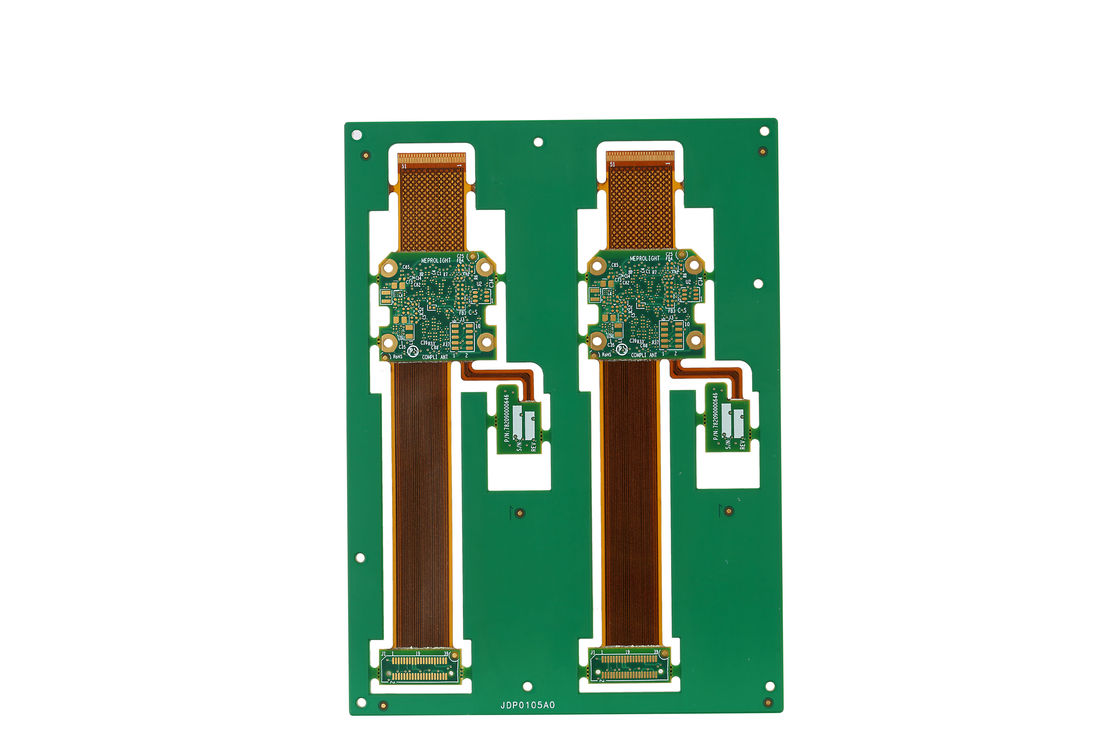

4 Layer Smd Components Flex Rigid Pcb Flexible Bendable Pcb Assembly Hasl Lf Surface Finish

Product Description:

The Rigid Flex Printed Circuit Board (PCB) is an innovative and cutting-edge solution designed for a wide range of electronic applications. This product ingeniously combines the flexibility of flexible PCBs with the durability and stability of rigid PCBs, creating a board that can be flexed or bent to meet the needs of complex electronic assemblies. Our Rigid Flex PCBs offer unparalleled versatility and reliability, ensuring they are well-suited for industries that require precision and durability.

One of the standout features of our Rigid Flex PCB is its surface finishing. The board is treated with Hot Air Solder Leveling Lead-Free (HASL LF), which is an eco-friendly alternative to traditional HASL. This type of finishing provides excellent surface planarity for component mounting and is highly reliable in terms of solderability. It ensures that even after multiple reflows, the PCB maintains its integrity and electrical connectivity remains consistent.

In the realm of miniaturization and high-density applications, the minimum trace/space specification of our Rigid Flex PCB is essential. With a minimum trace and space width of 0.1mm, our boards support intricate designs and can accommodate more circuits per unit area. This precision allows for the development of highly complex and compact electronic devices without sacrificing performance or quality.

The flexibility aspect of our Rigid Flex PCBs is not just a feature but a significant advantage. With the ability to bend and flex between 1 to 8 times, these boards provide designers with the freedom to innovate without the constraints of traditional rigid boards. This flexibility is crucial for applications that require the PCB to conform to specific shapes or to fit into tight or unusually shaped spaces. Whether it is for wearable technology, medical devices, or aerospace instrumentation, our Flexible-Bendable PCBs ensure that your products can adapt to any form factor while maintaining a high level of performance.

Precision is a cornerstone of our Rigid Flex PCB manufacturing process. The hole position deviation is maintained within a stringent tolerance of ±0.05mm. This level of accuracy is crucial for the correct alignment of multi-layer boards and ensures that the vias and through-holes are perfectly positioned, resulting in consistent electrical connections and functionality across the entire batch of PCBs produced.

To support local high-density interconnect (HDI) designs, our Rigid Flex PCBs employ a sanforization process. This involves the use of specific techniques such as back drilling to remove any unused portions of plated through-holes, effectively reducing signal noise and improving signal integrity in high-speed circuits. This is particularly beneficial for applications that demand the utmost in electrical performance and reliability.

