Product Description:

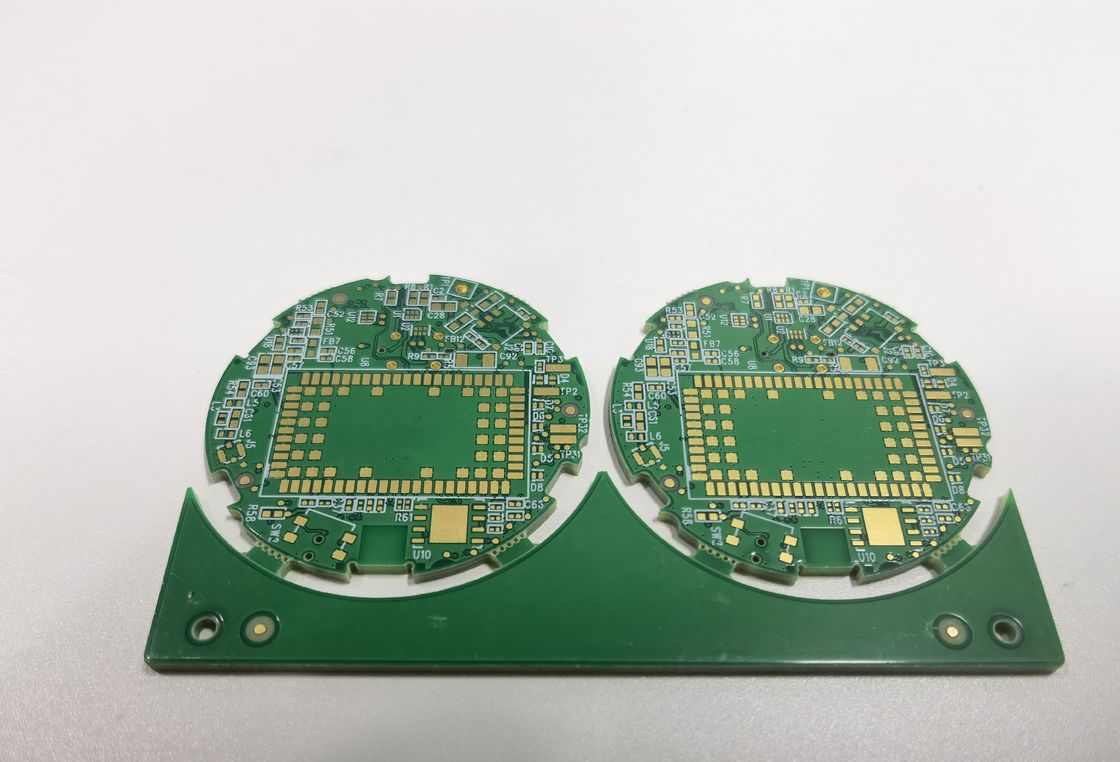

The HDI PCB Board represents the pinnacle of modern printed circuit board (PCB) design, incorporating the latest advancements in High Density Interconnector (HDI) technology. This product stands out in the realm of High Density PCBs, catering to sophisticated electronic devices that demand compact and efficient solutions. With a focus on delivering unparalleled performance and miniaturization, the HDI PCB Board is a testament to the cutting-edge capabilities of HDI PCB Manufacturing.

At the heart of the HDI PCB Board is its exceptional circuitry, characterized by a minimum trace of 3/3Mil. This fine line and spacing technology allows for a higher concentration of trace routing, which is essential in supporting today's complex and high-speed circuitry. This level of miniaturization is a hallmark of High Density PCB design, making it possible to accommodate a greater number of components on a single board without sacrificing performance or reliability.

In terms of construction, the HDI PCB Board boasts a thickness range of 0.4-3.2mm, offering versatility to accommodate various applications and design requirements. This range ensures that the board can be customized to meet the needs of different devices, whether they demand a slim profile for portable electronics or robust construction for industrial applications. The adaptability of this product is a key advantage in HDI PCB Manufacturing, where the ability to tailor the board's physical attributes is crucial for meeting diverse customer needs.

To ensure the highest quality and reliability, each HDI PCB Board undergoes rigorous testing protocols, including 100% E-Testing and X-RAY examination. The 100% E-Testing guarantees that every circuit on the board functions correctly, providing customers with the assurance that each HDI PCB Board will perform to their expectations right out of the box. The X-RAY inspection offers a non-destructive method to inspect the internal features of the board, including hidden layers and microvias, to ensure the integrity of the HDI PCB Board's internal structures.

One of the special requirements that can be accommodated in the production of the HDI PCB Board is the integration of a lamp socket. This feature allows for the direct mounting of light sources onto the board, which can be critical for applications where illumination is necessary, such as backlighting or status indicators. The ability to incorporate special features such as lamp sockets highlights the customizability of High Density PCBs, ensuring that they can meet the specific needs of any application.

The HDI PCB Board is the embodiment of advanced High Density PCB technology, offering a compact, highly reliable solution for a wide range of electronic applications. Its fine line capabilities, customizable thickness, and rigorous testing standards set it apart as a superior choice in the High Density PCB market. With the integration of special requirements like lamp sockets, the HDI PCB Board is not just a product but a comprehensive solution for high-performance, space-constrained electronic devices. When it comes to HDI PCB Manufacturing, this board is a clear example of precision engineering, quality assurance, and the adaptability required to drive innovation in today's fast-paced technology landscape.

