Product Description:

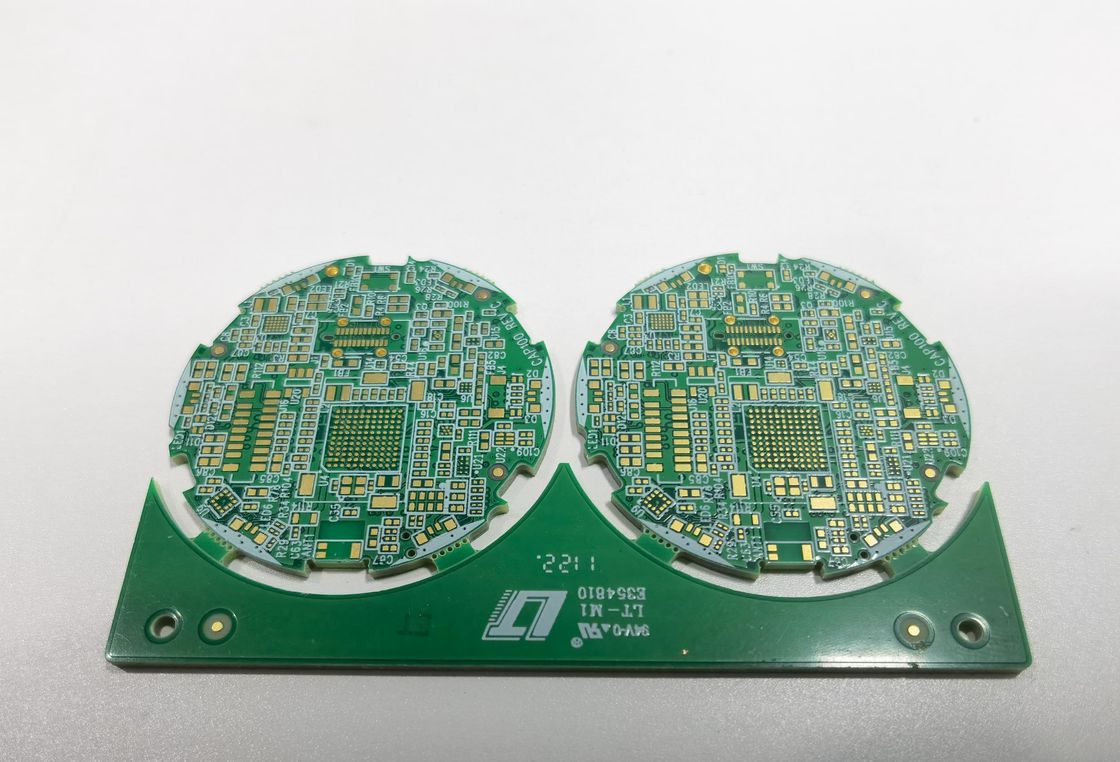

The High-Density Interconnect (HDI) PCB Board is a pinnacle of modern printed circuit board (PCB) technology that caters to the ever-increasing demand for more compact, high-performance electronic devices. HDI PCBs are sought after for their ability to support advanced features in smaller form factors, making them ideal for a plethora of high-speed and high-frequency applications, including the pivotal role they play in HD SDI Converters. With the integration of fine features and enhanced electrical performance, HDI PCBs are undoubtedly the backbone of High Speed PCB design and manufacturing.

One of the standout features of this HDI PCB Board is the incredibly small hole size that it can accommodate. Thanks to the cutting-edge 0.1mm Laser Drill technology, this board allows for precise and minute vias, which are essential for multi-layer connections in complex PCBs. The minimum hole size specification for this product is 0.15mm, which is significantly smaller than the conventional PCBs, allowing for a higher density of connections and a more compact overall board design. This feature is crucial for applications such as HD SDI Converters that require a dense concentration of connections for high-definition signal transmission.