In summary, our Rigid Flex Printed Circuit Board is a superior product that embodies the latest in PCB technology. It is a Flexible-Bendable PCB designed to meet the rigorous demands of modern electronic devices. With features such as HASL LF surface finishing, a minimum trace/space of 0.1mm, the ability to flex up to 8 times, precise hole position deviation, and local high-density sanforization with back drill, this Flex-Rigid Printed Circuit Board stands out as a premium choice for any application where quality, performance, and flexibility are paramount.

Choose our Rigid Flex PCB for your next project and experience the perfect blend of flexibility, precision, and performance. Whether for consumer electronics, medical devices, automotive applications, or aerospace technology, our boards are designed to deliver exceptional results and drive innovation in your products.

Features:

- Product Name: Rigid Flex PCB

- Profiling Punching: Routing, V-CUT, Beveling

- Bend Radius: 0.5-10mm

- Sanforized: Local High Density, Back Drill

- Pcb Layer: 1-28 layers

- Surface Finishing: HASL LF

- Also known as Rigid Flex Printed Wiring Board

- Technology includes Flex Rigid PCB designs

- Flexible Rigid Circuit Board construction for versatile applications

Technical Parameters:

| Attribute |

Specification |

| No Of Layers |

4 Layer |

| Material |

FR4, Polyimide, PET |

| Pcb Layer |

1-28 layers |

| Sanforized |

Local High Density, Back Drill |

| Minimum Trace/Space |

0.1mm |

| Product Type |

PCB Assembly |

| Hole Position Deviation |

±0.05mm |

| Treatment |

ENIG/OSP/Immersion Gold/Tin/Silver |

| Bend Radius |

0.5-10mm |

| Flexibility |

1-8 Times |

Applications:

The Rigid Flex PCB, combining the best of both rigid boards and flexible circuits, is an innovative solution tailored for complex applications where precision and durability are paramount. This 4-layer product integrates various components such as Surface-Mount Devices (SMD), Ball Grid Arrays (BGA), and Dual In-line Packages (DIP) on a robust platform composed of high-quality materials like FR4, Polyimide, and PET. The Rigid Flex PCB allows for seamless integration into dynamic electronic environments, offering exceptional versatility.

With its Flexible-Bendable PCB attribute, this product is a perfect match for occasions where the circuit needs to conform to a particular shape or fit into unconventional spaces. The bendable sections can be manipulated to accommodate tight corners and complex contours, making it ideal for advanced wearable technology, medical devices, and compact consumer electronics where spatial efficiency is crucial. Its foldability adds an extra dimension of mechanical flexibility, ensuring that the Foldable Rigid Circuit Board can endure repeated flexing without compromising performance or reliability.

The profiling punching techniques, such as Routing, V-CUT, and Beveling, provide precise edge finishing and allow for easy separation of multiple PCBs from their manufacturing panels. This precision is essential in scenarios where the Rigid Flex PCB is part of a larger assembly process requiring accurate alignment and fit. These profiling methods ensure that the board can be integrated with other components with ease and reliability.

The surface treatment options such as ENIG, OSP, Immersion Gold, Tin, and Silver, cater to various application scenarios. For instance, ENIG offers excellent surface planarity for BGAs, making it suitable for high-density applications in telecommunications and aerospace industries. In contrast, Immersion Silver might be the preferred choice for applications requiring outstanding conductivity, like in high-frequency devices. These treatments not only provide the necessary protection against oxidation but also ensure reliable solderability for a wide range of components.

Overall, the Rigid Flex PCB stands out for its adaptability and reliability across numerous applications. Whether it's in a folding smartphone, a smartwatch, or a sophisticated satellite, the Flexible-Bendable PCB design of this 4-layer board ensures that it can meet the rigorous demands of modern electronics, combining mechanical flexibility with the robustness of a traditional rigid PCB.

Customization:

Our custom Rigid Flex PCBs offer a dynamic solution perfect for advanced electronic applications. This Bendable Printed Circuit Board combines the best of both worlds: the flexibility of a Flexible Stiff Circuit Board with the durability of a rigid PCB. Our Flex Rigid PCB product customization services include a variety of components such as SMD, BGA, DIP, and more to meet your specific design requirements.

We are committed to precision in our products, offering a Minimum Trace/Space of 0.1mm. Our advanced technology ensures that even the most complex designs are executed with the highest level of accuracy.

Our Rigid Flex PCBs come with various surface treatment options, including ENIG, OSP, Immersion Gold, Immersion Tin, and Immersion Silver, to ensure optimal performance and longevity of your PCB.

With the capability to produce from 1 to 28 layers, our PCBs are designed to be versatile for use in a wide range of applications. The materials we offer, such as FR4, Polyimide, and PET, are selected for their quality and reliability, ensuring that your Bendable Printed Circuit Board is built to last.

Support and Services:

The Rigid Flex PCB (Printed Circuit Board) combines the technology of rigid PCBs and flexible PCBs to create a durable and versatile circuit solution. Our Product Technical Support and Services are dedicated to ensuring that our customers can design, implement, and maintain their Rigid Flex PCBs with ease and confidence. Our support includes comprehensive design guidelines for optimal flexibility and rigidity, material selection advice to meet your specific needs, and thermal management solutions for high-reliability applications. Additionally, we provide troubleshooting assistance, best practices for PCB care and maintenance, and guidance on meeting industry standards and certifications. Our team is committed to providing you with the highest level of service to help you get the most out of your Rigid Flex PCB product.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!