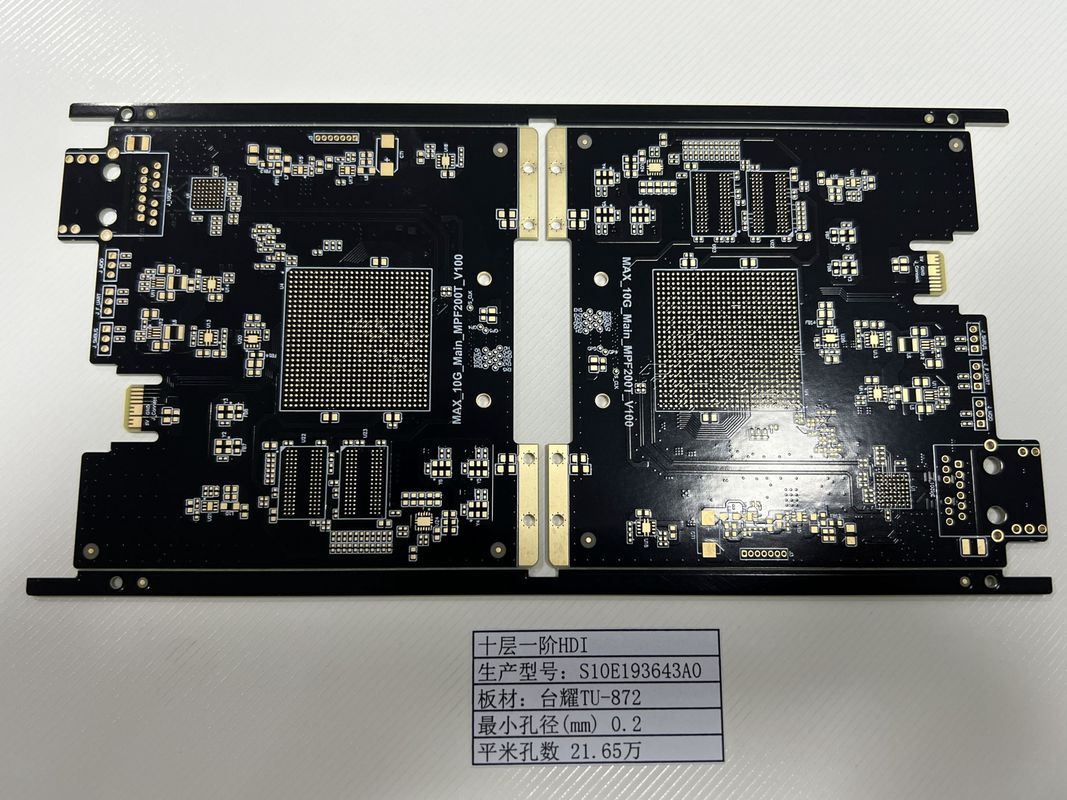

FR4 TU-872 Hight speed PCB 10 Layers 3/3Mil Density Interconnector PCB 4L 1 N 1 HDI Boards ENIG IP4452

Product Description:

The HDI PCB Board is a state-of-the-art High Density Interconnector (HDI) Printed Circuit Board designed for applications where high performance, reliability, and precision are paramount. Meticulously crafted using advanced manufacturing techniques, this HDI PCB Board is ideal for the latest generation of electronic devices that demand high-speed data transfer and high levels of integration, such as high-speed computing systems utilizing DDR4 PCB technology.

With a highly customizable layer count ranging from 4 to 20 layers, the HDI PCB Board caters to a wide array of design complexities and application requirements. For even more demanding projects, there is an option to extend the board layer count up to 32L (6-32L), providing unparalleled flexibility in circuit design and space allocation. This capacity is particularly beneficial for sophisticated, multi-functional devices that require additional layers for signal integrity and circuit density.

The HDI PCB Board boasts an impressive minimum hole size of 0.15mm, enabling ultra-fine pitch and high-density component placement. This feature is indispensable for modern High Speed PCB applications, where the minimization of space between components is crucial for both performance and miniaturization. The precision drilling also ensures that the board can accommodate advanced micro-vias, which are essential for layer transitions in multi-layer HDI designs.

Constructed from high-grade FR4 IT180 raw material, the HDI PCB Board delivers exceptional thermal resistance, mechanical durability, and electrical insulation. The IT180 material is well-regarded for its high glass transition temperature, which ensures that the PCB can withstand the high temperatures associated with lead-free soldering processes and high-speed operation without compromising its structural integrity or electrical performance.

One of the remarkable special requests available for this HDI PCB Board is the inclusion of half holes, also known as castellated holes. These half holes are meticulously crafted to connect the board to various components or other PCBs, enabling modularity and ease of integration within complex multi-board systems. This feature can be advantageous for applications such as stackable computer modules or removable peripherals that require a reliable and reusable electrical interface.

Moreover, the HDI PCB Board is specifically designed to support 0.25mm Ball Grid Array (BGA) technology, which is crucial for achieving high-density component placement. BGA packages are favored for their reduced inductance and better heat conduction, which are essential for high-speed and high-power applications. The 0.25mm BGA pitch aligns seamlessly with the latest DDR4 PCB designs, facilitating the use of contemporary memory modules and chipsets that demand precise BGA alignments.

