Advanced Density Interconnector HDI PCB Board 10 1 Aspect Ratio 6-32L Impedance Control 100% E Testing

Product Description:

The 4L 1+N+1 HDI Boards represent a significant advancement in the field of High Density PCB technology. HDI Printed Circuit Boards, standing for High-Density Interconnector PCBs, are at the forefront of the electronics industry, catering to the growing demand for compact yet efficient electronic devices. Our HDI PCB Board product is a testament to this revolutionary technology, which allows for a more complex circuitry in a smaller space without compromising performance.

At the heart of the 4L 1+N+1 HDI Boards is the robust aspect ratio of 10:1. This high aspect ratio signifies the board's capability to support holes that are ten times deeper than their diameter. Such a feature is critical when it comes to accommodating more connection points on the PCB, thereby enabling the creation of High Density Model Boards that are compact but do not skimp on functionality or connectivity.

The hole size is another critical measure of the board's sophistication. Our HDI PCB Board boasts a minuscule hole size of 0.1mm, achieved through precision Laser Drill technology. This allows for the creation of micro-vias that are essential for the multi-layering of circuits, an intrinsic characteristic of High Density PCBs. These micro-vias enable interconnections between the layers of the PCB, which is especially advantageous in electronic devices where space saving is paramount.

The PCB Name, 4L 1+N+1 HDI Boards, indicates the board's configuration, which is a 4-layer structure with a unique lamination process. This process involves one build-up of high-density interconnection layers. This allows for a more reliable interconnection between the traditional PCB layers, further enhancing the potential for miniaturization and complexity in electronic devices. The 1+N+1 designation is a key element of the HDI structure, enabling designers to achieve a higher wiring density per unit area.

In terms of board layer options, the HDI PCB Board is highly versatile, with available configurations ranging from 6 to 32 layers (6-32L). This broad range ensures that the product can be tailored to the specific needs of various applications, whether it requires a simpler six-layer board or a more complex 32-layer design. The ability to stack multiple layers with high-density interconnection makes these HDI Printed Circuit Boards ideal for a wide array of sophisticated electronic applications.

Additionally, the physical robustness of the HDI PCB Board is reflected in its thickness options, which span from a slim 0.4mm to a sturdy 3.2mm. This range of thicknesses not only accommodates the physical requirements of different devices but also plays a role in the thermal and mechanical stability of the PCB. A thinner board could be desirable for ultra-thin electronic devices, whereas a thicker board could be preferred for its durability and heat dissipation properties.

In conclusion, the 4L 1+N+1 HDI Boards are a symbol of innovation in High Density Model Board production. With a commendable aspect ratio of 10:1, precise 0.1mm Laser Drill hole sizing, and a versatile board layer range of 6-32L, these boards are crafted to meet the exacting demands of modern electronics. The thickness options from 0.4 to 3.2mm further enhance the product's adaptability to various applications. Whether it is for smartphones, tablets, medical devices, or industrial equipment, our HDI Printed Circuit Boards stand ready to deliver high performance in a miniaturized package, truly embodying the cutting-edge of High Density PCB technology.

Features:

- Product Name: HDI PCB Board

- Special Requirements: Lamp Socket

- Special Request: Half Hole, 0.25mm BGA

- Thickness: 0.4-3.2mm

- Key Words: High Density Interconnector, HDI Printed Circuit Boards, HDI PCB, DDR4 PCB

