Product Description:

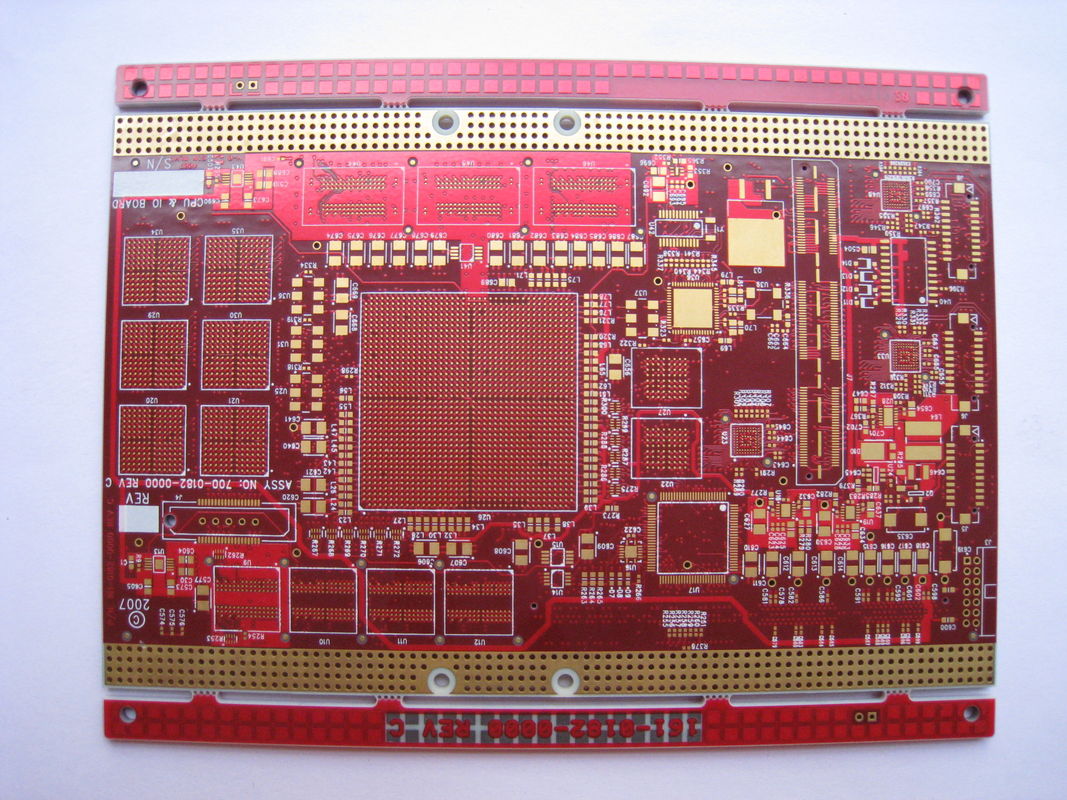

The HDI PCB Board is a prime example of cutting-edge technology in the realm of High Density Interconnector (HDI) circuit boards, tailored to meet the high-performance requirements of modern electronics. This product is meticulously crafted with a layer count ranging from 4 to 20 layers, providing a versatile platform for a wide array of applications. The HDI PCB Board is an exemplar of HDI PCB Manufacturing excellence, integrating a multitude of features designed for reliability and high-speed performance.

A standout feature of this HDI PCB is its ultra-fine hole size capabilities, with precision laser drilling technology that creates holes as small as 0.1mm. This level of detail is crucial for achieving the high-density component packing that these boards are renowned for. It enables electronics manufacturers to produce more compact devices without sacrificing functionality or performance, making it an ideal choice for applications such as HD SDI Converters, which require delicate and precise interconnections to handle high-definition signals.

Constructed from robust FR4 IT180 raw material, the HDI PCB Board is engineered to withstand the demands of high-speed and high-frequency applications. The use of FR4 IT180 material not only ensures the board's mechanical stability but also offers excellent thermal endurance, which is vital for maintaining the integrity of electrical pathways under extreme operating conditions. The material choice further underscores the product's suitability for advanced applications like DDR4 PCB, where consistent performance and reliability are non-negotiable.

In terms of physical robustness, the HDI PCB Board comes in a range of thicknesses from a slender 0.2mm to a sturdy 6.00mm (8mil-126mil). This range of board thicknesses provides designers with the flexibility to select the appropriate level of rigidity and durability for their specific application, whether it's a sleek, lightweight mobile device or a heavy-duty industrial machine. The HDI PCB's adaptability makes it an ideal substrate for a myriad of electronic components and systems.

The HDI PCB Board employs advanced manufacturing techniques to ensure the highest quality interconnections. Its fine line and space capabilities allow for denser routing of traces, which in turn supports the implementation of more complex circuitry within a compact area. This makes the HDI PCB an indispensable component in the development of sophisticated electronic devices, such as those that utilize HD SDI Converter technology, where space constraints and signal integrity are primary concerns.

Furthermore, the HDI PCB Board's design accommodates the need for high-speed signal transmission, a requirement that is paramount in DDR4 PCB applications. The precision-engineered board allows for efficient routing of DDR4 memory signals, reducing signal loss and cross-talk, and thereby enhancing the overall performance of the memory module. The exceptional electrical properties of the FR4 IT180 material complement the design, ensuring that the HDI PCB maintains signal integrity even at the high frequencies demanded by the latest DDR4 technology.

