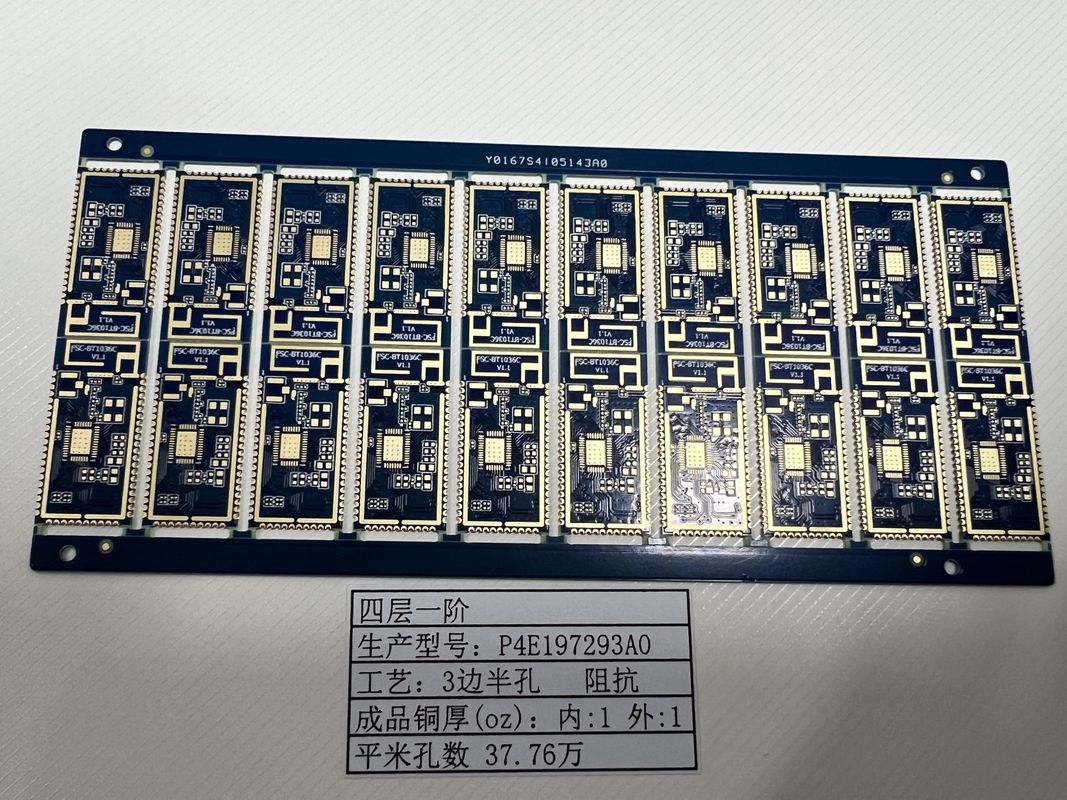

Aspect Ratio FR4 It180 Hdi Pcb Board 4-20 Layers 0.1Mm Min Hole Size Half hole ISOLA 370HR

Product Description:

The HDI PCB Board is a cutting-edge solution, tailored for applications that demand high-density interconnect technology. As an integral component in modern electronics, this 6-layer (6L) board is designed to meet and exceed the complex requirements of high-speed PCB systems. HDI PCBs, or High-Density Interconnect Printed Circuit Boards, are renowned for their improved performance and reliability, which are essential in today’s fast-paced technology landscape.

One of the standout features of our HDI PCB Board is the precision with which it is manufactured. The board boasts Impedance Control, a critical attribute for high-speed PCB designs. Impedance control is a measure of the opposition that a circuit presents to the passage of a current when a voltage is applied. In high-speed circuitry, controlling the impedance is vital for maintaining signal integrity, reducing noise, and ensuring the overall performance of the electronic device. Our advanced manufacturing processes ensure that the impedance is maintained to exact specifications, thus guaranteeing the efficient operation of the HDI PCB.

When it comes to the creation of micro-vias and the placement of components, our HDI PCB Board demonstrates exceptional capabilities, featuring a Hole Size of 0.1mm Laser Drill. This allows for the high-precision drilling of micro-vias, which are integral to achieving the high-density interconnects that these boards are named for. These smaller vias enable the creation of more compact, yet more powerful, electronic assemblies. They also allow for more layers to be incorporated into the design, which is a significant benefit of using an HDI PCB.

As technology progresses, the demand for smaller and more efficient components increases. In response to this, our HDI PCB Board includes a Special Request feature of Half Hole and 0.25mm BGA (Ball Grid Array) technology. The half-hole technique is utilized for edge mounting of PCBs to create module-like configurations, while the 0.25mm BGA provides superior connectivity in a significantly reduced space. This is particularly important for applications that require a large number of I/Os in a small form factor, such as in mobile devices and high-speed computing hardware.

The versatility of our HDI PCB Board is further enhanced by its variable Thickness range of 0.4-3.2mm. This range allows for flexibility in the design and application of the board, making it suitable for a multitude of different electronic devices. Whether the end application requires a thin, flexible board for wearables or a more robust board for industrial applications, our HDI PCB can be customized to fit the specific needs of the project.

