Features:

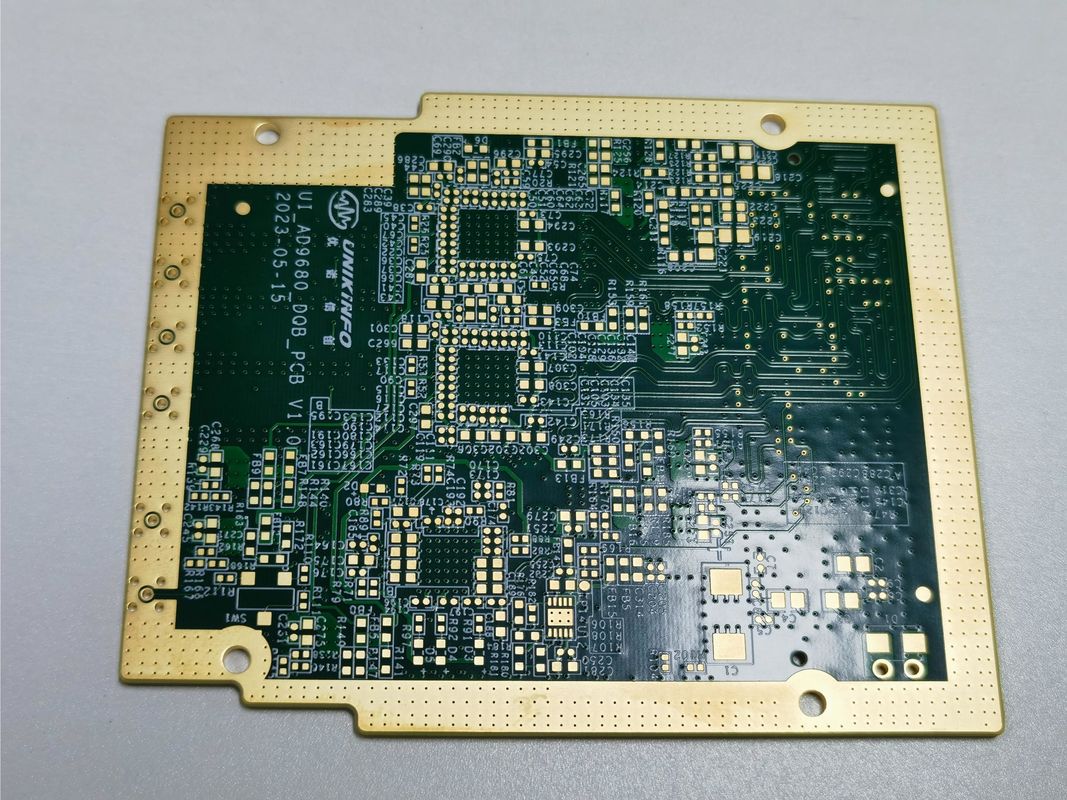

- Product Name: HDI PCB Board

- Minimum Hole Size: 0.15mm

- Key Words: High Density Interconnector, HD SDI Converter, High Speed PCB

- Thickness: 0.4-3.2mm

- Board Thickness: 0.2mm-6.00mm (8mil-126mil)

- Min Trace: 3/3Mil

Technical Parameters:

| Attribute |

Value |

| Aspect Ratio |

10:1 |

| Board Layer |

6-32L |

| Key Words |

High Density Interconnector |

| Hole Size |

0.1mm Laser Drill |

| Min Trace |

3/3Mil |

| Special Request |

Half Hole, 0.25mm BGA |

| Pcb Name |

4L 1+N+1 HDI Boards |

| Layer Count |

4-20 Layers |

| Raw Material |

FR4 IT180 |

| Testing |

100%E-Testing,X-RAY |

Applications:

HDI Printed Circuit Boards (PCBs) are at the forefront of modern electronics, offering increased circuitry density and facilitating the miniaturization of devices. With a minimum hole size of 0.15mm, these boards are designed for precision and high-level functionality. The specific HDI PCB board under discussion is tailored to meet the demands of various applications, with its ability to accommodate board layers ranging from 6 to 32L and an aspect ratio of 10:1.

