend Radius: 0.5-10mm

- Treatment: ENIG/OSP/Immersion Gold/Tin/Silver

- Flex-Rigid Printed Circuit Board

- Rigid Flexible Printed Circuit Board

- Flexible-Bendable PCB

Technical Parameters:

| Parameter |

Details |

| Dimension |

41.55*131mm |

| Flexibility |

1-8 Times |

| Product Type |

Flex Rigid PCB Assembly |

| Pcb Layer |

1-28 layers |

| Minimum Trace/Space |

0.1mm |

| No Of Layers |

4 Layer |

| Material |

FR4, Polyimide, PET |

| Surface Finishing |

HASL LF |

| Sanforized |

Local High Density, Back Drill |

| Max Layer |

52L |

Applications:

The Rigid Flex PCB, or Flexible Rigid Circuit Board, is an innovative solution that merges the flexibility of flexible circuits with the durability and stability of rigid boards. This technology enables complex, high-density designs to be realized in a single board, making it ideal for applications where space and weight are critical factors. With a minimum trace/space of 0.1mm and sanforized for local high-density regions coupled with back drill technology, it is engineered to meet the demands of precise electrical performance and signal integrity.

Being a 4 Layer Flex-Rigid Printed Circuit Board, it is capable of accommodating a diverse range of components such as Surface Mounted Devices (SMD), Ball Grid Arrays (BGA), Dual In-line Packages (DIP), and more. This versatility allows it to be utilized in various high-tech applications, ranging from consumer electronics to medical devices and aerospace systems. The Surface Finishing of Hot Air Solder Leveling Lead-Free (HASL LF) ensures reliable solder joints and long-term durability even in harsh operating environments.

The Foldable Rigid Circuit Board is particularly well-suited for dynamic applications where the circuit needs to conform within a confined space or requires to be folded during either the assembly or deployment process. This makes it an excellent choice for portable electronics where the conservation of space is paramount, such as in smartphones, cameras, and wearable devices. Its ability to bend without compromising the integrity of the circuits allows for innovative product designs that were not previously possible.

Additionally, the Rigid Flex PCB finds its application in sectors that require robust yet flexible electronic solutions. Medical devices such as pacemakers and portable diagnostic equipment benefit from its compact form factor and reliability. In the automotive industry, the Flex-Rigid Printed Circuit Board can be found in advanced driver-assistance systems (ADAS), control units, and sensors due to its resistance to vibrations and thermal stress. The military and aerospace industries also utilize these boards for their ability to withstand extreme conditions and reduce the overall weight of the equipment.

In conclusion, the Rigid Flex PCB stands out as a versatile and durable option for various high-end applications. Its combination of fine pitch capabilities, adaptability to high-density component placement, and robust build makes it an invaluable component in the advancement of electronic product design and functionality.

Customization:

Our Rigid Flex PCB product offers extensive customization services to meet your specific design requirements. With a maximum layer count of 52L, our Flexible Rigid Circuit Board can be tailored to suit complex designs and applications. We ensure high precision with a hole position deviation of ±0.05mm, guaranteeing the accuracy needed for your sophisticated electronic components.

The PCB layering options range from 1 to 28 layers, allowing for a diverse array of configurations for your Flexible Stiff Circuit Board needs. Moreover, our Rigid Flex PCBs are designed to accommodate flexibility demands, capable of 1-8 times bending without compromising the integrity of the circuitry.

Our 4 Layer Foldable Rigid Circuit Board is a testament to our commitment to providing versatile and reliable PCB solutions. Whether for dynamic use cases or static installations, our product customization services ensure that your Rigid Flex PCB is configured to your exact specifications.

Support and Services:

Our Rigid Flex PCB products come with comprehensive technical support and services to ensure your satisfaction and the optimal performance of your PCBs. Our support includes assistance with design challenges, material selection, and layout recommendations to maximize the functionality and reliability of your Rigid Flex PCB application.

We offer detailed documentation and resources to guide you through the installation and maintenance of your Rigid Flex PCB. Our technical support team is equipped to help you with any issues related to the performance or integration of our products into your systems.

In the event of any technical difficulties, our troubleshooting services are designed to diagnose and address any problems quickly and efficiently. We are dedicated to providing you with the support you need to keep your operations running smoothly.

For continued success, we also provide updates and informational resources about advancements in Rigid Flex PCB technology and industry best practices. Our goal is to ensure that you have access to the latest information and support for your Rigid Flex PCB needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!