Product Description:

The Rigid Flex PCB, a standout solution in the realm of electronic components, is designed to cater to the most demanding applications where versatility and reliability are paramount. This cutting-edge Bendable Printed Circuit Board marries the best of both worlds, combining the robustness of traditional rigid PCBs with the adaptability of flexible circuit technology. With treatment options such as ENIG, OSP, Immersion Gold, Tin, and Silver, the product ensures optimal electrical performance and durability for a broad spectrum of uses.

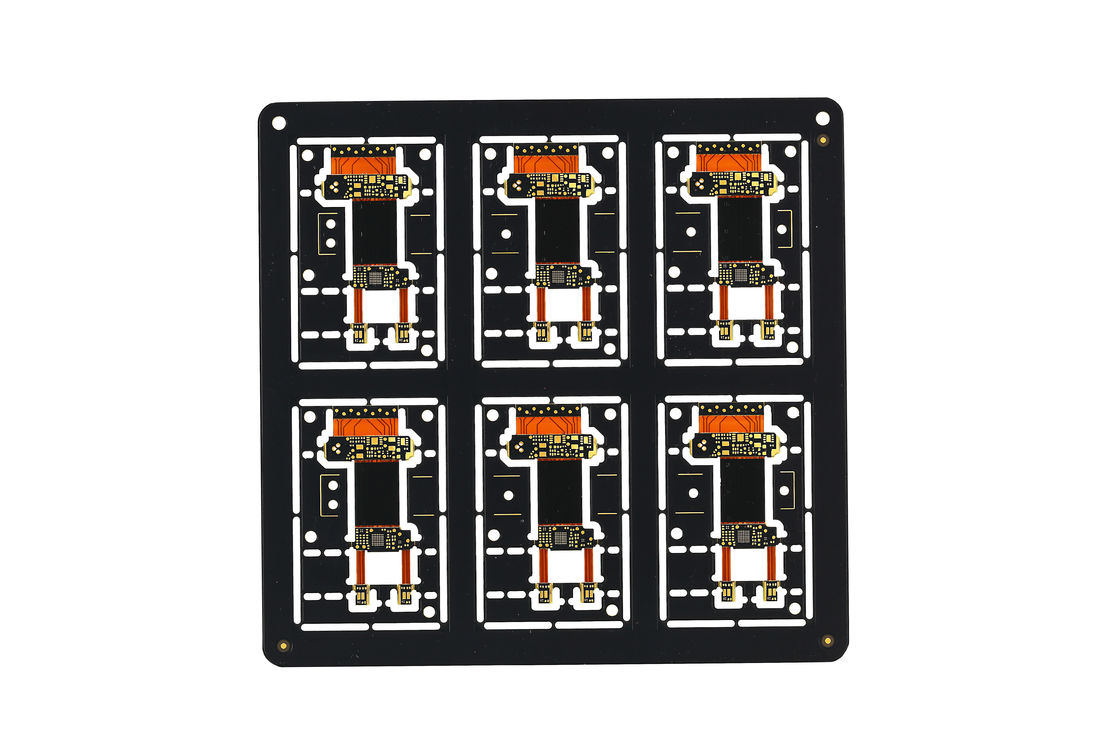

Our Rigid Flex PCB boasts an impressive configuration range, starting from a 4 Layer construction and scaling up to a remarkable 52L maximum layer count. This extensive range of layers offers a powerful testament to the product's versatility, allowing for complex and dense circuit designs that are both lightweight and compact. The craftsmanship involved in layering these boards ensures signal integrity and mechanical strength, making them a perfect fit for sophisticated electronic devices.

Flexibility is a key attribute of our Rigid Flex PCB, and it stands out by offering 1-8 times flexibility, which enables the board to be manipulated into the required shape and configuration without compromising the circuit's integrity. This feature is particularly beneficial for applications that require the PCB to fit into tight or unconventional spaces, providing engineers with the freedom to design more ergonomic and innovative products. The Foldable Rigid Circuit Board is, therefore, not just a component; it's a gateway to design flexibility and innovation.

When it comes to the PCB layer range, this product does not disappoint. With the capability to support 1-28layers, the Rigid Flex PCB is adaptable to both simple and highly complex electronic assemblies. This wide range of PCB layers facilitates the integration of multiple functions into a single unit, reducing the need for connectors and cables, which in turn minimizes the risk of connection failures and enhances the overall reliability of the electronic device.

The Rigid Flex PCB also caters to the ever-growing demand for miniaturization in electronics. The Flexible Stiff Circuit Board design allows components to be placed on both rigid and flexible areas, providing higher component density and enabling the creation of smaller, lighter devices without sacrificing performance. This is particularly advantageous in the aerospace, medical, and consumer electronics sectors, where space and weight are critical constraints.

Quality is at the forefront of our Rigid Flex PCB production. Each board is manufactured with precision, adhering to stringent quality control protocols to ensure every piece meets the high standards expected by our clients. The use of advanced materials and processes guarantees the PCBs can withstand the stresses of both assembly and operation, including bending, folding, and repetitive motions. As a result, our customers can trust that they are receiving a product that is not only flexible but also robust and long-lasting.

In conclusion, the Rigid Flex PCB is a pivotal component in modern electronics, offering a unique blend of flexibility, durability, and high performance. Whether it is for dynamic applications that require a Bendable Printed Circuit Board, systems that benefit from a Flexible Stiff Circuit Board, or devices that demand the form factor of a Foldable Rigid Circuit Board, this product delivers on all fronts. Engineered to push the boundaries of electronic design, the Rigid Flex PCB is the hallmark of innovation, designed to meet the challenges of today's and tomorrow's technological advancements.

