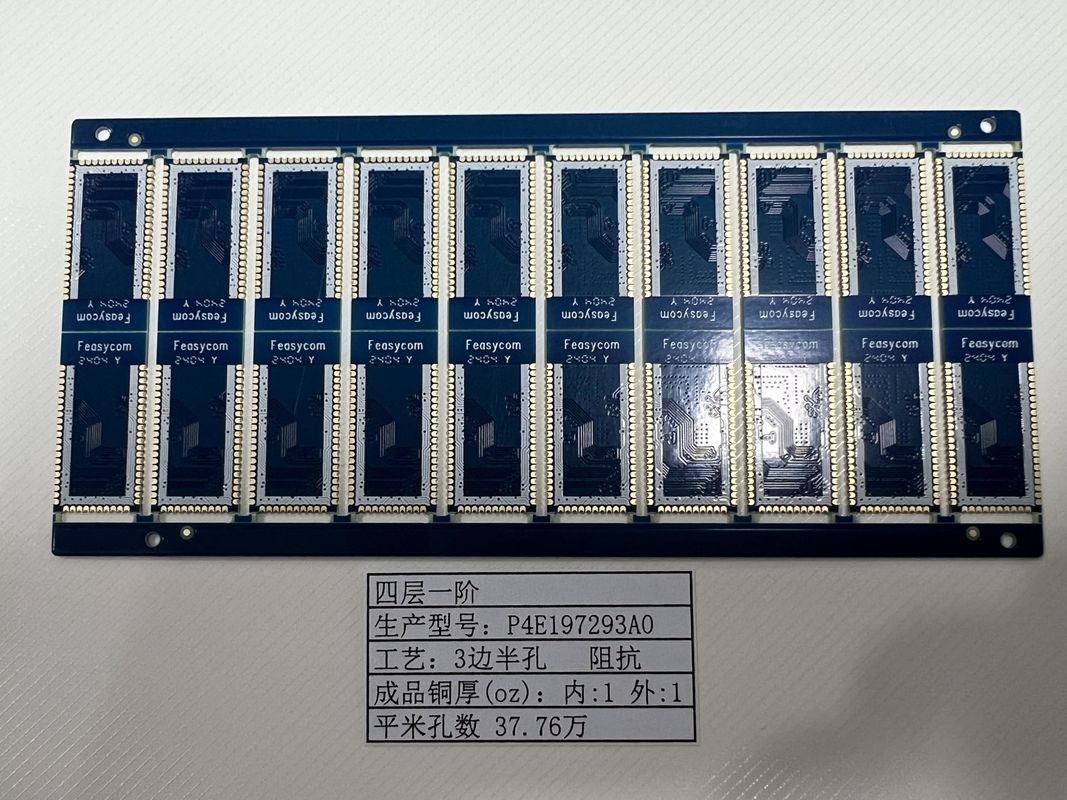

4L High Density Pcb / Hdi Pcb Board With Impedance Control Half Hole Bga Density Interconnector

Product Description:

The HDI PCB Board represents the pinnacle of modern printed circuit board (PCB) technology, catering to the increasing demand for compact, high-speed, and efficient electronic components. HDI, which stands for High Density Interconnect, is a technology that enables more functionality in a smaller space, a crucial factor in the development of the latest consumer electronics, medical devices, and communication tools. This product is specifically designed to integrate seamlessly with HD SDI Converters, complement high-speed PCB applications, and support the latest memory modules, such as DDR4 PCBs.

Featuring an impressive hole size of 0.1mm achieved through precision laser drilling, the HDI PCB Board allows for a level of detail and a density of components not possible with traditional drilling methods. This fine hole size is particularly beneficial for applications requiring a high number of interconnections within a confined space, such as HD SDI Converters, which are used to transmit high-definition video signals over long distances without loss of quality.

In terms of trace resolution, the HDI PCB Board boasts a minimum trace width and spacing of 3/3Mil (0.003 inches), a specification that underscores the board's suitability for High Speed PCB applications. This fine trace geometry is instrumental in reducing signal loss and cross-talk, thereby ensuring signal integrity at high frequencies. This level of precision is essential for the performance of DDR4 PCBs, which operate at high data rates and require a meticulously designed layout to maintain signal integrity.

The board thickness of the HDI PCB Board can be customized within a wide range from 0.2mm to 6.00mm (8mil to 126mil). This versatility allows the board to be tailored to the requirements of various applications, from the slimmest portable devices to more robust industrial equipment. A thinner board can be beneficial for portable electronics, while a thicker board might be chosen for its enhanced structural integrity in demanding environments.

The minimum hole size of 0.15mm is yet another feature that highlights the high-resolution capabilities of the HDI PCB Board. This attribute allows for the placement of smaller vias, which are critical in the design of multilayer PCBs. These small vias enable multiple layers to be interconnected, maximizing space and improving performance, which is particularly useful in the realm of HD SDI Converters, where precision and reliability are paramount.

Impedance control is an essential feature of the HDI PCB Board, guaranteeing that the PCB maintains a consistent impedance throughout the circuit. This is of paramount importance in High Speed PCB applications, where variations in impedance can lead to signal reflections and loss of signal integrity. The ability to control impedance is also crucial for DDR4 PCBs, as these memory modules require a consistent impedance to operate at peak efficiency and stability.

