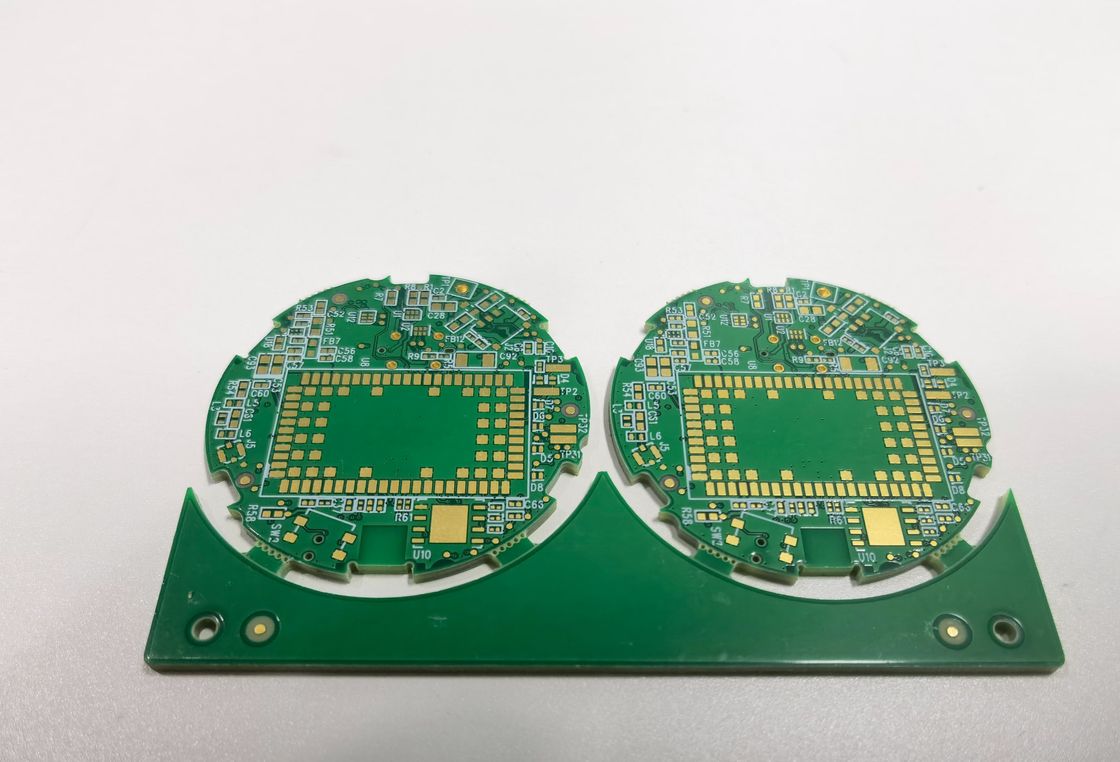

Advanced 4-Layer Hdi Pcb Boards With Impedance Control Density Interconnector X Ray Testing

Product Description:

The HDI PCB Board represents the pinnacle of modern printed circuit board (PCB) technology, where high density interconnect (HDI) design strategies are employed to create an advanced, high speed PCB that meets the stringent requirements of complex electronic devices. Our HDI PCB Board has been meticulously crafted to provide a reliable foundation for applications demanding a combination of compact dimensions, enhanced performance, and superior signal integrity. This product summary will elaborate on the attributes, special requirements, and testing protocols that make our HDI PCB Board an exceptional choice for your electronics projects.

Beginning with the special requirements, our HDI PCB Board has been designed to accommodate a lamp socket, which is a critical feature for lighting applications and electronic devices that require a secure and stable connection to a light source. The lamp socket integration is a testament to the customizability of our HDI PCBs, allowing them to meet specific needs while maintaining the highest standards of design and manufacturing.

One of the most significant attributes of the HDI PCB Board is the range of board thicknesses available. Customers can select between 0.2mm and 6.00mm (8mil to 126mil), providing great flexibility in terms of mechanical strength and application suitability. Whether you are working on a lightweight, portable device or a robust, industrial component, there is an HDI PCB Board thickness that aligns perfectly with your requirements.

When it comes to the precision of the PCB's layout, the HDI PCB Board boasts a minimum trace width and spacing of 3/3mil. This minuscule trace geometry is a testament to the high density aspect of the PCB, enabling more circuitry to be packed into a smaller area. This capability is crucial for achieving the high-speed signal transmission required by advanced electronic components, and for supporting the ever-increasing demands for miniaturization in the electronics industry.

Our HDI PCB Board undergoes rigorous testing to ensure reliability and functionality. Every board is subject to 100% electrical testing (E-testing) to verify that it meets the electrical specifications and to detect any potential defects. Additionally, X-ray inspection is employed to examine the integrity of internal structures, such as vias and solder joints, which are not visible to the naked eye. These testing protocols are vital for maintaining quality and performance in high density PCBs.

Special requests can also be accommodated to meet the unique demands of various applications. Our HDI PCB Board can be manufactured with half holes, which are essential for certain types of edge connectors and mounting requirements. Moreover, we cater to high precision applications with a 0.25mm ball grid array (BGA) pitch, enabling the connection of integrated circuits with a multitude of I/O pins in a very small footprint. This feature is particularly important for high speed PCB designs that require a large number of connections in a compact space.