In addition to the impressive hole size capabilities, this HDI PCB Board boasts a Min Trace of 3/3Mil. This specification refers to the minimum width and spacing of conductive tracks, or traces, which can be achieved on the board. The ability to have such narrow traces is vital for creating high-density circuits necessary for High Speed PCB applications, where space is at a premium and signal integrity is paramount. This level of precision supports the integration of more circuits in a given area, thereby enabling sophisticated electronic functions within a smaller footprint.

Impedance control is another critical attribute of the HDI PCB Board, ensuring that the board meets the exact electrical performance requirements necessary for reliable operation. Impedance control is an essential aspect of high-speed circuit design, as it helps to maintain signal integrity, reduce signal reflection and crosstalk, and ensure the consistent performance of the PCB. This is particularly important in the context of HD SDI Converters, where the fidelity of high-definition video signals is crucial. The HDI PCB Board's impedance control feature guarantees that the device will perform to the highest standards, even under rigorous conditions.

For specialized applications, this HDI PCB Board can accommodate unique requirements, such as Half Hole and 0.25mm Ball Grid Array (BGA) configurations. The Half Hole feature enables edge plating on the holes, which is used for creating a connection between the board edge and the components. This capability is particularly useful for connectors that require a robust physical and electrical connection to the board. The 0.25mm BGA pitch capability reflects the board's compatibility with extremely fine-pitch components, which are becoming more prevalent as devices continue to shrink in size while increasing in functionality. The precision with which this HDI PCB Board can handle such specialized requests makes it an ideal choice for cutting-edge electronic applications that demand the highest levels of accuracy and performance.

Overall, the HDI PCB Board is a technologically advanced solution tailored for applications that require high-density, high-precision, and High Speed PCB characteristics. Its fine features, including the 0.1mm Laser Drill hole size, 3/3Mil Min Trace, and stringent impedance control, combined with capabilities to meet special requests like Half Hole and 0.25mm BGA, make this product an excellent choice for sophisticated electronic systems, particularly those used in HD SDI Converter technologies. With this HDI PCB Board, designers and engineers are equipped to push the boundaries of what's possible in electronic device miniaturization while maintaining exceptional performance and reliability.

Features:

- Product Name: HDI PCB Board

- High Density PCB: Yes, specifically designed for advanced electronic applications

- HDI Printed Circuit Boards: Incorporating the latest technologies in HDI fabrication

- Special Requirements: Lamp Socket integration capability

- Impedance Control: Yes, ensuring signal integrity for high-speed designs

- Layer Count: Versatile range from 4-20 Layers to accommodate various design complexities

- High Density Model Board: Engineered for high-density component placement

- Special Request: Half Hole technology, and 0.25mm BGA for fine pitch components

- Testing: 100% E-Testing and X-RAY inspection to guarantee product reliability

Technical Parameters:

| Attribute |

Details |

| Board Layer |

6L |

| Pcb Name |

4L 1+N+1 HDI Boards |

| Special Requirements |

Lamp Socket |

| Hole Size |

0.1mm Laser Drill |

| Aspect Ratio |

10:1 |

| Special Request |

Half Hole, 0.25mm BGA |

| Key Words |

High Density Interconnector |

| Board Thickness |

0.2mm-6.00 mm (8mil-126mil) |

| Minimum Hole Size |

0.15mm |

| Testing |

100% E-Testing, X-RAY |

Applications:

The High Density Interconnect (HDI) Printed Circuit Board (PCB), crafted with premium FR4 IT180 raw material, is an exceptional choice for a myriad of applications that require a High Density PCB with advanced features such as Half Hole and 0.25mm Ball Grid Array (BGA). Our HDI PCB Board, which ranges from 4 to 20 layers, can confidently support a variety of high-speed and high complexity circuits due to its impressive aspect ratio of 10:1 and a board thickness that spans from 0.2mm to 6.00mm (8mil-126mil). This makes the HDI PCB Board an ideal substrate for High Density Model Boards and High-Speed PCB applications.