Features:

- Product Name: Rigid Flex PCB

- Minimum Trace/Space: 0.1mm

- Surface Finishing: HASL LF

- Material: FR4, Polyimide, PET

- Sanforized: Local High Density, Back Drill

- No Of Layers: 4 Layer

- Flexible-Bendable PCB

- Bendable Printed Circuit Board

- Bendable Rigid Printed Wiring Board

Technical Parameters:

| Parameter |

Specification |

| Dimension |

41.55*131mm |

| Sanforized |

Local High Density, Back Drill |

| Hole Position Deviation |

±0.05mm |

| Profiling Punching |

Routing, V-CUT, Beveling |

| Flexibility |

1-8 Times |

| Pcb Layer |

1-28 layers |

| Bend Radius |

0.5-10mm |

| Components |

SMD, BGA, DIP, Etc. |

| Minimum Trace/Space |

0.1mm |

| Max Layer |

52L |

Applications:

The 4 Layer Flexible Rigid Circuit Board, combining the best of both rigid boards and flexible circuits, is designed for versatility and durability. This Flex-Rigid Printed Circuit Board is ideal for a wide range of applications where space is at a premium and complex connections are required. Its unique construction allows it to be bent or folded into the desired shape, with a bend radius of 0.5-10mm, ensuring that it can fit into tight spaces without sacrificing performance.

With the capacity to mount various components such as SMD, BGA, and DIP, the 4 Layer Flex-Rigid Printed Circuit Board is suitable for high-density applications. The surface finishing of HASL LF (Hot Air Solder Leveling Lead-Free) provides a reliable surface for soldering while meeting the latest environmental standards. The materials used in its construction, such as FR4, Polyimide, and PET, are known for their electrical insulation and thermal stability, making the board robust for various operating conditions.

Typical application occasions and scenarios for this Flex-Rigid Printed Circuit Board include wearable technology, where the board's flexibility allows it to conform to the contours of the human body. In the aerospace industry, the board's lightweight and space-saving design are critical for satellite and avionics systems. Medical devices also benefit from the board's compact size and flexibility, enabling it to be used in intricate diagnostic equipment and implants.

Moreover, in the automotive sector, where reliability and resistance to harsh environments are essential, the 4 Layer Flexible Rigid Circuit Board excels. It can be used in vehicle dashboard electronics, control systems, and sensors. In the field of consumer electronics, this board can be found in smartphones, tablets, and other portable devices, where the blend of rigidity and flexibility offers unmatched design freedom.

In conclusion, the versatile 4 Layer Flex-Rigid Printed Circuit Board bridges the gap between traditional rigid PCBs and flexible circuits, offering a multifaceted solution for electronic products that demand compactness, reliability, and intricate circuitry. Its construction and material composition provide a robust platform for a variety of components, making it an essential piece of technology for cutting-edge electronic applications.

Customization:

Our Foldable Rigid Circuit Board offers a range of customization services to meet the exacting needs of your project. With flexibility options ranging from 1-8 times, we ensure that your Rigid Flex PCB can withstand the dynamic stresses of your application.

To enhance the performance of our Flexible Rigid Circuit Board, we offer Local High Density and Back Drill Sanforized options, ensuring your PCB is precise and reliable for high-speed and high-frequency applications.

Our Rigid Flexible Printed Circuit Board can be designed with up to 52L Max Layer, providing ample space for complex circuit designs and multi-layer configurations, ensuring optimal electrical performance and space utilization.

We understand the importance of precision in PCB design, which is why we offer a Minimum Trace/Space of 0.1mm, allowing for high-density component placement and a reduction in signal cross-talk and interference.

Additionally, our Profiling Punching services, which include Routing, V-CUT, and Beveling, are available to give your Rigid Flex PCB the exact shape and finish required for seamless integration into your final product.

Support and Services:

Our Rigid Flex PCB products come with comprehensive technical support and services designed to ensure the highest level of performance and reliability. Our team of experienced engineers is dedicated to providing expert advice and assistance throughout the product lifecycle, from design and prototyping to post-production and troubleshooting.

Technical Support Services Include:

- Design Consultation: Our experts are available to consult on the design and layout of your Rigid Flex PCB, helping to optimize functionality and manufacturability.

- Material Selection: We provide guidance on choosing the right materials for your specific application to ensure durability and performance.

- Prototyping Services: Benefit from rapid prototyping capabilities to test and refine your Rigid Flex PCB designs before full-scale production.

- Manufacturing Support: Receive assistance with manufacturing processes to ensure your PCBs are produced to the highest quality standards.

- Assembly and Integration: Get support for the assembly and integration of your Rigid Flex PCBs into final products, ensuring proper fit and function.

- Troubleshooting: Our technical support team is ready to help diagnose and resolve any issues that may arise with your Rigid Flex PCBs.

- Technical Documentation: Access detailed documentation covering specifications, handling instructions, and best practices for your Rigid Flex PCBs.

- Training: We offer training sessions for your team to ensure they are up to date on the latest Rigid Flex PCB technologies and techniques.

We are committed to providing our customers with the support they need to succeed. Our goal is to ensure that our Rigid Flex PCB products meet your requirements and exceed your expectations.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!