In summary, the HDI PCB Board is an advanced solution engineered for high-performance electronics. Its compatibility with HD SDI Converters, suitability for High Speed PCB applications, and optimized design for DDR4 PCBs make it an ideal choice for projects demanding the highest standards in precision, reliability, and efficiency. With features like the 0.1mm laser-drilled hole size, 3/3Mil minimum trace, customizable board thickness, minimum hole size of 0.15mm, and impedance control, the HDI PCB Board stands at the forefront of PCB technology, ready to meet the needs of the most challenging electronic designs.

Features:

- Product Name: HDI PCB Board

- Testing:

- Special Request:

- Special Requirements: Lamp Socket

- Impedance Control: Yes

- Minimum Hole Size: 0.15mm

- Compatible with HD SDI Converter applications

- High-density interconnect technology for HDI PCB

Technical Parameters:

| Technical Parameter |

Specification |

| Special Requirements |

Lamp Socket |

| Key Words |

High Density Interconnector |

| Testing |

100% E-Testing, X-RAY |

| Aspect Ratio |

10:1 |

| Thickness |

0.4-3.2mm |

| Min Trace |

3/3Mil |

| Hole Size |

0.1mm Laser Drill |

| Impedance Control |

Yes |

| Special Request |

Half Hole, 0.25mm BGA |

| Minimum Hole Size |

0.15mm |

Applications:

HDI PCBs, or High Density Interconnector Printed Circuit Boards, represent a significant advancement in PCB technology. By utilizing the finest materials such as FR4 IT180, HDI PCBs like the 4L 1+N+1 HDI Boards are designed to meet the rigorous demands of modern electronics. The 4L denotes a four-layer PCB, while the 1+N+1 indicates the build-up of one layer, followed by an internal layer (N), and capped by another layer, showcasing the intricate design enabled by HDI PCB manufacturing processes.

One of the critical attributes of these HDI PCBs is their board thickness, which ranges from a slender 0.2mm to a robust 6.00mm (8mil to 126mil). This versatility ensures that HDI PCBs can be integrated into a vast array of applications, from the most delicate wearables to more substantial, high-power electronics. Moreover, the assurance of impedance control guarantees signal integrity across various frequencies, a non-negotiable in high-speed designs.

The application occasions and scenarios for HDI PCBs are diverse, spanning multiple industries and technologies. In the realm of consumer electronics, HDI Printed Circuit Boards are the backbone of smartphones, tablets, and laptops, where space is at a premium, and efficiency is paramount. The miniaturization of components coupled with the high-speed requirements makes HDI PCBs an essential choice for manufacturers aiming to produce sleek, yet powerful devices.

In the telecommunications sector, HDI PCBs enable the functionality of complex, multi-layer routers and switches that form the core of our internet infrastructure. The ability to support a multitude of connections within a confined space, while maintaining signal integrity, is why HDI PCBs are a staple in this industry. Similarly, in the field of medical electronics, the precision and reliability offered by HDI PCBs are leveraged in critical devices such as pacemakers and imaging systems, where consistent performance could mean the difference between life and death.

Automotive and aerospace industries, where extreme conditions and the need for reliability and miniaturization converge, also benefit from the attributes of HDI PCBs. High-density interconnects provide the necessary resilience and enable the complex electronic systems used in modern vehicles and aircraft. Additionally, military and defense applications, where ruggedness and advanced technological capabilities are necessary, frequently employ HDI PCBs to ensure the functionality and durability of their electronic systems.

In each of these applications, the HDI PCB stands out as a critical component due to its ability to facilitate advanced electronic architectures while maintaining a compact footprint. Whether it's in the high-stakes environment of aerospace, the precision-dependent world of medical technology, or the consumer electronics that we use daily, HDI PCBs are the unsung heroes enabling the technological leaps of our time.

Customization:

Our High Density PCB customization services cater to your specific needs, ensuring that your HDI Printed Circuit Boards meet the highest quality standards. With options for a Special Request, we can incorporate Half Hole technology and accommodate a 0.25mm BGA for precise component placement. The Raw Material used is the reliable FR4 IT180, guaranteeing excellent thermal endurance and mechanical strength for your High Speed PCB applications.

We also offer Impedance Control to maintain signal integrity across your HDI PCB Board, essential for high-speed circuitry. Our capabilities include maintaining a Min Trace of 3/3Mil, providing you with the fine line precision required for complex circuit designs. Furthermore, our product customization allows for a Board Layer configuration of up to 6L, enabling us to support your multi-layered High Density PCB requirements.

Support and Services:

The HDI PCB Board product comes with comprehensive technical support and services to ensure your satisfaction and success with our product. Our support includes a complete range of services from product troubleshooting, performance optimization, to guidance on best practices for design and implementation.

Our technical support team is well-versed in all aspects of HDI PCB technology and can provide assistance with stack-up recommendations, material selection, and understanding of the manufacturing constraints. They are equipped to help you resolve any issues you may encounter during the design, testing, or assembly processes.

In addition to troubleshooting, we also offer advanced services like signal integrity analysis and thermal management advice to ensure your HDI PCB operates efficiently and reliably under all conditions. Our goal is to help you maximize the performance and longevity of your product.

We are continuously improving our support resources, including detailed documentation, FAQs, and technical guides, which are available to help you navigate through common challenges and inquiries related to HDI PCBs.

Please note that our technical support and services are available during regular business hours and are subject to our service terms and conditions. We are committed to providing you with the support you need for a seamless experience with our HDI PCB Board product.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!