In summary, the HDI PCB Board is an exceptional choice for any application that requires a high-speed PCB with advanced features. It combines 6 layers of high-density interconnect technology with precise impedance control and the ability to incorporate a diverse range of components through features like 0.1mm Laser Drill holes and 0.25mm BGA. The inclusion of half-hole capabilities and a wide thickness range further establish its superiority in the HDI PCB market. With this board, designers and engineers can confidently push the boundaries of what’s possible in electronic design, safe in the knowledge that they are working with a product that embodies the pinnacle of modern PCB technology.

Features:

- Product Name: HDI PCB Board

- Aspect Ratio: 10:1

- Pcb Name: 4L 1+N+1 HDI Boards

- Thickness: 0.4-3.2mm

- Testing: 100%E-Testing, X-RAY

- Board Layer: 6L

- Compatible with HD SDI Converter

- Designed for DDR4 PCB applications

Technical Parameters:

| Parameter |

Specification |

| Impedance Control |

Yes |

| Board Thickness |

0.2mm-6.00 mm (8mil-126mil) |

| Testing |

100%E-Testing, X-RAY |

| Minimum Hole Size |

0.15mm |

| Aspect Ratio |

10:1 |

| Thickness |

0.4-3.2mm |

| Board Layer |

6L |

| Min Trace |

3/3Mil |

| Pcb Name |

4L 1+N+1 HDI Boards |

| Special Request |

Half Hole, 0.25mm BGA |

Applications:

The HDI (High Density Interconnector) Printed Circuit Boards, particularly the 4L 1+N+1 HDI Boards, are at the forefront of advanced PCB technology, catering to applications where space, weight, and functionality are critical. These boards, known for their high layer count and fine features, are perfect for scenarios where dense component placement and intricate routing are required. The HDI PCB Manufacturing process has evolved to meet the demands of modern electronics, allowing for the creation of boards with high-precision features such as Half Hole and 0.25mm BGA (Ball Grid Array) specifications.

One application scenario for the 4L 1+N+1 HDI Boards is in the realm of high-performance computing devices, where the minimum hole size of 0.15mm and the ability to implement 0.1mm Laser Drill holes become essential. These features enable the dense packing of vias, which is particularly important for multi-core processors and high-speed memory chips that require numerous connections to other components within a compact space. The HDI PCBs' fine pitch and high connection density are instrumental in achieving the performance goals of these devices.

Another scenario where these HDI boards are indispensable is in the field of medical electronics. Devices such as portable ultrasound machines or compact MRI systems, which often have special requirements like a Lamp Socket, rely on HDI technology to maintain a small form factor while delivering high-quality imaging and diagnostics. The precision with which the HDI PCBs are manufactured ensures the reliability and functionality required for critical medical applications.

Additionally, the HDI PCBs play a pivotal role in the aerospace and defense industries, where systems must withstand extreme conditions while maintaining peak performance. Complex military communication devices, avionics, and satellite systems often incorporate HDI technology to achieve the necessary robustness and functionality within the constraints of aerospace engineering.

Consumer electronics such as smartphones, tablets, and cameras also benefit from HDI PCBs. The drive towards thinner, lighter, and more powerful devices means that components like the HD SDI Converter, which is used for high-definition video transmission, must be accommodated within shrinking footprints. The 4L 1+N+1 HDI Boards, with their advanced capabilities, are integral to this miniaturization trend, enabling the continued evolution of consumer technology.

In conclusion, the HDI Printed Circuit Boards are essential for a multitude of high-tech applications, offering the precision and reliability that modern electronic devices require. From the intricate circuitry needed in HDI PCB Manufacturing to the specialized requirements of devices like those with Lamp Sockets, HDI PCBs like the 4L 1+N+1 HDI Boards are at the heart of innovation across industries.

Customization:

Our HDI PCB Board product, the 4L 1+N+1 HDI Boards, is crafted using high-quality FR4 IT180 raw material to ensure durability and optimal performance. This high density model board is designed to accommodate specialized requirements, featuring an impressive aspect ratio of 10:1 for precise and detailed circuitry.

Understanding the necessity for meticulous customization, we offer services to cater to special requirements such as the integration of a lamp socket. Additionally, our HDI PCB is engineered to support a minimum hole size of 0.15mm, allowing for tight tolerances and high-precision interconnects.

Support and Services:

The HDI PCB Board is a high-density interconnect printed circuit board designed for advanced electronic applications. Our product technical support for the HDI PCB Board includes comprehensive services to ensure optimal performance and reliability of your board. Our team of experienced engineers is available to provide assistance with design considerations, material selection, stack-up recommendations, and technical troubleshooting.

Our support services cover a wide range of technical aspects such as impedance control, via structure analysis, and thermal management. We provide guidance on best practices for layout and assembly processes to ensure the integrity of the final product. We also offer advice on signal integrity issues and can assist with EMC/EMI considerations to maintain compliance with industry standards.

For existing products, we offer diagnostic support to help identify and resolve any issues that may arise during the lifecycle of your HDI PCB Board. This includes detailed analysis of any failures and recommendations for corrective actions to prevent future occurrences.

Please note that our technical support does not include physical repair services or on-site assistance. It is focused on providing the necessary guidance and information to ensure proper use and maintenance of the HDI PCB Board. For more complex issues or design services, we may refer you to one of our trusted partners who specialize in those areas.

We are committed to providing exceptional support to all our customers. If you have any technical questions or require further assistance with your HDI PCB Board, please reach out to our support team through the designated communication channels provided at the time of your purchase.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!