Features:

- Product Name: HDI PCB Board

- Min Trace: 3/3Mil

- Key Words: High Density Interconnector, HDI PCB, HDI PCB Board, High Speed PCB Board

- Aspect Ratio: 10:1

- Board Thickness: 0.2mm-6.00mm (8mil-126mil)

- Special Requirements: Lamp Socket

Technical Parameters:

| Parameter |

Specification |

| Minimum Hole Size |

0.15mm |

| Layer Count |

4-20 Layers |

| Hole Size |

0.1mm Laser Drill |

| Testing |

100%E-Testing, X-RAY |

| Raw Material |

FR4 IT180 |

| Aspect Ratio |

10:1 |

| Special Requirements |

Lamp Socket |

| Board Thickness |

0.2mm-6.00mm (8mil-126mil) |

| Pcb Name |

4L 1+N+1 HDI Boards |

| Min Trace |

3/3Mil |

Applications:

The 4L 1+N+1 HDI (High-Density Interconnector) Boards are a pinnacle of modern PCB (Printed Circuit Board) design, marrying the need for compact, high-performance boards with the technological prowess of HDI technology. These boards are meticulously crafted with a minimum trace width and space of 3/3mil, allowing for a higher density of components on a single layer. This makes the HDI PCB an ideal candidate for applications where space is at a premium and performance is critical.

The layer count of these HDI boards ranges from 4 to 20 layers, demonstrating their versatile adaptability to various complex applications. The ability to stack multiple layers with precision ensures that these boards can support intricate circuit designs. One of the standout features of the 4L 1+N+1 HDI Boards is the minimum hole size of 0.15mm, which facilitates the inclusion of micro-vias that are essential for high-speed signal transmission, making these boards highly sought after as High-Speed PCB Boards.

Constructed from high-quality FR4 IT180 raw material, these HDI PCBs guarantee excellent thermal resistance and mechanical robustness, which are vital for maintaining the integrity of high-speed signals. This makes the product suitable for high-speed PCB board applications across a range of industries, including telecommunications, where signal integrity can make or break the performance of the network.

The product application occasions and scenarios for the 4L 1+N+1 HDI Boards are varied and extensive. In the realm of consumer electronics, where devices are getting sleeker and more powerful, the High Density PCB is indispensable for smartphones, tablets, and laptops. In the automotive industry, these boards are crucial for the reliable operation of in-vehicle infotainment systems, navigation, and driver assistance systems, all of which require high-speed data transmission.

In the medical field, where precision and reliability are non-negotiable, the 4L 1+N+1 HDI Boards are used in critical diagnostic and imaging equipment. Aerospace applications also benefit from the high density and high-speed capabilities of these PCBs, where they are used in satellite communication systems and avionics. Furthermore, in the burgeoning field of IoT (Internet of Things), these boards provide the backbone for the myriad of connected devices requiring miniaturization without compromising on speed or connectivity.

In summary, the 4L 1+N+1 HDI Boards are a versatile, high-performance solution for a plethora of high-speed PCB board applications where reliability, density, and precision are the keys to advancement and innovation in today's technology-driven world.

Customization:

Our HDI Printed Circuit Boards are designed with precision to cater to your most complex and high-speed PCB board requirements. With a flexible layer count ranging from 4 to 20 layers, we can tailor your HDI PCB Board to match the exact needs of your application.

We understand the importance of precision in circuitry, which is why we offer a minimum hole size of 0.15mm, ensuring that your HDI Printed Circuit Boards are equipped for fine-pitch technology. Our boards boast an impressive aspect ratio of 10:1, exemplifying our commitment to quality and reliability.

For specialized applications, we provide customizations such as half holes and the accommodation of 0.25mm BGA for your High Speed PCB Board needs. These special requests are handled with the utmost attention to detail to meet your specific design criteria.

Quality assurance is paramount in the production of our HDI Printed Circuit Boards. Therefore, we conduct 100% E-Testing and X-RAY examinations to ensure that each board meets our high standards for performance and reliability. Trust us to deliver HDI PCB Boards that are not only customized but also thoroughly tested for your peace of mind.

Support and Services:

Thank you for choosing our High-Density Interconnect (HDI) PCB Board. We are committed to providing you with the highest level of technical support and services to ensure your satisfaction with our product. Our product technical support includes a comprehensive range of services designed to address any questions or issues you may encounter.

Our technical support services for the HDI PCB Board include:

- Online Troubleshooting Guide: Access our detailed online troubleshooting guide, which provides step-by-step solutions to common issues you may experience with your HDI PCB Board.

- FAQs: Our Frequently Asked Questions (FAQs) section covers a wide range of topics that will help you better understand your HDI PCB Board and how to get the most out of it.

- Product Documentation: Download the latest product manuals, technical specifications, and datasheets directly from our website to stay informed about your HDI PCB Board.

- Firmware Updates: Keep your HDI PCB Board up to date with the latest firmware updates available for download from our support portal.

- Community Forum: Join our community forum to connect with other HDI PCB Board users, share experiences, and find answers to your questions.

If you require further assistance or have more complex issues, our team of expert technicians is ready to provide you with personalized support. We strive for excellence in our support services to ensure your HDI PCB Board operates at its best.

Please note that our technical support and services exclude any direct contact information. All support is provided through our online resources and community forum. We encourage you to utilize these tools for a fast and efficient resolution to your queries.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!