One of the primary application scenarios for this HDI PCB board is in the realm of advanced computing devices. High-Density Model Boards are integral in servers, laptops, and smartphones where the need for a high speed PCB board is paramount to handle the rapid data processing and heat dissipation requirements. The compact and efficient design of the HDI PCB allows for a sleeker product build without compromising on performance.

In the field of communication, these boards are extensively used due to their high-speed signal transmission capabilities. Devices such as routers, switches, and high-frequency signal transmission systems rely on the HDI PCB to ensure stability and efficiency. The precision offered by the minimum hole size of 0.15mm ensures that high-density interconnections are reliable and effective, which is crucial for maintaining connectivity in critical communication infrastructures.

Special requirements such as lamp socket integration are also a testament to the versatility of the HDI PCB board. This feature is particularly useful in LED lighting systems and smart lighting solutions where space is at a premium, and reliability is non-negotiable. The HDI PCB can seamlessly integrate with these systems, providing a solid foundation for the intricate electronic components and connectors needed for modern lighting technology.

The HDI PCB's reliability is further ensured through rigorous testing protocols, including 100% E-Testing and X-RAY examination. These testing methods guarantee that every board meets the highest standards of quality and performance before being deployed in any application. Such thorough testing is especially critical in medical devices and aerospace applications, where the HDI PCB board must operate flawlessly under extreme conditions and where the stakes for failure are exceptionally high.

In summary, the HDI PCB board's design, characterized by its minimal hole size, special requirements accommodation such as lamp sockets, and a high aspect ratio, make it an indispensable component in various high-tech applications. Its adaptability and reliability are why the HDI PCB remains a cornerstone in the development of High-Speed PCB Boards, powering the next generation of electronic innovations.

Customization:

Our HDI Printed Circuit Boards offer a range of Product Customization Services designed to meet the highest standards of precision and quality. We ensure 100% E-Testing and X-RAY verification for each HDI PCB Board, guaranteeing flawless functionality and reliability. With a minimum trace specification of 3/3Mil, our HDI Printed Circuit Boards can accommodate the most intricate designs and complex circuitry.

The available thickness for our HDI PCB Board ranges from 0.4 to 3.2mm, providing versatility for a variety of applications. In addition, our advanced laser drilling capabilities allow us to achieve hole sizes as small as 0.1mm, ensuring high-density interconnectivity and compact board dimensions.

Furthermore, our HDI Printed Circuit Boards boast an impressive aspect ratio of 10:1, enabling efficient connections between layers in multi-layer PCBs. This attribute is particularly beneficial for high-performance electronic devices that require a large number of interconnects in a constrained space.

Support and Services:

Our HDI PCB Board product comes with comprehensive technical support and services to ensure your satisfaction and the optimal performance of the product. Our support includes:

- Detailed Product Documentation: Access a thorough guide and technical specifications to understand the capabilities and features of your HDI PCB Board.

- Online Knowledge Base: Utilize a rich online resource with articles, FAQs, and troubleshooting tips to help you solve common issues and enhance your understanding of the product.

- Firmware Updates: Keep your HDI PCB Board up-to-date with the latest firmware updates to improve functionality and add new features.

- Technical Assistance: Receive expert technical support for any queries or issues you might encounter with your HDI PCB Board. Our team is dedicated to providing timely and effective solutions.

- Repair and Maintenance Services: Benefit from our repair services to address any physical damage or technical malfunctions, ensuring your HDI PCB Board operates at its best.

- Training and Education: We offer training sessions to help you and your team effectively use and maintain the HDI PCB Board, maximizing its potential in your applications.

- Community Support: Join our user community to connect with other HDI PCB Board users, share experiences, and learn from one another.

We are committed to delivering exceptional support and services to complement our high-quality HDI PCB Board product. Our goal is to ensure you have all the resources you need for a smooth and successful experience.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!