- Raw Material: FR4 IT180

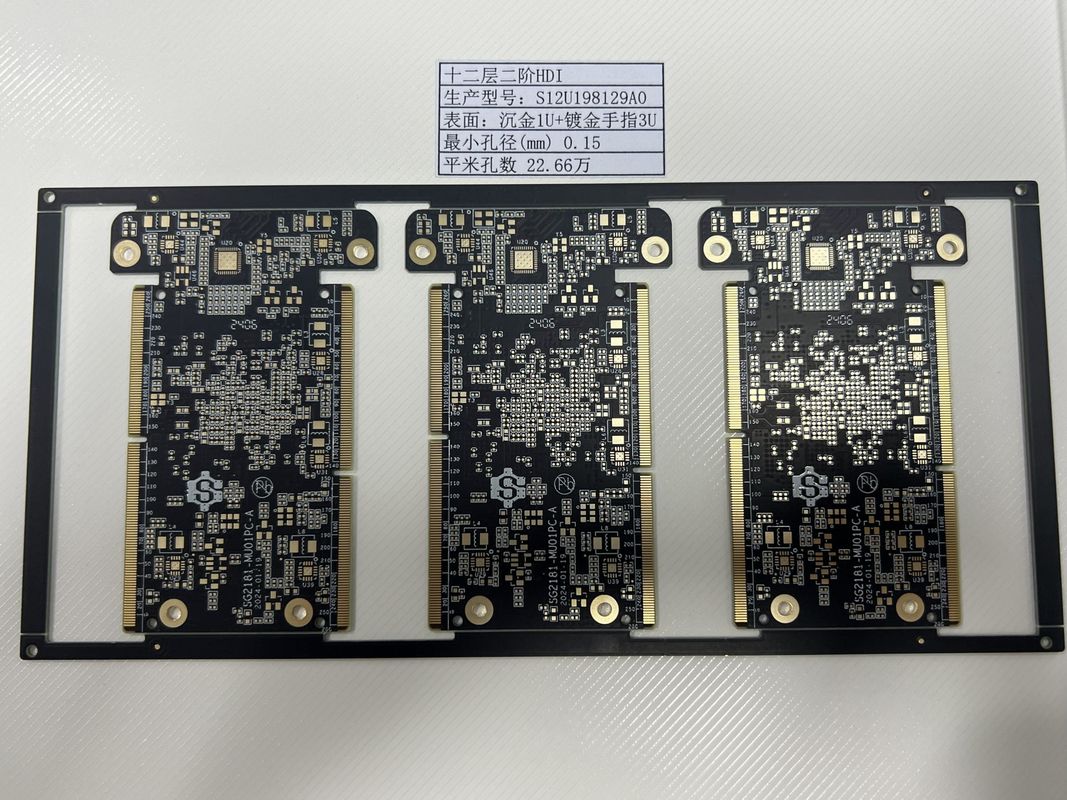

Technical Parameters:

| Parameter |

Specification |

| PCB Name |

12L 2+N+2 HDI Boards |

| Min Trace |

3/3Mil |

| Impedance Control |

Yes |

| Aspect Ratio |

10:1 |

| Thickness |

0.4-3.2mm |

| Minimum Hole Size |

0.15mm |

| Special Request |

Half Hole, 0.25mm BGA |

| Testing |

100%E-Testing, X-RAY |

| Hole Size |

0.1mm Laser Drill |

| Raw Material |

FR4 IT180 |

Applications:

The 4L 1+N+1 HDI (High Density Interconnect) PCB Boards are a quintessential component in modern electronics due to their high-quality attributes, including 100% E-Testing and X-RAY verification, a thickness range of 0.4-3.2mm, an impressive aspect ratio of 10:1, and a precise 0.1mm laser-drilled hole size. These characteristics make them highly sought after in various application occasions and scenarios where precision, reliability, and performance are paramount.

One of the main application scenarios for these HDI PCB boards is in the realm of DDR4 PCBs. DDR4 memory modules are ubiquitous in computers and require PCBs that can handle high-speed data transfer while maintaining signal integrity. The precise laser drilling and high aspect ratio of these HDI PCB boards allow for closer trace routing which is necessary for the high-speed requirements of DDR4 memory. Furthermore, the comprehensive E-Testing ensures that each board meets the stringent electrical performance standards required for DDR4 applications.