Manufacturers and designers opting for the HDI PCB Board can expect a product that embodies the pinnacle of HDI PCB Manufacturing. Every board is subjected to rigorous quality control measures to ensure that it meets the exacting standards demanded by modern electronics. The integration of features such as a 0.1mm laser drill hole size, versatile layer count, and the robustness of FR4 IT180 material, all contribute to a product that is not only high in quality but also versatile in its application to various high-tech industries.

In summary, the HDI PCB Board is a technologically advanced, high-quality product designed to cater to the ever-evolving needs of the electronics industry. It is a testament to the sophistication of HDI PCB Manufacturing, providing an essential foundation for devices that require high-density packaging, precision, and high-speed performance, such as HD SDI Converters and DDR4 PCBs. With its extensive range of features, the HDI PCB Board is poised to play a critical role in the development of the next generation of electronic devices.

Features:

- Product Name: HDI PCB Board

- Testing: 100% E-Testing, X-RAY

- Impedance Control: Yes

- Min Trace: 3/3Mil

- Raw Material: FR4 IT180

- Board Thickness: 0.2mm-6.00mm (8mil-126mil)

Technical Parameters:

| Technical Parameter |

Description |

| Impedance Control |

Yes |

| Layer Count |

4-20 Layers |

| Min Trace |

3/3Mil |

| Key Words |

High Density Interconnector, DDR4 PCB, High Density PCB, High Density Model Board |

| Special Request |

Half Hole, 0.25mm BGA |

| Raw Material |

FR4 IT180 |

| Aspect Ratio |

10:1 |

| Special Requirements |

Lamp Socket |

| Pcb Name |

4L 1+N+1 HDI Boards |

| Hole Size |

0.1mm Laser Drill |

Applications:

The HDI PCB Board, featuring advanced attributes such as impedance control, precise 0.1mm laser drill hole size, a high aspect ratio of 10:1, and thorough testing methods including 100% E-Testing and X-RAY, is tailored for high-performance and high precision applications. This board is especially suitable for scenarios that demand meticulous attention to detail and high reliability. Its capability to handle special requests like half holes and 0.25mm BGA positions it as an ideal choice for sophisticated electronics where space is at a premium and functionality cannot be compromised.

One of the primary application occasions for the HDI PCB Board is within the realm of High Density Interconnect applications or High Density Model Boards. These boards are integral to industries where the density of components is high, and the real estate on the board is particularly valuable. The High Density Model Board is a critical component in miniaturized consumer electronics such as smartphones, tablets, and laptops, where the efficient use of space is paramount, and the HDI PCB Board delivers on this need with finesse.

In addition, the HDI PCB Board is a key component in the manufacturing of HD SDI Converters. These converters are used in professional video applications where high-definition signals need to be transmitted without loss of quality. The precise impedance control ensures signal integrity over long distances, making the HDI PCB Board an indispensable element in the broadcast industry. This is particularly important in environments such as live event production, television studios, and outdoor broadcasts, where the stability and quality of the signal are of utmost importance.

Furthermore, the HDI PCB Board’s attributes are highly sought after in medical devices and aerospace technology. In these critical sectors, the reliability provided by the rigorous 100% E-Testing and X-RAY inspections ensure that each board meets the stringent quality standards required. The small hole size and high aspect ratio allow for a greater number of connections and functionality in a compact space, which is essential for intricate devices such as pacemakers, hearing aids, and satellite components.

Ultimately, the HDI PCB Board is a versatile and robust product that is well-suited for high-tech industries and applications where precision, reliability, and density are non-negotiable. Its specialized features cater to a broad range of scenarios, solidifying its role as a cornerstone in the production of cutting-edge electronic components and systems.

Customization:

Our High Speed PCB Board customization services cater to the most demanding HDI Printed Circuit Boards requirements in the industry. With options for Board Thickness ranging from a slender 0.2mm to a robust 6.00mm (8mil-126mil), our HDI PCB products are designed to meet the diverse needs of high-speed applications.

Our precision Hole Size capabilities include a 0.1mm Laser Drill, ensuring the utmost accuracy for your HDI PCB Board projects. The use of top-quality FR4 IT180 as our Raw Material guarantees the durability and performance expected from a premium High Speed PCB.

Impedance Control is a standard feature of our HDI PCB Board services, ensuring signal integrity and consistent electrical performance across your board. We also accommodate Special Requirements, such as Lamp Socket customizations, to ensure that our High Speed PCB solutions perfectly fit your specific applications.

Support and Services:

Our HDI PCB Board product comes with comprehensive technical support and services designed to ensure your success in integrating our boards into your projects. Our team of experts is well-versed in the complexities of HDI (High-Density Interconnect) technology and is ready to assist you with any challenges you may encounter.

Product Technical Support includes:

- Access to our online knowledge base and documentation, which provides detailed information on product specifications, handling instructions, and best practices for HDI PCB design and usage.

- Technical assistance from our skilled engineers who can help troubleshoot issues, provide design guidance, and offer practical tips for optimizing your PCB’s performance.

- Regular updates and patches to ensure your HDI PCB Board remains compatible with the latest technologies and standards in the industry.

Product Services include:

- Professional PCB layout and design consultation services to help you maximize the efficiency and reliability of your HDI PCBs.

- Option for a comprehensive design review service, where our experts examine your PCB design files to ensure they meet all necessary requirements for manufacturing and performance.

- Fast prototype service to help you test and refine your designs before moving on to full-scale production.

Please note that our technical support services are intended to assist with product-related inquiries and are subject to our standard terms and conditions. We strive to provide prompt and accurate support to all of our customers to ensure the highest level of satisfaction with our HDI PCB Board products.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!