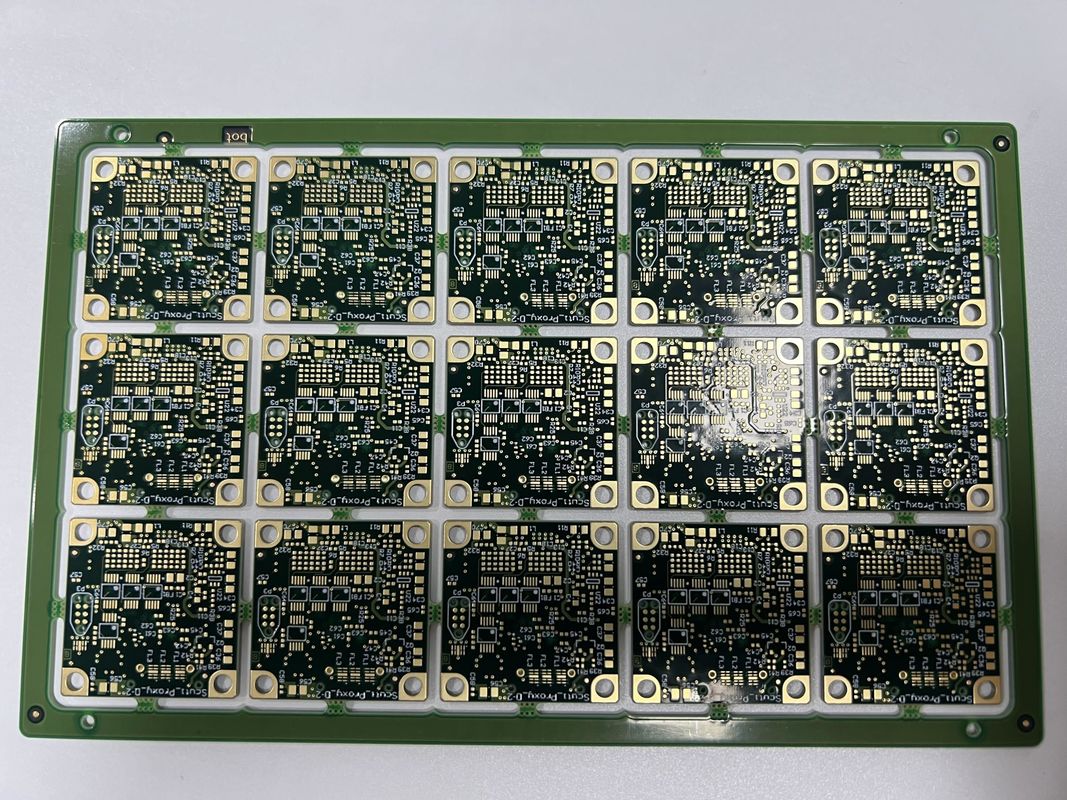

6 Layer 4-20 Layer Count High Speed Pcb Board With Lamp Socket 0.4-3.2Mm Impedance Control

Product Description:

The world of electronics is ever-evolving, demanding more sophisticated and compact solutions that can handle increasingly complex tasks. High Density Interconnect (HDI) Printed Circuit Boards (PCBs) are at the forefront of this technological revolution, enabling the creation of high-performance devices with reduced size and weight. This product summary will delve into the specifics of an HDI PCB Board that is designed to meet the rigorous requirements of advanced electronic applications.

At the core of the HDI PCB Board's capabilities is its incredibly fine hole size. The board features a 0.1mm Laser Drill, which allows for the creation of micro vias. These minuscule holes are essential for the miniaturization of electronic components, providing pathways for interconnections between the multiple layers of the PCB. This precision drilling ensures that the board can host a densely packed arrangement of components, essential for devices such as an HD SDI Converter that requires compact yet powerful circuitry.

Quality and reliability are paramount in the world of HDI PCBs, and this product does not disappoint. It undergoes 100% E-Testing to ensure that every electrical connection is sound and that the board functions as intended right out of the gate. In addition, X-RAY testing is employed to verify the internal structures and to ensure the integrity of the micro vias and other critical features. These rigorous testing standards guarantee that each HDI PCB Board meets the highest quality benchmarks before it is deployed in applications such as HD SDI Converters.

The versatility of this HDI PCB Board is reflected in its range of board thicknesses. The product is available in thicknesses from 0.2mm to 6.00mm (8mil to 126mil), accommodating a wide array of design requirements and applications. Whether you are designing a slim, handheld device or a robust, high-power piece of equipment, this range ensures that there is a board thickness to match your specifications. The board's aspect ratio of 10:1 further emphasizes its high-density interconnect capabilities, allowing for more complex and intricate designs.

In response to special design requests and to cater to the needs of advanced electronic assemblies, the HDI PCB Board offers the option of half-hole technology, which is particularly useful for edge connector requirements and improving the board's connectivity with peripheral components. Additionally, it is designed to support a 0.25mm Ball Grid Array (BGA) pitch. This fine-pitch BGA capability is crucial for achieving a high level of miniaturization, necessary for high-density applications such as HD SDI Converters that demand a large number of interconnects in a small area.