In summary, our HDI PCB Board is a versatile, high-performance solution that excels in applications requiring high density and high speed circuitry. With the ability to integrate a lamp socket, a wide range of board thicknesses, tight trace geometries, comprehensive testing, and the capability to fulfill special requests such as half holes and fine-pitch BGAs, this HDI PCB Board stands out as a superior choice for designers and engineers seeking the best in PCB technology. Whether for sophisticated consumer electronics, critical medical devices, or demanding industrial applications, our HDI PCB Board delivers the reliability, performance, and advanced features necessary to drive innovation and efficiency in your electronic projects.

Features:

- Product Name: HDI PCB Board

- Board Thickness: 0.2mm-6.00mm (8mil-126mil)

- Layer Count: 4-20 Layers

- Special Request: Half Hole, 0.25mm BGA

- Testing: 100% E-Testing, X-RAY

- Aspect Ratio: 10:1

- HDI PCB Manufacturing: High-Density Interconnect PCB with precise features

- High Speed PCB Board: Designed for high-speed electronic applications

Technical Parameters:

| Parameter |

Details |

| Thickness |

0.4-3.2mm |

| Min Trace |

3/3Mil |

| Raw Material |

FR4 IT180 |

| Board Layer |

6L |

| Testing |

100%E-Testing, X-RAY |

| Layer Count |

4-20 Layers |

| Board Thickness |

0.2mm-6.00mm (8mil-126mil) |

| Impedance Control |

Yes |

| Special Request |

Half Hole, 0.25mm BGA |

| Aspect Ratio |

10:1 |

Applications:

The HDI (High Density Interconnect) PCB Board is a high-performance circuit board designed to meet the rigorous demands of advanced electronic devices. With a minimum trace of 3/3Mil, this product offers superior precision for intricate circuit designs. It is particularly suitable for applications where high signal integrity is crucial, thanks to its impedance control feature. The HDI PCB board is adaptable in its use, with an aspect ratio of 10:1 and a range of board thickness from 0.2mm to 6.00mm (8mil to 126mil). It is constructed using the high-quality FR4 IT180 raw material, which ensures durability and reliability in various operating conditions.

One of the primary applications for the HDI PCB board is within the realm of HD SDI converters. These converters are used to translate high-definition serial digital interface signals, which are common in professional video and audio environments. The precise trace dimensions and impedance control of the HDI PCB make it an ideal candidate for such converters, ensuring minimal signal loss and high fidelity in signal transmission.

In the field of consumer electronics, the HDI PCB is integral in developing compact, high density model boards that are used in smartphones, tablets, and laptops. Its ability to support a high number of connections per unit area makes it a perfect fit for devices where space is at a premium and functionality cannot be compromised. As gadgets continue to shrink in size while growing in complexity, the HDI PCB's capabilities become even more valuable.

Furthermore, the HDI PCB board also finds applications in medical devices, aerospace technology, and military systems, where its high reliability and robustness are essential. In medical devices, for example, the HDI PCB can be used in sophisticated diagnostic equipment, wearables that monitor health metrics, and miniature implants. In aerospace and military applications, the high-density nature of the board, coupled with its ability to function reliably under extreme conditions, makes it a component of choice for mission-critical systems.

Overall, the HDI PCB Board is a versatile product that caters to a multitude of applications across various industries, driven by its design to accommodate high-density circuits with precision and stability. Its use in HD SDI converters, high density model boards, and other advanced electronic systems underscores its importance in the ongoing evolution of technology.

Customization:

Explore our premium High Density Interconnector (HDI) PCB Board services, designed to cater to the most demanding high-speed applications. Our cutting-edge HDI technology ensures that your High Speed PCB Board operates at peak performance with a layer count ranging from 4-20 layers, accommodating the complexities of modern electronics.

With an impressive aspect ratio of 10:1, our HDI PCB boards provide the reliability and durability needed for High Speed PCB Board applications. We understand that precision is key, which is why we offer specialized customization options such as half holes and support for 0.25mm BGA to meet your specific design requirements.

Introducing our specialized 4L 1+N+1 HDI Boards, the perfect solution for your high-speed circuitry needs. Trust in our High Speed PCB Board customization services to deliver the performance and quality your projects demand.

Support and Services:

Our HDI PCB Board comes with comprehensive technical support and services designed to ensure the best possible experience with our product. We are committed to providing assistance with any technical queries or issues that may arise.

Technical Support Services for the HDI PCB Board include:

- Product Documentation – Detailed guides and manuals are available to help you understand the features and specifications of the HDI PCB Board.

- Installation Assistance – Step-by-step support to help you install your HDI PCB Board correctly and safely.

- Troubleshooting – Assistance in diagnosing and resolving any operational issues that you encounter with the board.

- Firmware Updates – Information and access to the latest firmware updates to ensure your HDI PCB Board operates at peak performance.

- Technical Inquiry – Dedicated support for any technical questions regarding the HDI PCB Board's capabilities and integration.

Please note that while we strive to provide comprehensive support, certain services may be subject to availability and may change over time. We encourage customers to refer to our official website or contact our customer service team for the most current information regarding support and services for the HDI PCB Board.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!