Besides memory modules, HDI PCB boards are also integral in various High-Speed PCB applications. These include networking devices such as routers, switches, and modems, where signal integrity at high data rates is crucial. The minimal hole size and high aspect ratio facilitate the design of compact, multi-layered boards that can accommodate the dense packaging of components required in these high-speed devices. The robust testing protocols ensure the reliability and functionality of the boards even under the stress of high-speed data traffic.

Another important application of the 4L 1+N+1 HDI PCB boards is in mobile devices and smartphones. As devices become thinner and more powerful, the demand for compact, high-performance PCBs increases. The slim profile of the HDI PCB board, combined with its ability to support a high connection density, makes it an ideal solution for the small form factors of mobile technology. The thorough E-Testing and X-RAY inspection are critical in ensuring that each board functions correctly without adding unnecessary bulk to the device.

Furthermore, these HDI PCB boards are also suitable for use in medical devices and aerospace electronics, where reliability and precision are non-negotiable. The high aspect ratio and fine hole size allow for the integration of more functions in a smaller space, which is often a requirement in these industries. The stringent testing guarantees that the boards can operate reliably in environments where failure is not an option.

In conclusion, the 4L 1+N+1 HDI Boards are versatile and essential components for industries demanding high-density interconnect solutions. Their robust testing, thickness versatility, and precise drilling make them suitable for DDR4 PCBs, High-Speed PCB applications, and much more, ensuring they are a top choice for designers seeking performance and reliability in their electronic products.

Customization:

At our state-of-the-art HDI PCB Manufacturing facility, we specialize in the production of High Density Interconnector (HDI) PCB Boards. Our product customization services ensure that each HDI PCB is tailored to meet your specific needs, including special requirements such as lamp socket integration.

Our HDI PCBs are crafted using top-quality FR4 IT180 raw material, which provides exceptional thermal resistance and mechanical strength. We accommodate a wide range of designs with our capability to produce boards with layer counts ranging from 4 to 20 layers, depending on your project's complexity.

To meet the demands of modern electronics, our High Density Model Boards can be customized with a minimum hole size of 0.15mm, allowing for higher component density and more compact designs. Trust in our expertise to deliver HDI PCBs that align with the highest standards of quality and reliability.

Support and Services:

The HDI PCB Board is designed with high-density interconnect technology, ensuring superior performance and reliability for demanding applications. Our Product Technical Support and Services are committed to providing you with the necessary assistance to maximize the functionality and lifespan of your HDI PCB Board. Our services include:

Technical Support: Our team of experienced engineers is available to provide you with expert advice on design considerations, material selection, and layout optimizations for your HDI PCB Board. We can assist with technical queries to ensure your product meets its intended specifications and performance requirements.

Documentation: Comprehensive documentation is available to support your HDI PCB Board. This includes detailed specifications, user manuals, application notes, and design guidelines to facilitate the correct usage and integration of the board into your projects.

Design Review Services: Before you proceed to the manufacturing phase, our design review services can help identify potential issues that could affect the performance or manufacturability of your HDI PCB Board. We aim to ensure that your design is optimized for both quality and cost-efficiency.

Quality Assurance: We adhere to strict quality control standards to ensure that every HDI PCB Board meets our high-quality benchmarks. Our quality assurance processes include rigorous testing and inspection to guarantee that you receive a product that performs to your expectations.

After-Sales Support: Following your purchase of the HDI PCB Board, our after-sales support team is here to assist with any post-purchase inquiries or issues. We are dedicated to your satisfaction and are ready to provide guidance on product use, maintenance, and troubleshooting.

Repair and Rework Services: Should your HDI PCB Board require repairs or modifications, our repair and rework services are designed to address and resolve such needs with minimal downtime. We strive to return your product to its optimal operating condition as quickly as possible.

Upgrade Advice: As technology progresses, we provide recommendations on upgrades and improvements to ensure that your HDI PCB Board remains current and compatible with new advancements in the field. Our team can guide you through any necessary updates to keep your board at the forefront of technology.

Our commitment to delivering exceptional support and services is unwavering. We are here to ensure that your experience with the HDI PCB Board is both successful and satisfying.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!