The HDI PCB Board is a testament to the capabilities of modern circuit board technology, pushing the boundaries of what is possible within the realms of high-density applications. Its precise 0.1mm Laser Drill, comprehensive testing protocols, variable board thickness, and aspect ratio, along with special features like half-hole technology and fine-pitch BGA support, make it an ideal candidate for anyone looking to integrate high-performance circuitry into their electronic designs. Whether you're crafting the next generation of HD SDI Converters or any other high-density PCB application, this HDI PCB Board provides the foundation for reliability, performance, and miniaturization in your projects.

Features:

- Product Name: HDI PCB Board

- Min Trace: 3/3Mil

- Testing: 100%E-Testing, X-RAY

- Aspect Ratio: 10:1

- Hole Size: 0.1mm Laser Drill

- Minimum Hole Size: 0.15mm

- HDI PCB Manufacturing

- High Speed PCB

- DDR4 PCB

Technical Parameters:

| Technical Parameter |

Specification |

| Board Layer |

6L |

| Thickness |

0.4-3.2mm |

| Key Words |

High Density Interconnector |

| Layer Count |

4-20 Layers |

| Aspect Ratio |

10:1 |

| Board Thickness |

0.2mm-6.00mm (8mil-126mil) |

| Min Trace |

3/3Mil |

| Special Requirements |

Lamp Socket |

| Special Request |

Half Hole, 0.25mm BGA |

| Testing |

100% E-Testing, X-RAY |

Applications:

The 4L 1+N+1 HDI Boards are a class of high-density interconnect (HDI) PCBs that are essential for modern electronics where performance, space, and reliability are critical. These boards are particularly suited for high-speed PCB applications, owing to their fine features and advanced manufacturing techniques. With a minimum hole size of 0.15mm, these HDI PCBs can accommodate a high number of interconnects in a compact space, making them ideal for high-speed signal transmission.

One of the key application scenarios for the 4L 1+N+1 HDI Boards is in the realm of HDI PCB manufacturing for consumer electronics. Devices such as smartphones, tablets, and laptops demand thin, lightweight, and high-performance circuit boards. The board thickness ranging from 0.2mm to 6.00mm (8mil-126mil) allows for multiple layers of circuits to be packed tightly together, resulting in faster signal transmission and reduced cross-talk, which is pivotal for the functionality of these high-speed devices.

In the field of professional video production, the need for reliable and high-quality signal conversion is paramount. HDI PCBs like the 4L 1+N+1 are integral in the design and function of high-definition serial digital interface (HD SDI) converters. These converters rely on the precision and high aspect ratio (10:1) of HDI PCBs to ensure that high-bandwidth video signals can be transmitted without loss of quality, making them indispensable in broadcast and cinematography industries.

Furthermore, medical devices, which require stringent precision and reliability, also benefit from the small feature size and high aspect ratio of these HDI PCBs. Medical imaging equipment, for example, uses high-speed PCB technology to process and deliver clear and detailed images swiftly. The 0.1mm laser drill hole size facilitates the creation of very fine, high-precision circuits necessary for the critical performance of these medical devices.

Aerospace and defense systems, where equipment must operate flawlessly in extreme conditions, also utilize 4L 1+N+1 HDI Boards. These sectors demand electronics that can handle high-speed data transfers and operate reliably under high stress. The robustness of the HDI PCB design, with its high aspect ratio and board thickness options, ensures that critical missions can be supported with the most reliable circuitry available.

In summary, the 4L 1+N+1 HDI Boards are a versatile solution in high-speed PCB applications, ranging from consumer electronics to professional HD SDI converters, medical imaging devices, and even aerospace and defense systems. The advanced HDI PCB manufacturing process that produces these boards with such precise tolerances and high aspect ratios is what enables their use in these demanding scenarios.

Customization:

Experience our premium Product Customization Services tailored specifically for High Density Interconnector (HDI) PCB Boards. Our HDI PCB boards, including the 4L 1+N+1 HDI Boards, are designed to cater to the most intricate and high-speed applications. With an available thickness ranging from 0.4mm to 3.2mm and an impressive aspect ratio of 10:1, we fulfill the requirements for both high speed PCB and high density PCB designs.

We take pride in our PCB customization capabilities, ensuring that your DDR4 PCB needs are met with precision. Our board thickness options extend from 0.2mm to a robust 6.00mm (8mil-126mil), accommodating a diverse range of design specifications and industry standards. Choose our services for a PCB solution that integrates quality, performance, and customization.

Support and Services:

The HDI PCB Board comes with comprehensive product technical support and services designed to assist you in leveraging the full potential of your high-density interconnect PCBs. Our dedicated team of experts is available to provide guidance on product specifications, design optimization, and material selection to ensure your HDI PCB Board performs to the highest standards.

Our technical support services include detailed documentation and resources to assist with board layout, signal integrity analysis, and thermal management strategies. We also offer troubleshooting assistance for any issues that may arise during the manufacturing or assembly process, including advice on soldering techniques, via filling, and surface finishes.

To ensure the longevity and reliability of your HDI PCB Board, we provide recommendations on proper handling, storage, and cleaning procedures. Additionally, we offer insights into the best practices for testing and inspection to maintain the quality and performance of your HDI PCBs throughout their lifecycle.

For complex projects, we can provide personalized support with one-on-one consultations to discuss your specific needs and requirements. Our goal is to facilitate a seamless integration of HDI PCB Boards into your applications, ensuring optimal functionality and efficiency.

Please note that while we strive to offer extensive support, our services do not include on-site assistance or installation. However, we are committed to providing the necessary resources and remote support to help you successfully implement and maintain your HDI PCB Board solutions.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!