The HDI PCB Board exemplifies state-of-the-art engineering and manufacturing excellence, making it an ideal choice for developers and engineers looking to harness the capabilities of HDI technology for their next-generation electronic products. Whether it's for high-speed data applications, DDR4 memory solutions, or any other application that requires a compact, high-performance PCB, this HDI PCB Board delivers on all fronts. With its combination of advanced features and robust material properties, it stands as a benchmark for high-quality, high-speed PCB solutions in the electronics industry.

Features:

- Product Name: HDI PCB Board

- Layer Count: 4-20 Layers

- Board Thickness: 0.2mm-6.00mm (8mil-236mil)

- Minimum Thickness: 0.4mm

- Maximum Thickness: 3.2mm

- Hole Size: 0.1mm Laser Drill

- Key Words: High Density Interconnector, High Speed PCB Board, High Density PCB

Technical Parameters:

| Parameter |

Specification |

| Aspect Ratio |

10:1 |

| Impedance Control |

Yes |

| Key Words |

High Density Interconnector (HDI) |

| Special Request |

Half Hole, 0.25mm BGA |

| Minimum Hole Size |

0.15mm |

| Raw Material |

FR4 IT180 |

| Min Trace |

3/3Mil |

| Testing |

100%E-Testing, X-RAY |

| Special Requirements |

Lamp Socket |

| Board Thickness |

0.2mm-6.00 mm (8mil-126mil) |

Applications:

The HDI PCB Board, with its impressive range of attributes, is tailored to meet the high demands of precision electronic applications. Featuring a thickness spectrum of 0.4-3.2mm, these boards are versatile and can be integrated into a multitude of devices, catering to a wide range of product sizes and complexities. The rigorous impedance control ensures signal integrity is maintained across various frequencies, making the HDI PCB Board ideal for applications where performance is critical.

One of the primary application occasions for the HDI PCB Board is within HD SDI Converters. These converters are crucial in professional video industries, such as broadcasting and film production, where they convert HD digital video signals without compromising on quality. The minimum trace width and spacing of 3/3Mil on the HDI PCB allows for high-density component placement, essential in the compact and efficient design of HD SDI Converters. This compactness is further supported by the special request feature of half holes and 0.25mm BGA, enabling the attachment of small-scale components with minimal footprint.

Every HDI PCB Board undergoes 100% E-Testing and X-RAY inspections to guarantee defect-free boards. This level of testing is crucial in high-reliability scenarios, such as aerospace, military, and medical devices, where the HDI PCB must perform flawlessly under stringent conditions. In these scenarios, the board's reliability and the accuracy of signal transmission are paramount.

Moreover, the HDI PCB Board's attributes make it an excellent choice for modern smart devices and portable electronics. The thinness and controlled impedance are ideal for sleek smartphones, tablets, and wearables, where space is at a premium, and power efficiency is essential. In these consumer electronics, the HDI PCB enables the dense packing of components necessary to deliver the multifunctionality that users demand in today's market.

In summary, the HDI PCB Board is a cutting-edge solution for a variety of high-tech applications. Its design considerations of thickness, impedance control, minimal trace dimensions, and specialized features such as half holes and 0.25mm BGA, make it an adaptable and reliable option for everything from HD SDI Converters to critical aerospace components and compact consumer electronics. As technology advances, the role of the HDI PCB in enabling innovation and driving product performance continues to grow.

Customization:

Our Product Customization Services offer a premium range of HDI PCBs, including our top-of-the-line 4L 1+N+1 HDI Boards. These High Density Interconnector PCBs are expertly crafted using the finest FR4 IT180 raw materials, ensuring a robust and reliable foundation for your electronics.

The 4L 1+N+1 HDI Boards boast an impressive aspect ratio of 10:1, accommodating a layer count that ranges from 4 to 20 layers. This flexibility allows us to cater to a variety of High Density PCB needs and applications, ensuring that our HDI PCB Manufacturing processes meet the exact requirements of your project.

Choose our HDI PCB services for your next project and experience the perfect blend of quality, performance, and customization. Our commitment to excellence is evident in every HDI PCB we produce, setting the industry standard for high density, complex circuitry solutions.

Support and Services:

Our HDI PCB Board is designed with the latest in high-density interconnect technology, ensuring superior performance for the most demanding applications. We are committed to providing exceptional technical support and services to ensure the success of your projects.

The technical support for our HDI PCB Board includes a comprehensive knowledge base with detailed documentation and resources to assist you in design, implementation, and troubleshooting. Our team of experienced engineers is available to provide guidance and answer any questions related to the HDI PCB Board.

Our services encompass design review and recommendations to optimize the performance and manufacturability of your HDI PCB designs. We also offer prototype services to test and validate your designs before full-scale production.

To ensure the longevity and reliability of your HDI PCB Board, we provide guidelines on proper handling, storage, and maintenance practices. In addition, we offer services for board repair and rework in the event of any issues during the lifecycle of the product.

We are dedicated to continuous improvement and welcome customer feedback on our products and services. Our team is constantly working to enhance our support resources and provide you with the best possible experience with our HDI PCB Board.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!