Applications for the HDI PCB Board are diverse and extend across various high-tech industries. In the realm of consumer electronics, these boards are commonly found in smartphones, tablets, and laptops where space is at a premium, and the demand for faster signal transmission is paramount. HDI technology allows for more functions per unit area, which makes the High Density PCB Board suitable for compact devices that require a high number of connectors and switches.

In the telecommunications sector, HDI PCB Boards are integral to the infrastructure that enables high-speed data transfer. Network routers, switches, and signal relay systems benefit significantly from the use of High Density Model Boards, ensuring that communication devices perform reliably and at the necessary speeds demanded by modern technology.

The medical industry also relies on HDI PCB Boards for their high-speed and high-density capabilities. Medical imaging equipment, such as CT scanners and MRI machines, require precise and reliable High Density PCBs to produce accurate diagnostic results. Similarly, portable medical devices benefit from the miniaturization that HDI PCBs offer, allowing for more portable and user-friendly designs.

In the automotive sector, where the integration of electronic systems continues to advance, HDI PCB Boards are used in safety-critical systems, such as airbag controllers and ABS systems. The robustness of FR4 IT180 material, coupled with the board's ability to support high aspect ratios, makes it suitable for the harsh environments and the reliability required for automotive applications.

Aerospace and defense applications also utilize HDI PCB Boards for their high-speed signal transmission and high-density packaging. The need for lightweight, compact, and highly reliable circuitry in spacecraft, satellites, and defense equipment makes the High Density Model Board an indispensable component in this sector.

Overall, the HDI PCB Board product is versatile, accommodating a wide range of applications where high density and high speed are critical to the product's performance and reliability. Its adaptability to special requests and varying layer counts ensures that it can meet the specific needs of the most demanding electronic designs and applications.

Customization:

Our High Density Interconnect (HDI) Printed Circuit Boards are tailored to meet your precise specifications, ensuring that your HDI PCB performs to the highest standards. For those in need of advanced features, we offer Product Customization Services for the HDI PCB Board product to include the following attributes:

Special Request: We can incorporate Half Hole technology, which is essential for certain types of surface mount components, and we can accommodate a minimum BGA size of 0.25mm, ensuring that your High Density Model Board can meet the needs of even the most component-dense designs.

Layer Count: Our customization service offers a versatile range of layer counts, from 4 up to 20 layers, allowing for complex routing and increased functionality in your HDI PCB design.

Special Requirements: For applications that require unique fittings such as Lamp Sockets, we have the capability to customize your HDI PCB to include these specific requirements, ensuring compatibility and reliability.

Raw Material: We utilize high-quality FR4 IT180 raw material for our HDI PCBs, providing excellent thermal endurance and mechanical strength to your circuit board.

Impedance Control: Impedance control is a critical aspect of HDI PCBs, and we guarantee precise impedance matching to ensure signal integrity and optimal performance of your HDI Printed Circuit Boards.

Support and Services:

Our HDI PCB Board comes with comprehensive technical support and services to ensure your satisfaction and the optimal performance of your product. Our support includes a detailed product manual with instructions for installation, operation, and troubleshooting. Additionally, we offer online resources such as FAQs, technical articles, and video tutorials to guide you through common issues and maintenance procedures.

For complex or unresolved issues, our dedicated team of experienced technicians is available to provide you with personalized support. They are well-versed in all aspects of HDI PCB technology and can assist with circuit design optimization, signal integrity analysis, and thermal management strategies. Our goal is to provide you with the knowledge and assistance you need to maximize the longevity and reliability of your HDI PCB Board.

We are committed to continuous improvement and customer feedback is invaluable to us. Our services include regular updates to our product documentation and support materials based on the evolving needs of our users. Additionally, we offer service packages for extended warranty, expedited repair services, and on-site technical support for critical or time-sensitive applications.

Please note that our support and services are designed to complement your technical expertise and are subject to our terms of service. We encourage you to familiarize yourself with these terms to ensure a seamless support experience. Our commitment to excellence is unwavering, and we look forward to assisting you with all your HDI PCB Board needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!